Clamp on Flow Meter

The clamp on ultrasonic flow meter measures by attaching sensors to both sides of the pipe, requiring no cutting or interruption of flow during installation—ideal for situations where downtime is not an option.

This non-invasive method is ideal for contamination-free measurements in semiconductor processes, PCB manufacturing, and water treatment, offering high linearity and consistent accuracy at all flow rates.

ToF (Time of Flight) Principle

Using the formula Flow Rate = Cross-Sectional Area × Flow Velocity, accurate flow measurement depends on precisely measuring fluid velocity. The FU-ES ultrasonic flow meter, with EchoSense technology, calculates velocity by measuring the time difference of ultrasonic waves traveling with and against the flow (Time of Flight).

As shown in the diagram, ultrasonic signals move faster with the flow (A to B) and slower against it (B to A) due to the fluid's influence on wave speed. By measuring this time difference, the flow velocity is determined, and combined with the pipe's cross-sectional area, the flow rate can be accurately calculated.

Learn more: How to Calculate Flowrate

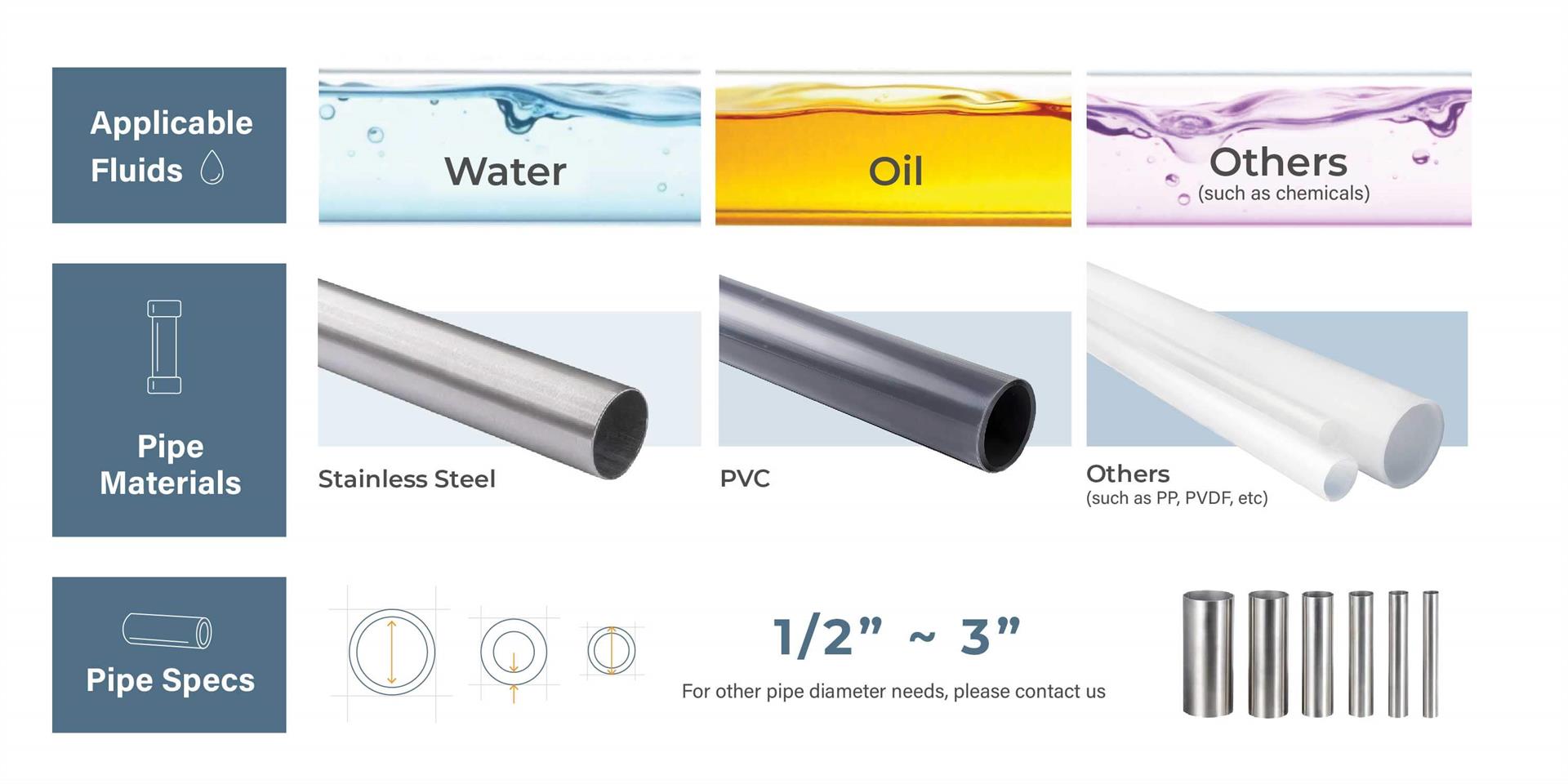

Applicable to variety of fluids, pipe materials and diameters

EchoSense ultrasonic flow meter is versatile, working with water, oil, and chemicals. It's compatible with stainless steel, PVC, and even PP, PVDF piping materials. With applications ranging from 1/2-inch to 3-inch pipes.

Say goodbye to costly ultra sonic gel; Welcome time and cost savings

