1. Electrostatic Discharge (ESD) Protection là gì?

Phóng tĩnh điện (ESD) là sự chuyển đổi đột ngột của điện tích tĩnh giữa hai vật thể có mức điện tích khác nhau. Điện tích tĩnh là sự mất cân bằng điện tích trong hoặc trên bề mặt của một vật liệu, dẫn đến sự hình thành trường điện. Sự mất cân bằng này có thể ảnh hưởng đến các vật thể xung quanh, và khi chênh lệch điện tích trở nên đáng kể, nó gây ra sự chuyển đổi tự phát của điện tích tĩnh – hiện tượng này được gọi là ESD.

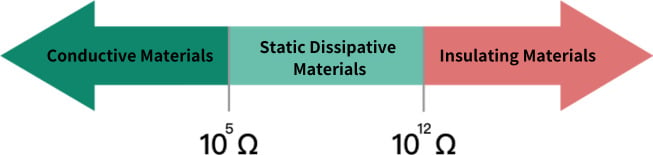

Để bảo vệ chống ESD, các vật liệu dẫn điện thường được thêm vào các chất cách điện. Bằng cách đưa vào các phần tử dẫn điện, vật liệu sẽ trở nên ít cách điện hơn, cho phép điện tích tĩnh dư thừa tiêu tán an toàn. Điều này giúp ngăn ngừa tác hại của ESD đối với các thành phần nhạy cảm, đảm bảo độ tin cậy và an toàn tốt hơn cho sản phẩm trong nhiều ngành công nghiệp.

2. Cảnh Báo! Bỏ Qua Phóng Tĩnh Điện (ESD) Của Vật Liệu Có Thể Gây Hư Hỏng Nặng Đến Sản Phẩm Của Bạn!

Trong sản xuất công nghiệp, phóng tĩnh điện (ESD) có thể làm hỏng linh kiện và gây gián đoạn thiết bị, đe dọa hiệu quả sản xuất. Các thiết bị điện tử nhạy cảm, như vi mạch tích hợp (ICs), đặc biệt dễ bị ảnh hưởng, ngay cả một phóng tĩnh điện nhỏ cũng có thể dẫn đến hỏng hóc sản phẩm hoặc giảm tuổi thọ. ESD cũng gây ra rủi ro đối với an toàn của con người. Để ngăn chặn những vấn đề này, việc kiểm soát tĩnh điện nghiêm ngặt là cần thiết, đảm bảo chất lượng sản phẩm và an toàn cho người lao động.

3. Tổng Quan về Khả Năng Chống Phóng Tĩnh Điện (ESD)

ESD, hay phóng tĩnh điện, là sự mất cân bằng của điện tích trong hoặc trên bề mặt của một vật liệu. Sự mất cân bằng này tạo ra một trường điện có thể ảnh hưởng đến các vật thể khác. ESD được định nghĩa là sự chuyển đổi nhanh và tự phát của điện tích tĩnh do một trường tĩnh điện cao gây ra. Bằng cách thêm các chất dẫn điện vào các vật liệu cách điện, chúng có thể giảm tính cách điện, cho phép các electron tĩnh được tiêu tán.

4. Khả năng Chống Phóng Tĩnh Điện (ESD)

Roechling đề xuất các phương pháp và thiết bị sau đây để kiểm tra xem liệu các vật liệu hiện tại của bạn có tuân thủ ESD hay không, chủ yếu được chia thành hai loại.

- Loại bề mặt: Sử dụng hai dải điện cực dài bên trong, giống như các đường rãnh, phù hợp với các vật liệu phẳng nhưng không phù hợp cho vật liệu hình thanh hoặc kích thước nhỏ do có thể gặp vấn đề về tiếp xúc, dẫn đến đọc giá trị điện trở cao không chính xác.

Khi kiểm tra vật liệu, điều quan trọng là không thực hiện các bài kiểm tra trực tiếp trên bề mặt của các vật liệu dạng thanh vừa được sản xuất. Do quá trình gia nhiệt và tạo hình trong sản xuất, bề mặt của các thanh này bị oxy hóa đáng kể, dẫn đến các giá trị đo không chính xác. Do đó, để thu được dữ liệu chính xác, cần loại bỏ bề mặt của vật liệu trước khi đo.

- Loại bút: Có hai điện cực ở đầu bút để chạm và đo các vật liệu dạng thanh.

Nếu bạn không chắc chắn liệu vật liệu của mình có tuân thủ ESD hay không, bạn có thể cung cấp cho chúng tôi một mẫu vật liệu hiện đang sử dụng. Chúng tôi có thể hỗ trợ gửi mẫu này đến phòng thí nghiệm Roechling tại Đức để kiểm tra và xác nhận liệu nó có đạt tiêu chuẩn vật liệu ESD hay không. Nếu bạn cần vật liệu ESD, vui lòng liên hệ với chúng tôi để được tư vấn.

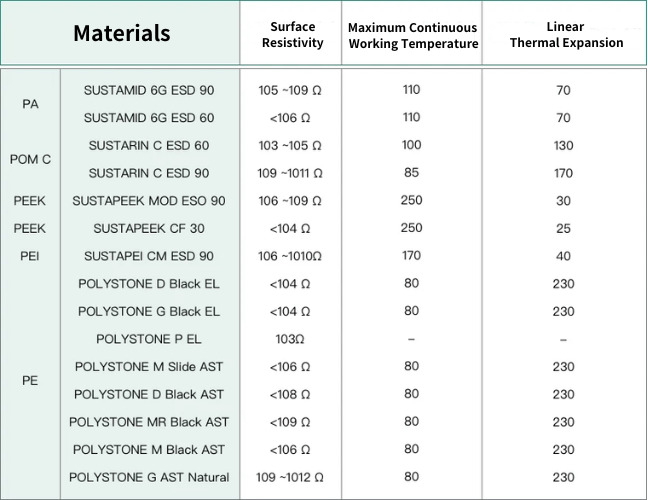

5. Vật Liệu ESD Chất Lượng Cao của Roechling: Giải Quyết Vấn Đề Tĩnh Điện của Bạn

Nhiều nhà sản xuất nhựa thêm quá nhiều chất chống tĩnh điện vào sản phẩm để ngăn chặn tĩnh điện, vô tình biến chúng thành vật liệu dẫn điện và làm giảm các đặc tính vật lý, chẳng hạn như khả năng chống mài mòn và độ bền. Khác với các sản phẩm khác, vật liệu của Roechling vượt trội về hiệu suất, cho phép lựa chọn vật liệu chống tĩnh điện mà không làm ảnh hưởng đến các đặc tính quan trọng khác của vật liệu.

6. Chọn vật liệu ESD của Roechling: