Factors such as the working environment, site conditions, fluid properties, and so on, may all cause the flow deviation of measurement but is possible to be calibrated through the device set-up. However, there are still three other kinds of flow deviation with greater effects caused by more complicated factors. Readers can refer to the following contents generated by LORRIC for reference to know more details about these three important parameters.

Each definition of these three parameters is different. Users need to take note that datas from different parameters, such as linearity and manufacturing flow deviation , can not be compared to each other at the same time.

1. Manufacturing Flow Deviation

It is the difference of manufacturing each product, such as weight, size, and appearance. The manufacturing flow deviation of LORRIC paddle wheel flowmeters are within 2.5% which is the lowest in the industry.

2. Flow Deviation of Measurement

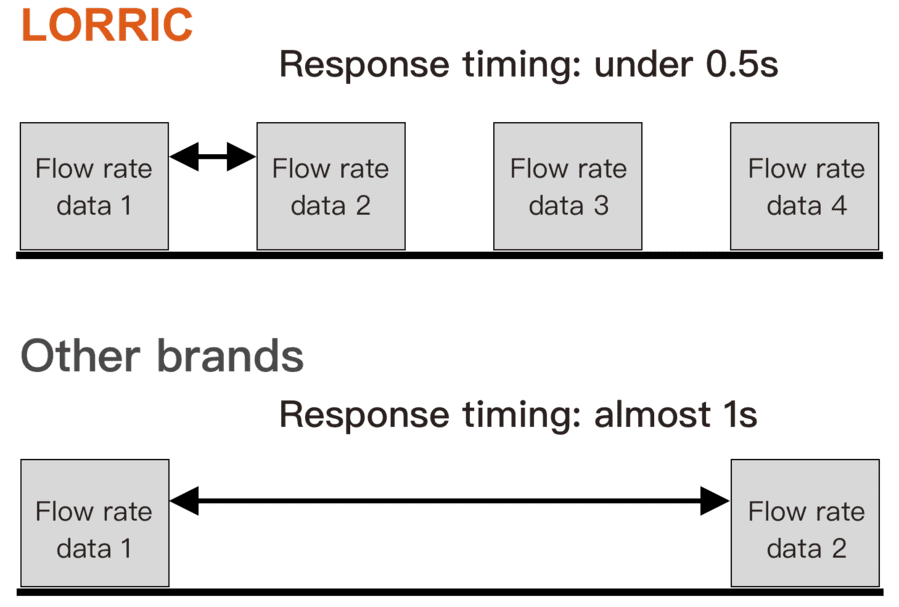

Factors like measurement duration, sensing condition, under low velocity, and so on, may cause the error of the output signal. For a general paddle wheel flowmeter, when it is under low velocity, the paddle will rotate very slowly without smoothness like at 0.3m/s. The paddle usually rotates a circle per second at most which is equal to 1 to 4 signals delivery and the duration of each signal may vary greatly which leads flow measurement to be varied greatly either. To solve this issue, the traditional paddle wheel flowmeter will try to extend its duration to receive more flow data. However, the result is still not ideal yet.

To compare with traditional paddle wheel flow meters, LORRIC paddle wheel flow meter with AxleSense technology is able to sense even the slightest change of paddle’s rotation angle and stably receive reliable data within 0.5s which takes almost 1s for the traditional one, and will not deliver any unstable data by not enough number of signals like the traditional paddle wheel will also do.

3. Linearity

1. Linear:

The output signals at any location are all proportional to the flow rate. Also, the input value is proportional to the output value, either (y= ax). For example, the number of rotations by the paddle in the paddle wheel flowmeter is proportional to the flow rate which is an ideal condition.

2. Linearity (F.S, aka nonlinearity flow deviation):

The input value is not proportional to the output value. Within the measuring range, linearity stands for the error between the real output signal and ideal linear output signal by the sensor which has to be received through the measurement. Lower linearity, smaller the flow deviation. LORRIC paddle wheel flowmeter with AxleSense technology provides the lowest linearity of 0.5% on the market.

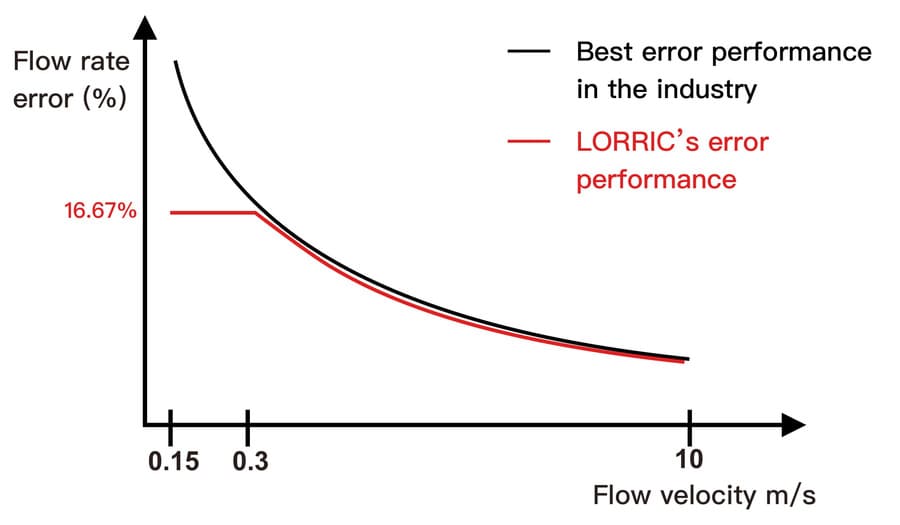

Under high velocity (e.g. 3m/s), in the paddle wheel flowmeter, the relationship between flow rate data and output signal is linear (proportional). On the contrary, it will be nonlinear (non-proportional). For example, we assume a signal is equal to a liter flow rate under high velocity, when the velocity is getting lower and lower, a signal will stand for 5 liters, which is a great difference. The factors that cause linearity are physical factors, like structure of flow field and product type. For example, to compare with electronic flowmeters, when the mechanical flowmeters are working, there will be friction generated inside it which makes nonlinear very obvious especially under the low velocity.

For most kinds of flowmeters, the flow measurement is not able to work when the flow velocity is under 0.3m/s. LORRIC’s patented technology, AxleSense, is very sensitive to the original data with quick response which can not only do well in flow measurement between 0.15~0.3m/s flow velocity, but also reduce the flow deviation to 16.67% or under.