LORRIC's "ultra sonic gasket pad" is a hassle-free solution that saves you both time and money. No more dealing with the mess and inconvenience of ultrasonic gel.

Complete all settings in 1 click

With EchoSense technology, forget about worrying over pipe materials, inner and outer diameters, thickness, liquid speed of sound, probe placement, and installation complexities. With just one click, we've simplified it all, making installation and setup a breeze. Say goodbye to the hassle!

Automatic Pipe Specification Matching

EchoSense technology features a built-in database of common pipe specifications, including PVC, PP, PVDF, and stainless steel. After installation, one click matches the installed pipe with the database, automatically setting material, outer diameter, and wall thickness. This streamlines installation by removing manual configuration and reducing errors, solving the issue of uncertain pipe specs in traditional setups.

Remarkable measurement accuracy

LORRIC's exclusive algorithm maintains high precision, earning Germany's TrigasFI certification. Test charts show FU-ES measurement accuracy between ±3.0% OR for 10%-100% of full scale (F.S.) and ±0.3% F.S. for 0%-10% of F.S. For a DN25 pipe (3-300LPM range), a 100LPM reading (10%-100%) has a ±3.0% error (97-103). A 20LPM reading (0%-10%) has a ±0.3% error (19.91-20.09).

Multiple Communication Outputs

FU-ES supports various communication modes like Analog output with self-powered 16-bit 4-20mA, Modbus RTU RS485, 2-wire photoelectric switch signal (compatible with NPN/PNP). No need for additional communication modules – we've got you covered!

Learn more:

•What is Analog Output

•What is Modbus RTU RS485

•What is Switch Signal

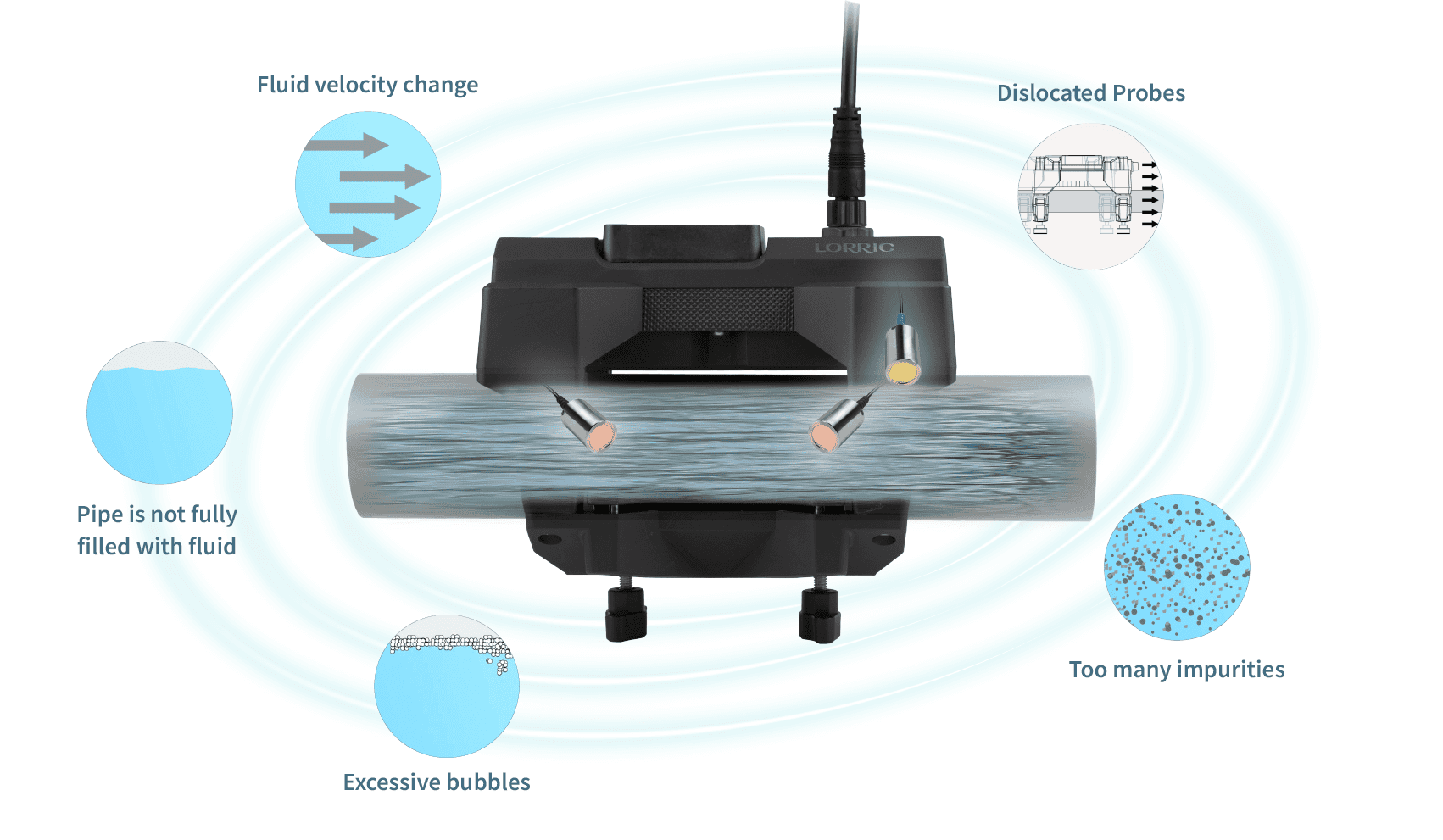

Detect problems instantly and intelligently with automatic environment sensing

Our ultrasonic flowmeter is engineered for smarter, more reliable performance with a dedicated third transducer designed for environmental sensing, allowing it to adapt seamlessly to changing flow conditions. This advanced feature continuously monitors critical factors like fluid sound velocity, incomplete pipe fills, and impurities, ensuring precise measurements while preventing disruptions. By detecting these variables in real time, it helps minimize downtime and keeps your operations running smoothly.

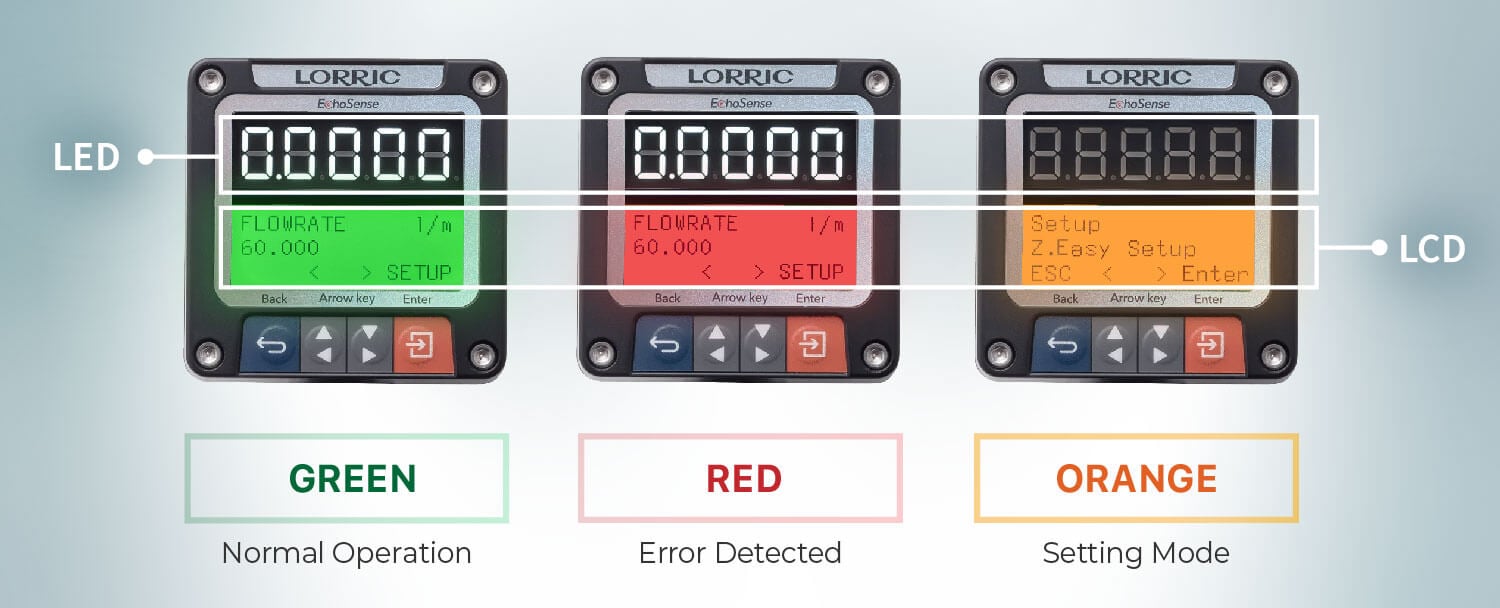

Dual LCD/LED screens for easy traffic and equipment status monitoring

- High-brightness large LED screen for easy long-distance flow number reading.

- LCD screen backlight with three-color warning light signal for visual monitoring of flow meter's normal and abnormal conditions.

Vertically and Horizontally Installable

The EchoSense ultrasonic flow meter screen features a square design, allowing for both vertical and horizontal installation to suit different usage scenarios. When installing at different angles, simply remove the screws on the four sides of the screen, rotate the screen 90 degrees, and reattach the screws. The display will easily adjust to the new orientation.

Elevate chemical resistance with our engineering plastic housing for the flowmeter.

Experience the Power of FU-ES! Crafted from robust engineering plastics like Nylon, PPS, and PEEK, its outer body boasts incredible strength. Inside, reinforced with 304 stainless steel, ensuring unmatched structural rigidity while prioritizing chemical resistance and product longevity.

