Thị trường cung cấp hàng trăm loại van. Tuy nhiên, chúng có thể được phân loại rộng rãi thành ba loại dựa trên chuyển động của chúng: van chuyển động tuyến tính, van chuyển động xoay và van quay một phần. Dưới đây là 11 loại van phổ biến được phân loại theo loại chuyển động của chúng:

Chuyển động mở và đóng của van chuyển động tuyến tính theo một đường thẳng. Thanh van di chuyển lên và xuống bên trong thân van để mở hoặc đóng van, cho phép đĩa van tiếp xúc chặt chẽ với ghế van. Điều này thường dẫn đến hiệu suất niêm phong tốt. Các loại van chuyển động tuyến tính phổ biến bao gồm

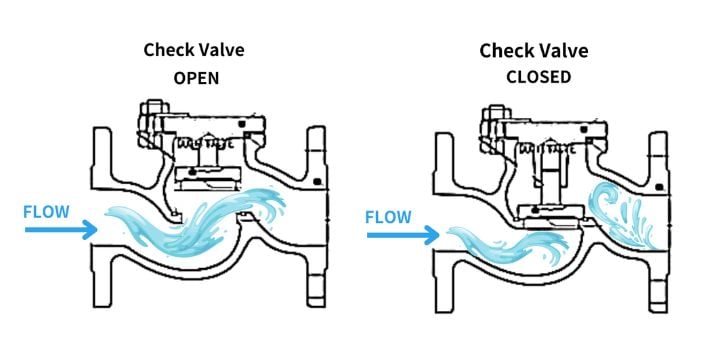

a. Van Một Chiều

Van một chiều, còn được gọi là van không trở lại, chủ yếu được sử dụng để ngăn chặn dòng chảy ngược của chất lỏng. Chúng có nhiều loại khác nhau và được sử dụng rộng rãi trong các hệ thống thủy lực. Nhờ kích thước nhỏ gọn, cấu trúc đơn giản và chi phí thấp, van một chiều thường được tìm thấy trong các ứng dụng gia đình.

| Ưu điểm |

Nhược điểm |

| 1. Ngăn chặn dòng chảy ngược của chất lỏng. |

1. Có thể ảnh hưởng đến áp suất hệ thống. |

| 2. Cấu trúc đơn giản và chi phí thấp. |

2. Chỉ phù hợp với dòng chảy một chiều. |

| 3. Ứng dụng đa dạng. |

|

| 4. Yêu cầu bảo trì thấp. |

|

| 5. Hoạt động tự động. |

|

[3]

Như được thể hiện trong sơ đồ, van một chiều hoạt động như sau: áp suất chất lỏng đẩy van mở, cho phép chất lỏng chảy qua. Nếu chất lỏng cố gắng chảy ngược, van sẽ đóng lại, và áp suất ngược càng lớn thì khả năng niêm phong càng tốt. Van một chiều thường sử dụng lò xo hoặc trọng lực để đóng và không yêu cầu vận hành thủ công.

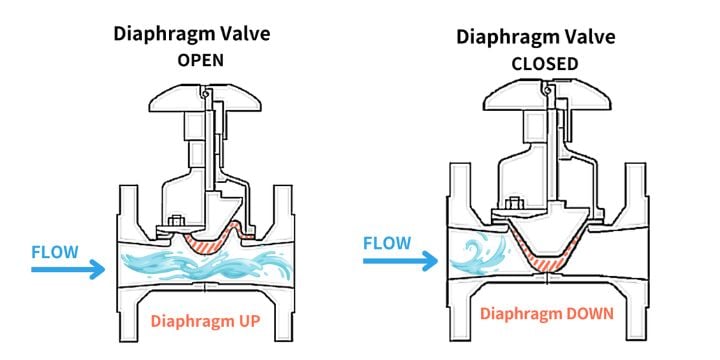

b. Van Cơ Bản

Van cơ bản điều khiển dòng chảy của chất lỏng bằng cách sử dụng một màng linh hoạt để bịt kín đường dẫn dòng chảy. Các van này lý tưởng cho các ứng dụng yêu cầu khả năng chống ăn mòn, khiến chúng thường được sử dụng trong ngành hóa chất để xử lý nhiều loại hóa chất, dung môi và môi trường ăn mòn.

