Overview

- When kidneys fail, dialysis is needed to replace their function, removing waste and excess water.

- Hemodialysis involves filtering the patient's blood outside the body through an artificial membrane in a dialysis machine, then returning the cleaned blood.

- Peritoneal dialysis uses the patient's peritoneum, a natural membrane in the abdominal cavity, to filter waste by infusing dialysis fluid.

- Water treatment is crucial for dialysis fluid safety. Common chemicals in tap water, such as aluminum, chloramines, fluoride, copper, zinc, and endotoxins, pose risks for kidney patients.

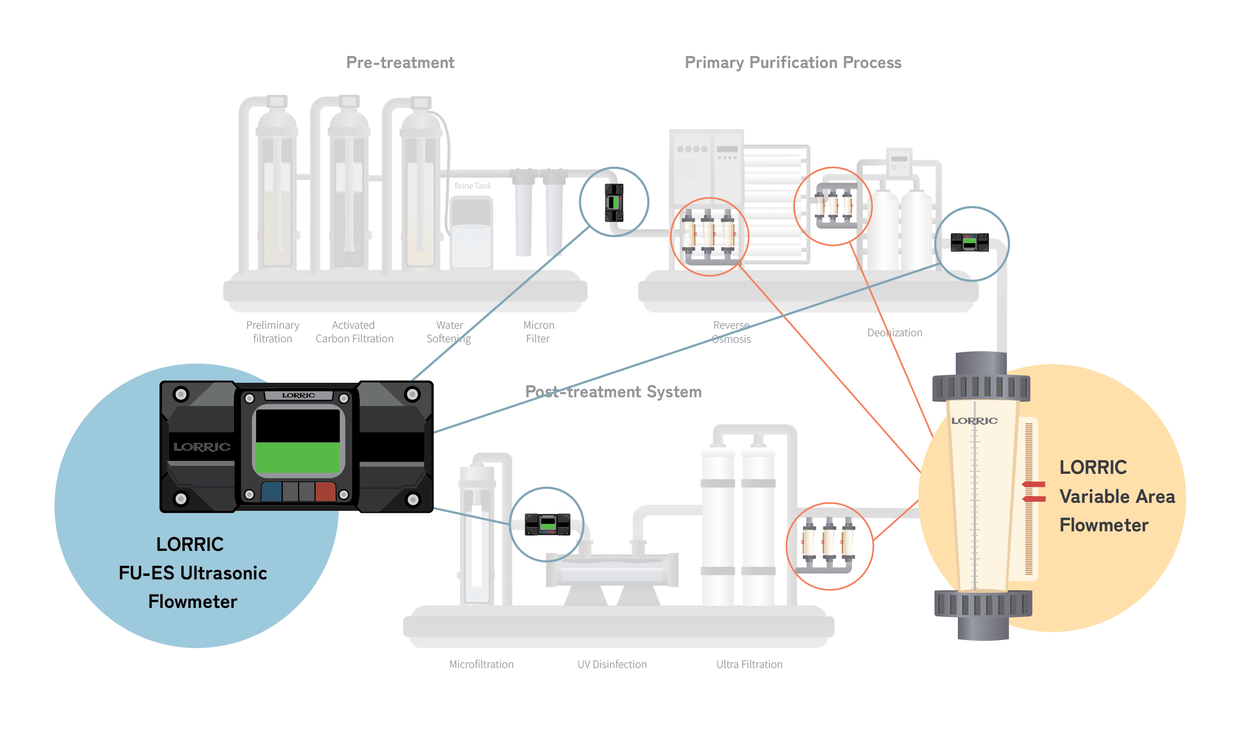

- The innovative LORRIC ultrasonic flowmeter helps water treatment equipment manufacturers automate data collection and transmission.

1. Can you get off dialysis once you start? How to Prevent

Whether dialysis is needed for life depends on the severity of the kidney disease. In cases of acute kidney injury, patients may require short-term dialysis, which can be discontinued if kidney function recovers. However, patients with chronic kidney failure often need long-term or lifelong dialysis, unless they can receive a kidney transplant. Transplantation requires a suitable donor and the patient must meet specific criteria for the surgery.

