1. What is Electrostatic Discharge (ESD) Protection?

Electrostatic discharge (ESD) refers to the sudden transfer of static electricity between two objects with different charge levels. Static electricity itself is an imbalance of electric charge either within or on the surface of a material, leading to the creation of an electric field. This imbalance can influence nearby objects, and when the charge difference becomes significant, it results in a spontaneous transfer of static charge—this is the phenomenon known as ESD.

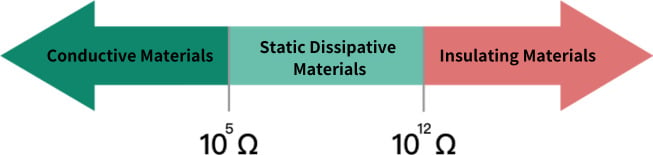

To protect against ESD, conductive materials are often added to what would otherwise be insulative substances. By introducing these conductive elements, the material becomes less insulating, allowing excess static electricity to dissipate safely. This helps to prevent the damaging effects of ESD on sensitive components, ensuring better product reliability and safety across industries.

2. Beware! Ignoring Material Electrostatic Discharge (ESD) Can Severely Damage Your Products!

In industrial manufacturing, electrostatic discharge (ESD) can damage components and disrupt equipment, threatening production efficiency. Sensitive electronics, like integrated circuits (ICs), are particularly vulnerable, with even minor static discharge leading to product failure or reduced lifespan. ESD also poses risks to human safety.

To prevent these issues, strict electrostatic control is essential, safeguarding both product quality and worker safety.

3. An Overview of Electrostatic Discharge (ESD) Resistance

ESD, or Electro Static Discharge, refers to an imbalance of electric charges within or on the surface of a material. This imbalance creates an electric field that can affect other objects. ESD is defined as the rapid, spontaneous transfer of static charges induced by a high static field. By incorporating conductive substances into insulating materials, they can be made less insulating, allowing static electrons to be dissipated.

4. Confirming Your Materials as ESD Compliant

Roechling suggests the following methods and instruments for testing whether your current materials are ESD compliant, mainly categorized into two types.

- Surface type: Uses two long electrode strips internally, resembling tracks, suitable for flat materials but not for rod-shaped or small-sized materials due to potential contact issues leading to inaccurately high resistance readings.

When testing materials, it's crucial not to conduct tests directly on the surface of newly manufactured rod materials. Due to the heating and molding process involved in their production, the surface of these rods is significantly oxidized, leading to inaccurate measurement values. Therefore, to obtain precise data, the surface of the material must be removed before measurement.

- Pen type: Features two electrodes at the pen tip for touching and measuring rod-shaped materials.

If you're uncertain about whether your materials are ESD compliant, you can provide us with a sample of the material currently in use. We can assist in sending it to the Roechling laboratory in Germany for testing, to confirm whether it meets ESD material standards. If you require ESD materials, please feel free to call us for consultation.

5. Roechling's High-Quality ESD Materials: Solving Your Static Troubles

Many plastic manufacturers add excessive antistatic substances to their products to prevent static, inadvertently turning them into conductive materials and compromising their physical properties, such as wear resistance and strength. Unlike others, Roechling materials excel in performance, allowing for the selection of antistatic materials without sacrificing other critical material properties.

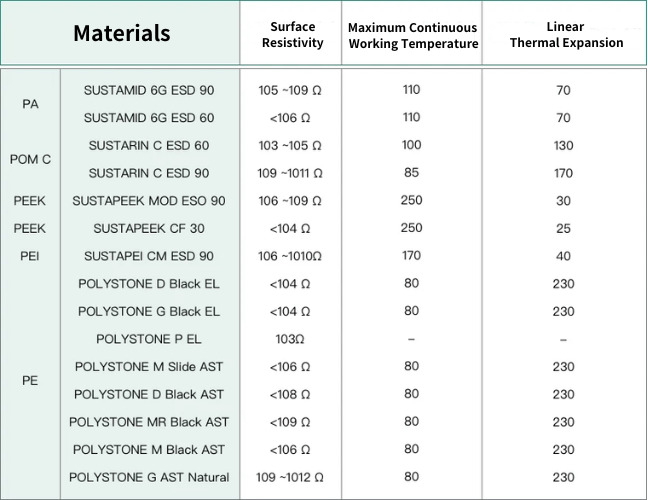

Roechling ESD Material Selection