|

FU-ES015 |

FU-ES020 |

FU-ES025 |

FU-ES032 |

FU-ES040 |

FU-ES050 |

FU-ES065 |

FU-ES075 |

| Installation Method |

Outside the pipe (clamp-on type) |

| Applicable Diameter |

| mm |

20-22 |

25-27.2 |

32-34 |

38-42.16 |

48-50 |

60-63 |

73-76.3 |

88.9-90 |

| inch |

0.79-0.87 |

0.98-1.07 |

1.26-1.34 |

1.5-1.66 |

1.89-1.97 |

2.36-2.48 |

2.87-3 |

3.5-3.54 |

| Applicable Pipe Material |

Metal pipe*, Plastic pipe (UPVC, PPH, PVDF) |

| Applicable Fluid |

Various liquids (no impurities or air bubbles) |

| Fluid Temperature |

0 ~ 85°C (no ice on the piping surface) |

| Velocity Range |

±0.3 to 6.0 m/s recommended, ±0.1 to 10m/s measurable |

| Flow Range |

| LPM |

1.5-120 |

2-200 |

3-300 |

5-470 |

8-770 |

13-1320 |

22-1670 |

30-1870 |

| GPM |

0.4-31.7 |

0.53-52.83 |

0.79-79.25 |

1.32-124.16 |

2.11-203.41 |

3.43-348.71 |

5.81-441.17 |

7.93-494 |

| Language |

English, Traditional & Simplified Chinese (others customizable) |

| Units |

Metric - Meters, Cubic Meters, Liters

Time - Seconds, Minutes, Hours, Days

Imperial - Feet, Cubic Feet, UK gallon, US gallon |

| Display Mode |

Dual screen display: 5-digit LED + 3-color backlight, 3-line 16-character LCD |

| Display Update Cycle |

0.5s, 1s |

| Measurement Accuracy |

±3.0% RD (10%-100% F.S.), ±0.3% F.S. (0%-10% F.S.)** |

| Display Resolution |

Max resolution 0.0001 (finest) |

| Power Demand |

DC 12V to 36V |

| Power I/O Connector |

M12 8-pin connector (2m cable) |

| Input/Output |

Analog output 4-20mA, Modbus RTU RS485, Two-wire optocoupler switch signal |

| Consumption Current |

<200mA@12V when starting up and working stably (not included in the communication current) |

| Protection Circuit |

Power reverse & surge protection |

| Waterproof Level |

IP66*** |

| Ambient Temperature |

-10 ~ 60°C (no freezing) |

| Relative Humidity |

35 ~ 85%RH (non-condensing) |

| Material |

PPS+GF, PEEK, NBR, Silicon, PA66+GF, PC+GF, SS304, PMMA |

Weight (g)

|

770

|

770

|

785 |

800 |

1390 |

1540 |

1580 |

1650 |

* For copper tubing, ensure correct outer diameter. Refer to table below.

** The measurement accuracy is established in a controlled laboratory environment where the pipe and fluid conditions are set and the instrument is calibrated to zero before conducting tests at 25°C. Although statistical results are obtained under these conditions, there may be variances in accuracy when used in customer environments.

*** Incorrect installation when rotating the screen by loosening the screws around it may affect the IP66 waterproof protection.

Outer Diameter Matters with Copper Tubing

| |

FU-ES 015 |

FU-ES 015 |

FU-ES 020

with modified clamp

|

FU-ES 025 |

FU-ES 032 |

FU-ES 040

w/o

Silicon plate

|

FU-ES 050

w/o

Silicon plate |

FU-ES 065

w/o

Silicon plate |

| OD mm |

19.05 |

22.23 |

28.58 |

34.93 |

41.28 |

53.98 |

66.68 |

79.38 |

Recommended

Specification |

FU-ES015

(Copper 19.05mm) |

FU-ES015

(Copper 22.23mm) |

FU-ES020

(Copper 28.58mm) |

FU-ES025

(Copper 34.93mm) |

FU-ES032

(Copper 41.28mm) |

FU-ES040

(Copper 53.98mm) |

FU-ES050

(Copper 66.68mm) |

FU-ES065

(Copper 79.38mm) |

*Note: Copper tubing is not compatible with the Z02 auto pipe size detection function. Manual input is required.

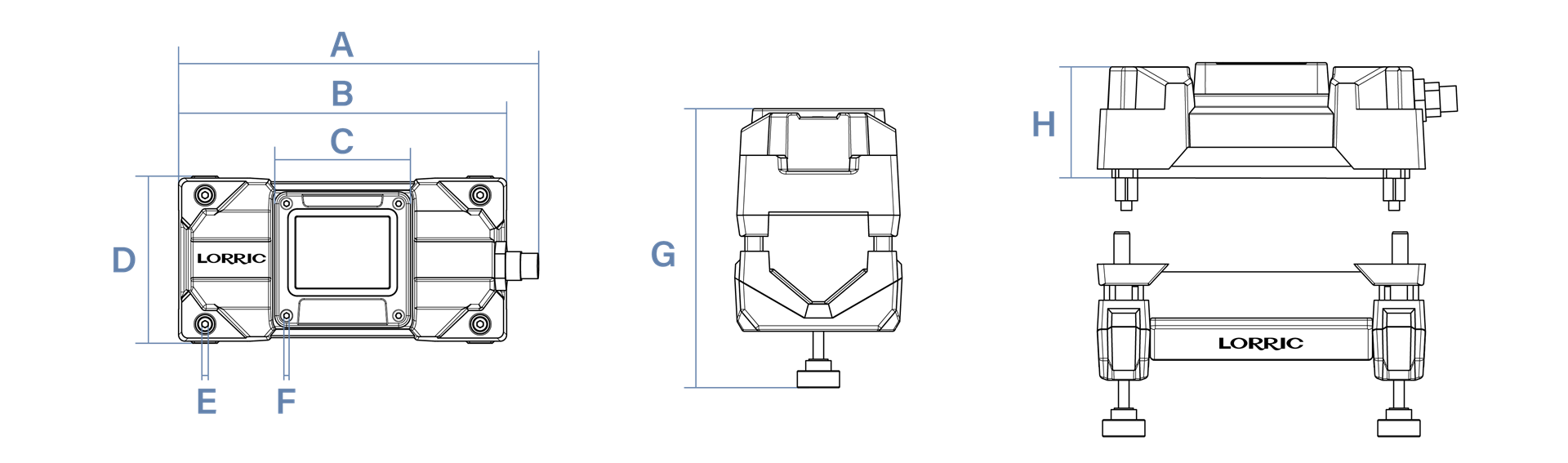

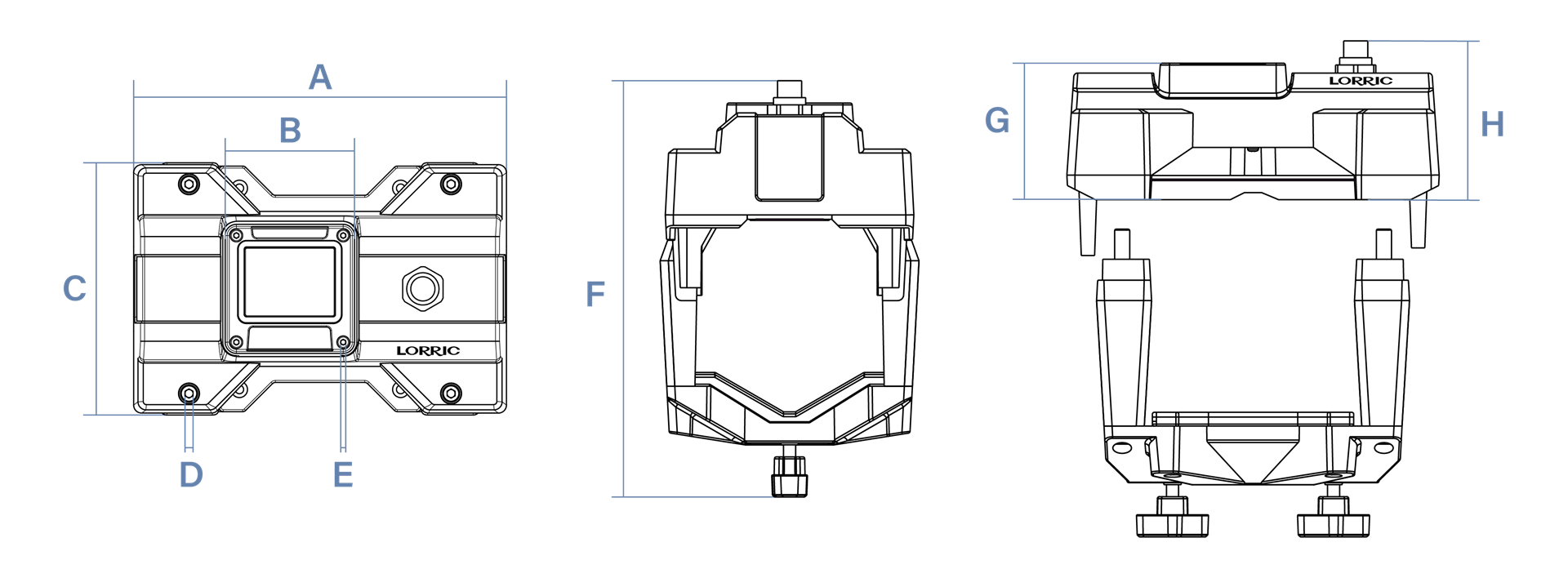

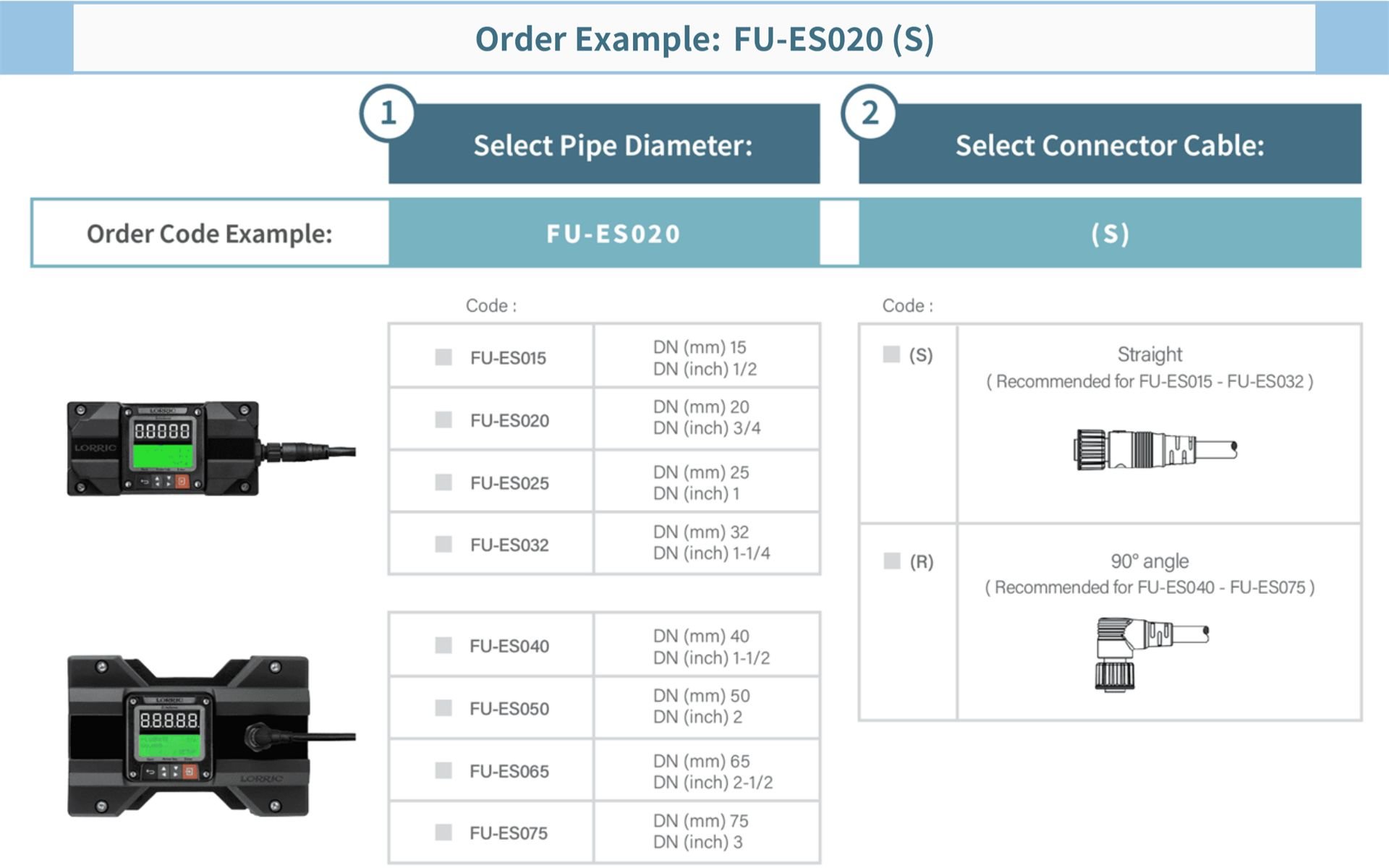

Size

FU-ES015 / FU-ES020 / FU-ES025 / FU-ES032

Unit:mm

| A

|

B

|

C

|

D

|

E

|

F

|

G |

H |

| FU-ES015 |

169.85 |

115 |

64 |

79 |

3 |

2.5 |

120.53 |

54 |

| FU-ES020 |

169.85 |

115 |

64 |

79 |

3 |

2.5 |

124.02 |

54 |

| FU-ES025 |

169.85 |

115 |

64 |

79 |

3 |

2.5 |

133.52 |

54 |

| FU-ES032 |

169.85 |

115 |

64 |

79 |

3 |

2.5 |

143.02 |

54 |

FU-ES040 / FU-ES050 / FU-ES065 / FU-ES075

Unit:mm

| A

|

B

|

C

|

D

|

E

|

F

|

G |

H |

| FU-ES040 |

184.90 |

64 |

125.22 |

4 |

2.5 |

164.12 |

53.50

|

69.50 |

| FU-ES050 |

184.90 |

64 |

125.30 |

4 |

2.5 |

178.12 |

53.50

|

69.50 |

| FU-ES065 |

184.90 |

64 |

126.87 |

4 |

2.5 |

193.12 |

53.50

|

69.50 |

| FU-ES075 |

184.90 |

64 |

128.55 |

4 |

2.5 |