Many patients are diagnosed with chronic conditions, such as hypertension, high blood sugar, and high cholesterol, which can lead to chronic kidney disease, a year before starting dialysis. To prevent kidney disease, focus on managing these conditions by maintaining a healthy weight, exercising regularly, and undergoing regular health check-ups, including blood tests (for creatinine and blood urea nitrogen) and urine tests (for protein). It's also important to monitor for symptoms like leg swelling, foamy urine, or blood in the urine.

2. How Does Dialysis Work? What is Hemodialysis

Dialysis, commonly referred to as "renal dialysis," includes hemodialysis and peritoneal dialysis. Hemodialysis involves an external circuit to filter blood, while peritoneal dialysis uses the body's peritoneum as a filter. Most patients in Taiwan opt for hemodialysis.。

1) Hemodialysis

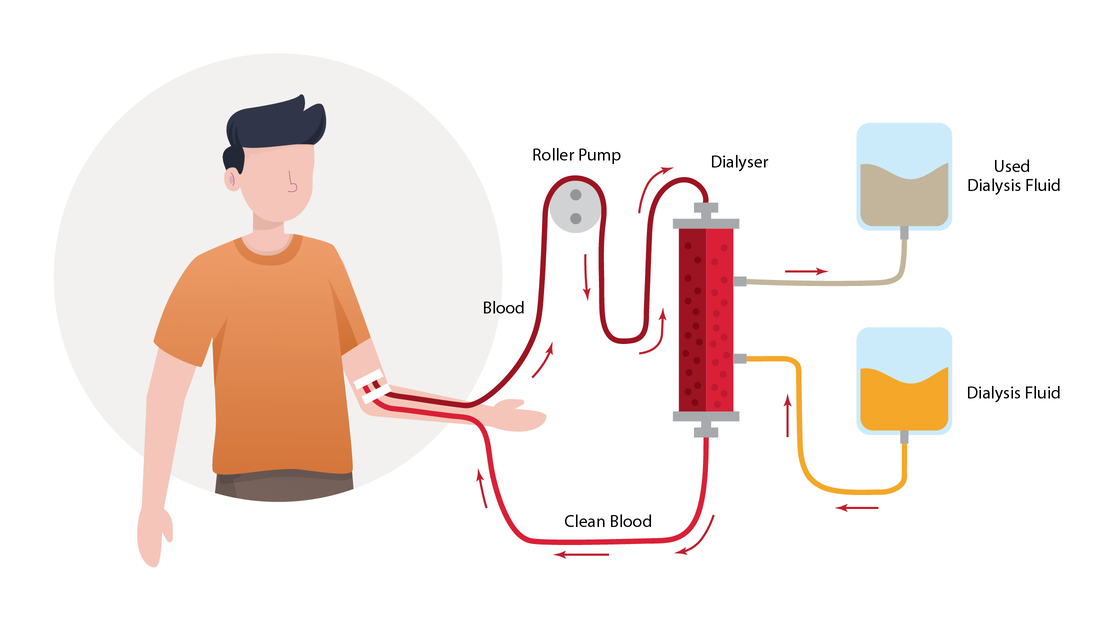

Hemodialysis involves drawing the patient's blood out of the body, filtering it, and returning it. The blood is passed through a dialysis machine, also known as an artificial kidney, where it is filtered through a semipermeable membrane to remove waste and excess fluids. This treatment requires visiting a dialysis center, typically 2-3 times a week, with each session lasting 4-5 hours. Since hemodialysis intermittently removes waste and fluids, patients must follow a strict diet, limiting intake of potassium, phosphorus, salt, and fluids, and ensuring appropriate protein intake (around 1.0-1.2g/kg). Diabetic patients may also need to limit sugar intake.

[1]