Van cơ bản cũng thường được sử dụng trong ngành thực phẩm và dược phẩm, vì chúng hiệu quả trong việc ngăn chặn sự ô nhiễm chéo và đảm bảo vệ sinh cũng như an toàn cho các chất lỏng.

[4]

| Ưu điểm |

Nhược điểm |

| 1. Khả năng làm kín tuyệt vời. |

1. Khả năng chịu áp suất hạn chế. |

| 2. Kháng ăn mòn cao, phù hợp với các chất lỏng ăn mòn. |

2. Không phù hợp với môi trường nhiệt độ cao. |

| 3. Không có không gian chết, giảm thiểu tích tụ cặn và đáp ứng tiêu chuẩn vệ sinh cao. |

3. Phạm vi điều chỉnh dòng chảy hẹp. |

[5]

Như được thể hiện trong sơ đồ, van cơ bản bao gồm một màng đàn hồi bên trong thân van và nắp van. Khi thanh van nâng lên, màng sẽ được nâng lên, cho phép chất lỏng chảy qua. Việc hạ thanh van sẽ làm cho màng chặn miệng vào, ngăn dòng chảy.

Sự tách biệt giữa cơ chế điều khiển và chất lỏng thông qua màng đảm bảo khả năng niêm phong tuyệt vời, khiến van cơ bản trở thành lựa chọn lý tưởng cho các chất lỏng ăn mòn, bùn có sợi, chất lỏng phóng xạ hoặc các ứng dụng khác yêu cầu vận hành không bị ô nhiễm.

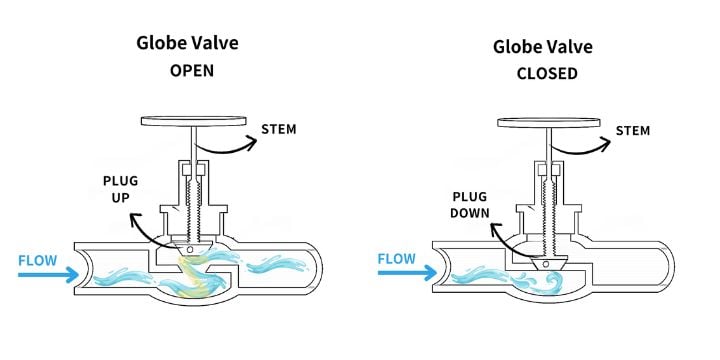

c. Van Cầu

Van cầu, còn được gọi là van chặn, điều chỉnh dòng chảy và áp suất và rất đa năng. Ban đầu được đặt tên theo hình dạng hình cầu của chúng, hiện nay đôi khi được gọi là van chặn để tránh nhầm lẫn với van bi.

Van cầu thường được sử dụng trong các hệ thống trao đổi nhiệt, cho phép dòng chảy chất lỏng trực tiếp, làm cho chúng phù hợp cho các chất lỏng có độ nhớt cao. Chúng rất lý tưởng cho các ứng dụng trong xử lý nước, hóa chất, dầu khí và hệ thống hơi, vì chúng ngăn ngừa sự tích tụ và đông đặc chất lỏng bên trong van.

[6]

| Ưu điểm |

Nhược điểm |

| 1. Kháng lực thấp nhờ đường chảy thẳng. |

1. Nhiệt độ hoạt động bị giới hạn bởi vật liệu ghế van. |

| 2. Có sẵn nhiều kích cỡ, đáp ứng phạm vi ứng dụng rộng. |

2. Kháng dòng chảy cao hơn so với các loại van khác. |

| 3. Phù hợp với tần suất hoạt động cao. |

3. Khá nặng về trọng lượng. |

| 4. Tổn thất ma sát thấp, đảm bảo tuổi thọ lâu dài. |

|

Van cầu hoạt động như sau: xoay tay cầm sẽ nâng trục van lên. Khi van cầu mở, lõi van di chuyển lên trên, cho phép chất lỏng đi qua. Dòng chất lỏng chảy theo một đường cong hình chữ Z bên trong van, vào ở vị trí thấp và ra ở vị trí cao, điều này làm tăng kháng lực và giảm áp suất. Để đóng van, lõi van hạ xuống, tiếp xúc chặt với đế van, tạo thành một lớp kín để ngăn dòng chảy của chất lỏng.

Trong quá trình vận hành, chất lỏng chảy trực tiếp từ đầu vào đến đầu ra theo một đường thẳng, giảm thiểu hiện tượng xoáy và ngưng tụ bên trong van, giúp ngăn chặn các chất lỏng có độ nhớt cao không bị đông đặc hay tích tụ. Van cầu thường được sử dụng trong các hệ thống xử lý nước, ngành công nghiệp hóa chất, dầu mỏ và hệ thống hơi nước.

[7][8]

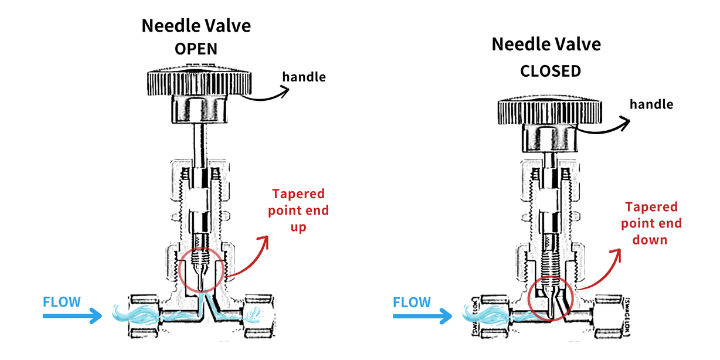

d. Van kim (Needle Valve)

Van kim có đặc điểm là lõi van hình kim vừa khít với đế van, cho phép kiểm soát chính xác lưu lượng chất lỏng ở áp suất thấp. Van kim lý tưởng cho các ứng dụng yêu cầu lưu lượng nhỏ hoặc ổn định ở mức thấp, chẳng hạn như trong các hệ thống chân không, ống dẫn khí, laser khí, và các thiết bị tương tự, cũng như điều chỉnh lưu lượng nhiên liệu khi nhàn rỗi trong bộ chế hòa khí.

Hiệu ứng Vernier trong van kim:

Do hình dạng nón của lõi van kim, khi điều khiển di chuyển theo chiều dọc trục (tức là lõi van di chuyển vào và ra), một sự khác biệt về đường kính giữa van kim và đế van được tạo ra. Hiệu ứng Vernier này, với thay đổi nhỏ về bán kính, là cơ chế chính để kiểm soát lưu lượng chính xác của van kim.

| Ưu điểm |

Nhược điểm |

| 1. Kiểm soát chính xác lưu lượng nhỏ. |

1. Không phù hợp với lưu lượng lớn. |

| 2. Phù hợp cho các hoạt động ở áp suất thấp. |

2. Tổn thất áp suất cao hơn. |

| 3. Có thể sử dụng trong các hệ thống chân không. |

|

| 4. Cấu trúc nhỏ gọn với khả năng làm kín tốt. |

|

[9][10]

Cấu trúc van kim bao gồm một lỗ nhỏ với ghế van dạng nón dài, có thể xoay vào hoặc ra để điều chỉnh độ mở của lỗ. Đầu vít có một lõi hình kim, khi đóng hoàn toàn, lõi này vừa khít với ghế van, cho phép điều chỉnh lưu lượng rất nhỏ một cách chính xác.

Do hạn chế về chiều cao của thân van, van kim gây ra tổn thất áp suất đáng kể trong dòng chảy. Thêm vào đó, ống dẫn hẹp của van làm tăng nguy cơ hư hại do các hạt rắn lơ lửng trong chất lỏng gây ra.

Van chuyển động quay hoạt động bằng cách xoay quanh một trục để mở hoặc đóng dòng chảy. Lõi van thường xoay để điều khiển đường dẫn dòng, mở hoặc đóng van tùy theo hướng xoay của nó.

Loại van này thường được sử dụng trong các ứng dụng yêu cầu vận hành nhanh và hiệu quả, vì chuyển động quay giúp kiểm soát lưu lượng dễ dàng và nhanh chóng.

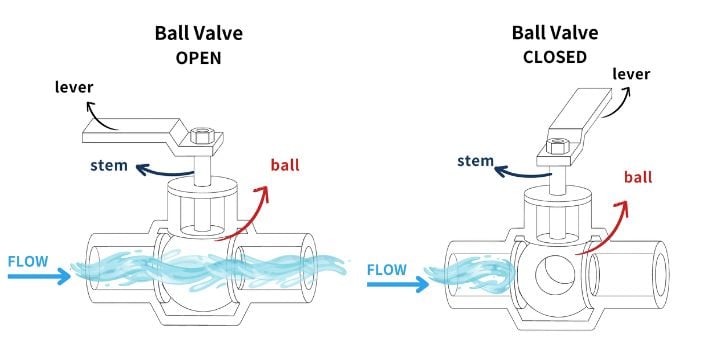

a. Van bi (Ball Valve)

Van bi kiểm soát dòng chảy chất lỏng bằng cách sử dụng một viên bi hình cầu có lỗ xuyên qua trung tâm. Loại van này cung cấp khả năng làm kín tuyệt vời và yêu cầu bảo trì tối thiểu. Do thao tác đơn giản, van bi rất lý tưởng cho các ứng dụng cần đóng ngắt nhanh chóng và làm kín đáng tin cậy.

Van bi được sử dụng rộng rãi trong nhiều lĩnh vực, bao gồm đường ống dầu khí công nghiệp, quy trình hóa chất và hệ thống cấp nước dân dụng.

[11]

| Ưu điểm |

Nhược điểm |

| 1. Có khả năng xử lý áp suất cao và lưu lượng lớn. |

1. Có thể xảy ra tình trạng tích tụ cặn giữa bi và ghế van. |

| 2. Hiệu suất làm kín tuyệt vời. |

2. Yêu cầu mô-men vận hành cao hơn, có thể cần thêm cơ cấu truyền động. |

| 3. Kháng dòng chảy thấp và dễ bảo trì. |

3. Kích thước thường lớn và nặng hơn. |

| 4. Có thể sử dụng để điều chỉnh và chuyển hướng dòng chảy. |

|

[12]

Van bi có lõi hình cầu rỗng với lỗ khoan có đường kính bằng với đường ống. Tay cầm xoay trục van để quay lõi bi. Khi lỗ khoan thẳng hàng với đường dẫn dòng chảy, chất lỏng đi qua. Để đóng kênh dòng chảy, tay cầm xoay 90 độ, chặn dòng chảy của chất lỏng.

Cơ chế xoay này cho phép van bi đóng mở nhanh chóng và đảm bảo làm kín hiệu quả, thích hợp cho các ứng dụng yêu cầu đóng ngắt dòng chảy tức thì và kiểm soát chặt chẽ.

[13][14]

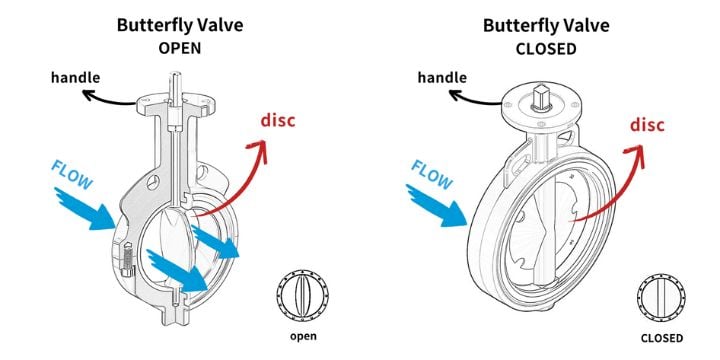

b. Van bướm (Butterfly Valve)

Van bướm, hay còn gọi là van cánh bướm, có thiết kế đơn giản và hoạt động nhanh chóng bằng cách xoay một đĩa để điều khiển dòng chảy. Van bướm thích hợp để quản lý khối lượng lớn chất lỏng hoặc khí ở áp suất thấp. Loại van này rất linh hoạt và có thể xử lý nhiều loại môi chất, bao gồm nước, dầu, hơi nước và chất lỏng ăn mòn.

Van bướm được sử dụng phổ biến trong xử lý nước, công nghiệp hóa chất và hóa dầu, hệ thống HVAC và tưới tiêu nông nghiệp.

Các loại van bướm khác nhau phù hợp với các mức áp suất và ứng dụng khác nhau:

i. Van bướm đồng tâm: Loại này có ghế cao su linh hoạt và đĩa kim loại, thích hợp cho các mức áp suất thấp nhất.

ii. Van bướm lệch tâm kép (hiệu suất cao hoặc lệch tâm kép): Ghế và đĩa sử dụng các vật liệu khác nhau, cho phép hoạt động ở dải nhiệt độ và áp suất rộng hơn.

iii. Van bướm lệch tâm ba (lệch tâm ba): Có ghế kim loại dạng lớp hoặc rắn, lý tưởng cho các hệ thống áp suất cao và môi trường khắc nghiệt, thường được sử dụng trong các ngành công nghiệp và năng lượng.

[15][16]

| Ưu điểm |

Nhược điểm |

| 1. Hoạt động nhanh, lý tưởng cho việc sử dụng thường xuyên. |

1. Dòng chảy không tuyến tính, gây áp suất không đều. |

| 2. Nhỏ gọn, nhẹ và dễ vận hành. |

2. Khả năng làm kín kém hiệu quả hơn. |

| 3. Kiểm soát dòng chảy tốt. |

3. Có thể rung hoặc phát ra tiếng ồn ở tốc độ cao. |

| 4. Tổn thất áp suất thấp khi mở hoàn toàn. |

4. Không phù hợp với nhiệt độ cực cao hoặc điều kiện áp suất cao. |

Như được thể hiện, van bướm bao gồm một đĩa quay thường được đặt ở trung tâm của thân van. Trong quá trình hoạt động, đĩa hình tròn quay quanh một trục với góc tối đa 90 độ, điều chỉnh dòng chảy của môi chất bằng cách thay đổi góc.

Vì đĩa luôn có mặt trong chất lỏng, nó làm tăng trở kháng dòng chảy, gây ra tổn thất áp suất cục bộ.

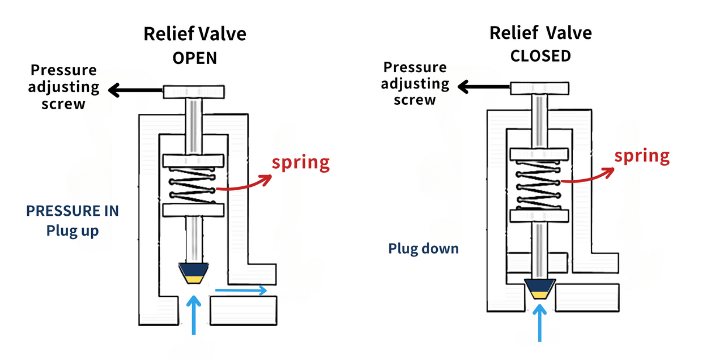

c. Van Giảm Áp (Relief Valve)

Van giảm áp chủ yếu là một van an toàn được sử dụng để kiểm soát hoặc giới hạn áp suất trong hệ thống, ngăn chặn sự cố thiết bị, nổ hoặc cháy do áp suất quá cao. Van hoạt động thông qua một lò xo hoặc thiết bị điều chỉnh áp suất bên trong van để kiểm soát việc mở và đóng. Van an toàn này tự động mở ở một giá trị áp suất đã đặt để xả áp suất dư thừa. Van giảm áp rất quan trọng trong nhiều ứng dụng công nghiệp, đặc biệt là trong các hoạt động có áp suất cao, đảm bảo an toàn cho ngành công nghiệp.

