Factors such as the working environment, site conditions, and fluid properties can all contribute to flow measurement deviations, which may often be calibrated through device setup. However, there are three additional types of flow deviations influenced by more complex factors. The following details from LORRIC provide insights into these critical parameters.

Note: Each of these parameters has distinct definitions. Users should avoid comparing data from different parameters, such as linearity and manufacturing flow deviation, directly.

1. Manufacturing Flow Deviation

Manufacturing flow deviation refers to the differences in product characteristics, such as weight, size, and appearance. LORRIC's paddle wheel flow meters feature a manufacturing flow deviation of within 2.5%, the lowest in the industry.

2. Flow Deviation of Measurement

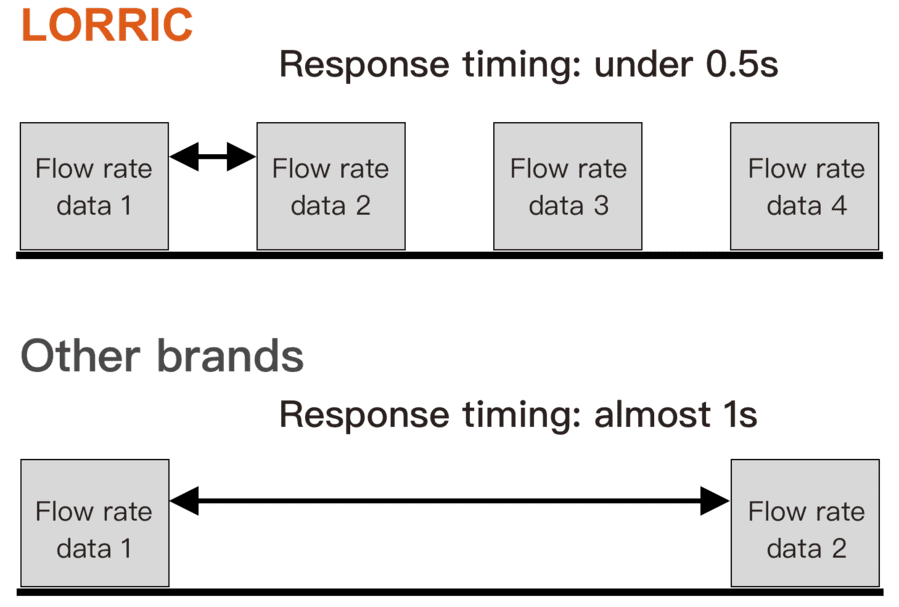

Measurement deviations can result from factors such as measurement duration, sensing conditions, and low velocity. For example, traditional paddle wheel flow meters face challenges at low velocities (e.g., 0.3m/s), where slow and inconsistent paddle rotation causes significant signal variation and measurement inaccuracies.

In contrast, LORRIC’s AxleSense technology captures even the slightest paddle rotation changes, delivering stable data within 0.5 seconds—much faster and more reliable than traditional models, which take approximately 1 second and may produce unstable readings.

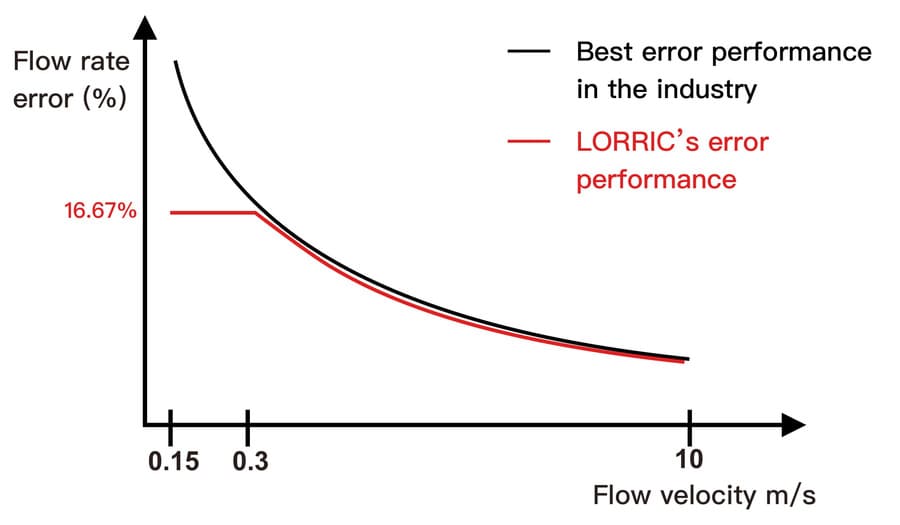

3. Linearity

1. Linear: Ideally, the output signals are proportional to the flow rate (y = ax). For example, the paddle's rotations in a flow meter correspond directly to the flow rate.

2. Linearity (F.S, or nonlinearity flow deviation): This represents the error between real output signals and the ideal linear output. Lower linearity corresponds to smaller flow deviations. LORRIC's AxleSense technology achieves a market-leading linearity of 0.5%.

At high velocities (e.g., 3m/s), paddle wheel flow meters exhibit linear performance. However, at lower velocities, the relationship becomes nonlinear due to physical factors such as flow field structure and friction within the device. LORRIC’s AxleSense technology excels in measuring low velocities (0.15–0.3m/s) with reduced flow deviation, achieving an error of 16.67% or less.