2) Peritoneal Dialysis

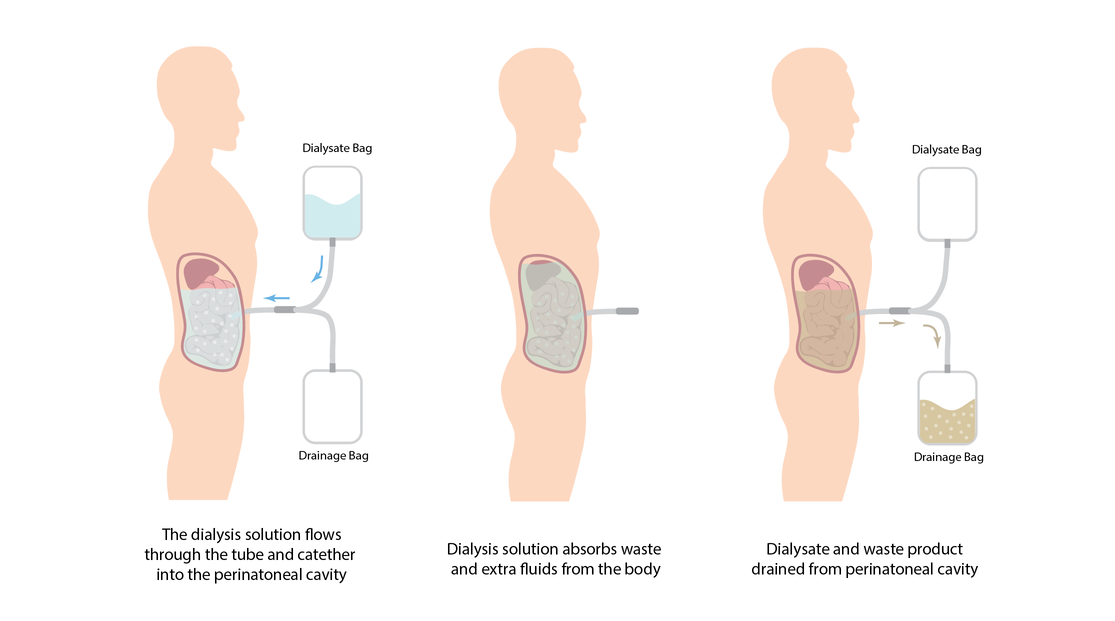

Peritoneal dialysis (PD) utilizes the natural semipermeable membrane of the patient's peritoneum to filter blood within the body. A catheter is surgically inserted into the abdominal cavity, serving as a channel for dialysis fluid. Patients use a Continuous Ambulatory Peritoneal Dialysis (CAPD) machine at home. During treatment, dialysis fluid is infused into the abdominal cavity via the catheter, where it exchanges waste and electrolytes with the blood across the peritoneal membrane, then the fluid is drained out.

Peritoneal dialysis can be performed at home, with patients changing the dialysis fluid 4-5 times daily, each session lasting around 4 hours. There's also Automated Peritoneal Dialysis (APD), which operates overnight while the patient sleeps. The dietary restrictions are less stringent compared to hemodialysis, but patients must handle the procedure carefully and maintain the catheter to prevent displacement or infection.

[2]