Van giảm áp được thiết kế với áp suất đã được cài đặt sẵn mà nó sẽ tự động mở khi áp suất hệ thống đạt đến một mức nhất định. Cài đặt này thường được điều khiển bởi một lò xo van hoặc các yếu tố cơ học khác như trọng lượng hoặc van điều khiển.

Sơ đồ cho thấy một van giảm áp hoạt động bằng lò xo. Khi áp suất hệ thống vượt quá ngưỡng đã đặt, áp suất tăng lên sẽ đẩy lõi van, nén lò xo và mở van. Điều này xả áp suất hoặc chất lỏng dư thừa, giảm áp suất trong hệ thống. Khi áp suất trở lại mức an toàn, lò xo sẽ đẩy lõi van trở lại vị trí ban đầu, đóng van lại.

d. Van Chặn (Gate Valve)

Van chặn sử dụng một cánh van di động để ngăn chặn hoặc cho phép dòng chảy, mà không điều chỉnh lưu lượng. Chúng có trở kháng dòng chảy thấp khi được mở hoàn toàn và yêu cầu nỗ lực tối thiểu để vận hành. Tuy nhiên, van chặn cần thời gian lâu hơn để mở hoặc đóng hoàn toàn do khoảng cách di chuyển của cánh van.

[17]

| Ưu điểm |

Nhược điểm |

| 1. Khả năng đóng ngắt chất lỏng xuất sắc. |

1. Chênh lệch áp suất cao có thể gây ra hiện tượng búa nước. |

| 2. Gần như không có kháng dòng chảy khi mở hoàn toàn. |

2. Thời gian mở hoặc đóng lâu. |

| 3. Phù hợp với nhiều loại chất lỏng, bao gồm chất lỏng, khí và hơi nước. |

3. Kích thước lớn, cần nhiều không gian. |

| 4. Chịu được áp suất và nhiệt độ cao. |

|

[18]

Van Chặn có nhiều loại khác nhau, thường có cấu trúc đơn giản mà không yêu cầu lắp đặt đầu vào hoặc đầu ra cụ thể. Như được thể hiện, chúng có một thanh van nổi lên được điều khiển bằng tay quay hoặc động cơ, nâng cánh van lên để mở đường dẫn dòng chảy.

Van chặn phù hợp cho các đường ống có đường kính lớn. Tuy nhiên, do có thể xảy ra các khe hở hoặc mài mòn giữa van và bề mặt niêm phong, một chút rò rỉ có thể xảy ra ngay cả khi van đã được đóng hoàn toàn. Các biện pháp bổ sung có thể cần thiết trong các ứng dụng yêu cầu niêm phong chất lỏng nghiêm ngặt.

Van quay góc phải hoạt động với một chuyển động xoay 90 độ, di chuyển lõi van theo chiều ngang hoặc chiều dọc để mở hoặc đóng đường dẫn dòng chảy. Những van này lý tưởng cho các ứng dụng yêu cầu vận hành nhanh chóng, thường được sử dụng trong các hệ thống điều khiển từ xa và tự động hóa.

Các loại van quay góc phải phổ biến bao gồm van điện từ và van khí nén. Chúng cung cấp sự tiện lợi và hiệu quả trong việc kiểm soát dòng chảy trong các ứng dụng công nghiệp khác nhau.

a. Van Điện Từ (Solenoid Valve)

Van điện từ sử dụng dòng điện trong một cuộn dây để tạo ra một trường điện từ, từ đó điều khiển hoạt động của van. Chúng cho phép điều khiển tự động và từ xa, khiến chúng trở thành lựa chọn lý tưởng cho các ứng dụng như điều khiển bật-tắt, hệ thống thử nghiệm và kiểm soát quy trình.