207.12 |

53.50

|

69.50 |

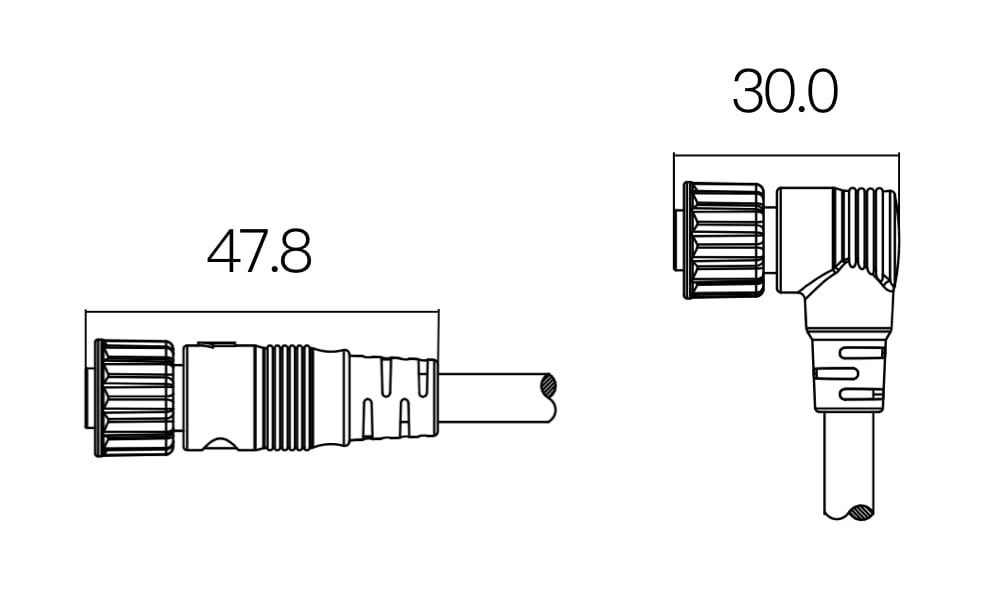

Cable Head Size

Please refer to the order example when placing your order

Responsive Product Video Section

Related Product Videos

Recommended Installation Location

Mechanical Installation

Electrical Installation

Applications

Semiconductor

Flow meters monitor chemical liquids and pure water treatment fluids supply; nozzles control the spraying of chemical liquids to ensure process purity and stability.

PCBs

Flow meters in PCB electroplating, developing, and etching processes monitor precise chemical and cleaning fluid flow; nozzles control chemical coating and rinsing

Wastewater Treatment

Flow meters monitor the flow of inlet and outlet water, enhancing treatment efficiency and accuracy; nzzles spray chemicals in wastewater treatment, meeting environmental standards

Purified Water Industries

Flow meters monitor water usage at each stage to control process efficiency; nozzles optimize water spray to ensure water purification efficiency and reduce treatment costs

Car Wash

Flow meters ensure cleaning efficiency and reduce water wastage; nozzles uniformly distribute water, enhancing the cleaning effect while simultaneously reducing water consumption

AC

Flow meters monitor and control cooling and hot water flows, tracking chiller energy use; nozzles balance water flow in these systems, enhancing efficiency

Steel Industries

Flow meters monitor cooling water and gas flow, ensuring accuracy and optimal efficiency; nozzles precisely control chemical liquid spraying, making even coating and stable quality

Healthcare Industry

The article covers dialysis basics, types (hemodialysis, peritoneal dialysis). It also highlights water treatment's importance and ultrasonic flow meters' role in data automation.