Van điện từ cũng được sử dụng trong các kích thủy lực và xi lanh thủy lực của xe tải, cung cấp sự chính xác và hiệu quả trong việc điều chỉnh dòng chảy chất lỏng trong các ứng dụng công nghiệp.

[19][20]

| Ưu điểm |

Nhược điểm |

| 1. Điều khiển từ xa và nhanh chóng, lý tưởng cho tự động hóa. |

1. Chỉ sử dụng cho môi trường sạch, không dùng cho chất lỏng nhớt hoặc có hạt. |

| 2. Nhỏ gọn, tiết kiệm không gian và dễ lắp đặt. |

2. Khả năng chịu áp suất thấp. |

| 3. Tiêu thụ điện năng thấp. |

3. Cần nguồn điện ổn định; không hoạt động khi mất điện. |

| 4. Kiểm soát chính xác lưu lượng và hướng dòng chảy. |

4. Cần bảo trì định kỳ cho gioăng và cuộn dây. |

Trong một van điện từ Thường Đóng (NC), van sẽ ở trạng thái đóng khi cuộn dây solenoid không được cấp điện. Bên trong van điện từ NC, có một cần điều khiển được bao quanh bởi cuộn solenoid. Một lò xo kết nối cần điều khiển với một pít-tông. Khi không có điện, pít-tông sẽ chặn lối đi.

Khi có dòng điện được cấp, một trường điện từ được tạo ra bên trong van solenoid, kéo pít-tông lên và mở lối đi, cho phép chất lỏng chảy qua. Khi dòng điện được tắt, pít-tông trở lại vị trí ban đầu, chặn dòng chảy chất lỏng.

[21]

b. Van Khí Nén (Pneumatic Valve)

Van khí nén, hay còn gọi là van điều khiển bằng không khí, sử dụng áp suất khí để điều khiển dòng chảy của chất lỏng, phù hợp với các điều kiện áp suất và nhiệt độ cao. Chúng được sử dụng trong ngành năng lượng để kiểm soát dầu, khí và nước, trong ngành hóa chất cho các bể phản ứng và bồn chứa, cũng như trong các thiết bị y tế như máy thở và hệ thống cung cấp khí.

Nguyên tắc hoạt động của van khí nén rất đơn giản: van mở ra khi không có khí và đóng lại khi có khí.

[22]

| Ưu điểm |

Nhược điểm |

| 1. Độ an toàn cao, hoạt động tốt trong điều kiện khắc nghiệt. |

1. Cần hệ thống khí nén, chi phí lắp đặt ban đầu cao. |

| 2. Đóng/mở nhanh, phù hợp cho các ứng dụng yêu cầu phản ứng nhanh. |

2. Cần thiết bị lọc và sấy để bảo vệ các bộ phận. |

| 3. Lực mạnh, lý tưởng cho van lớn và hệ thống áp suất cao. |

3. Độ chính xác kiểm soát hạn chế, không lý tưởng cho điều chỉnh lưu lượng chính xác. |

| 4. Thiết kế đơn giản, bền bỉ, tốt cho việc sử dụng thường xuyên. |

4. Có thể phát ra tiếng ồn khi xả khí. |

Van Khí Nén bao gồm hai phần chính: thiết bị cơ khí ở dưới và thiết bị khí nén ở trên. Bên trong thiết bị cơ khí là đĩa van, di chuyển lên và xuống để mở hoặc đóng van, tương tự như van chặn (van bi). Van được bao phủ bởi một nắp van, có thể mở ra để bảo trì bên trong. Thiết bị cơ khí được kết nối với thiết bị phía trên qua một trục thẳng đứng có kim chỉ báo cho biết van đang mở hay đóng.

Thiết bị phía trên chứa một bộ truyền động khí nén. Khi khí được bơm vào qua cổng, áp suất khí sẽ nén màng và lò xo, đẩy lõi van xuống để đóng lối đi, ngăn chặn dòng chảy chất lỏng. Ngược lại, khi khí được xả ra, lò xo nở ra, lõi van di chuyển lên và lối đi mở, cho phép chất lỏng chảy qua.

[23][24]