3) Water Treatment in Dialysis Equipment

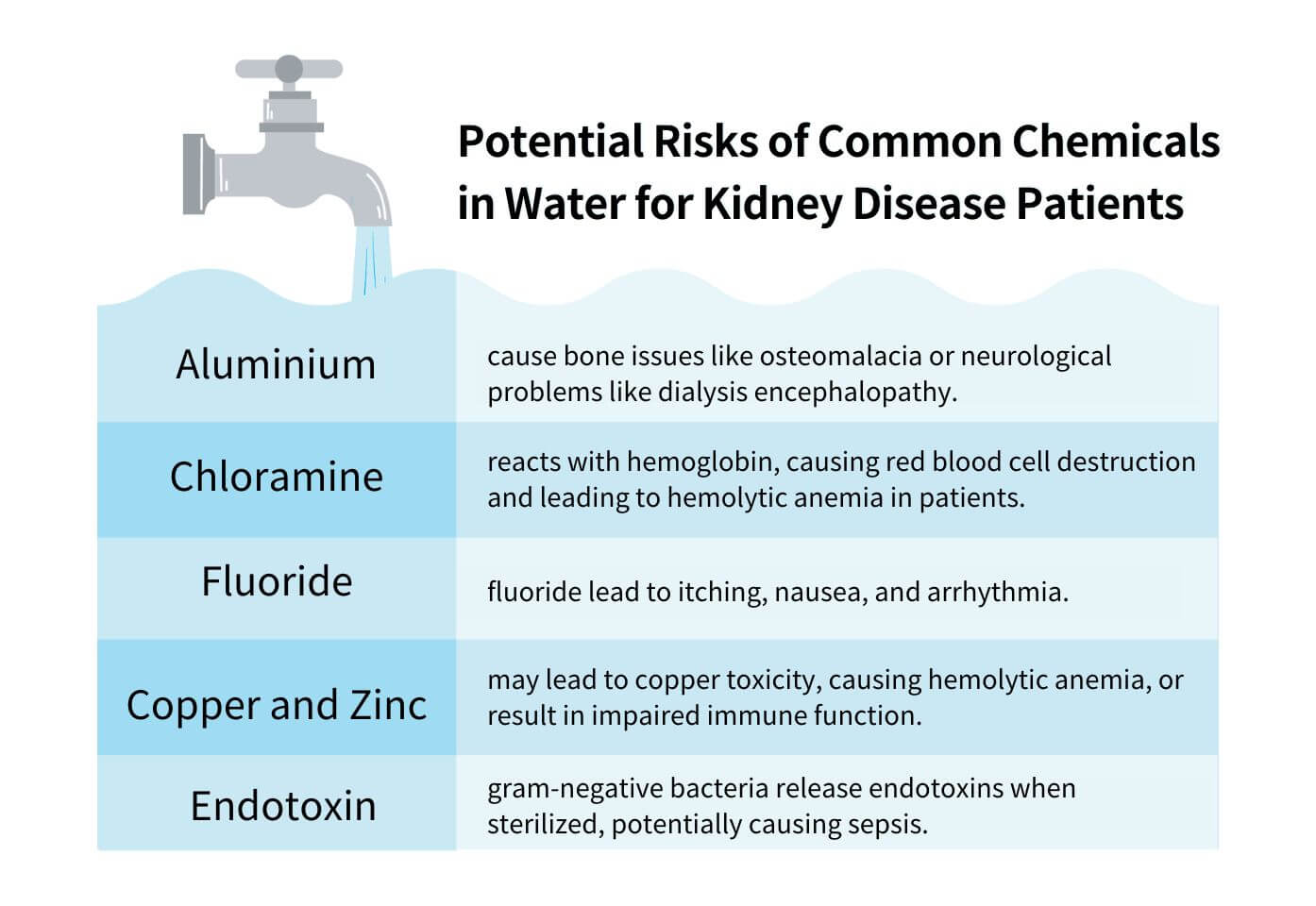

In hemodialysis treatment, the dialysis fluid directly interacts with the patient's blood, making water quality crucial. Hospitals enforce stringent water quality standards to ensure patient safety. Common chemicals in tap water, such as aluminum, chloramines, fluoride, copper, and zinc, can pose significant risks to kidney patients if not properly filtered out. Understanding these risks highlights the critical role of water treatment in dialysis equipment, ensuring that the water used is free from harmful contaminants and safe for medical use.

Aluminum

Tap water systems often contain aluminum, used as a coagulant to remove suspended particles. While healthy kidneys can filter excess aluminum, impaired kidneys cannot, leading to aluminum accumulation. This can cause osteomalacia, a bone-softening condition, and dialysis encephalopathy, a neurological disorder.

Chloramine

Chloramine is a disinfectant in drinking water, effective in long distribution systems. However, if not removed during dialysis, chloramine can pass through the dialysis membrane into the blood, reacting with hemoglobin and causing hemolytic anemia.

Fluoride

Fluoride, known for strengthening tooth enamel, is added to drinking water for dental health. In kidney patients, however, excess fluoride cannot be effectively filtered, leading to symptoms like itching, nausea, and arrhythmia.

Copper and Zinc

Copper and zinc may leach from water pipes and fittings into the supply. While healthy kidneys regulate these metals, impaired kidneys may lead to copper toxicity, hemolytic anemia, or compromised immune function.

Endotoxin

Tap water can contain microorganisms, including gram-negative bacteria. While chloramine in municipal systems kills bacteria, the bacteria's dead cell walls can release endotoxins. Normally processed by the liver and immune system, these endotoxins can cause sepsis if not filtered during dialysis.

4. What is Ultrapure Water? How Is It Made?

Understanding the risks posed by common substances in tap water to patients with impaired kidneys highlights the importance of water treatment in hemodialysis. To mitigate these risks, dialysis centers produce "ultrapure dialysis fluid" using stringent water purity standards set by the Association for the Advancement of Medical Instrumentation (AAMI) and the International Organization for Standardization (ISO). These standards mandate that the microbial count in the water must be less than 100 CFU/mL, and endotoxin levels should be below 0.25 EU/mL. This ultrapure water is crucial for safely cleaning patients' blood during dialysis, minimizing the risk of introducing harmful contaminants.

[3]

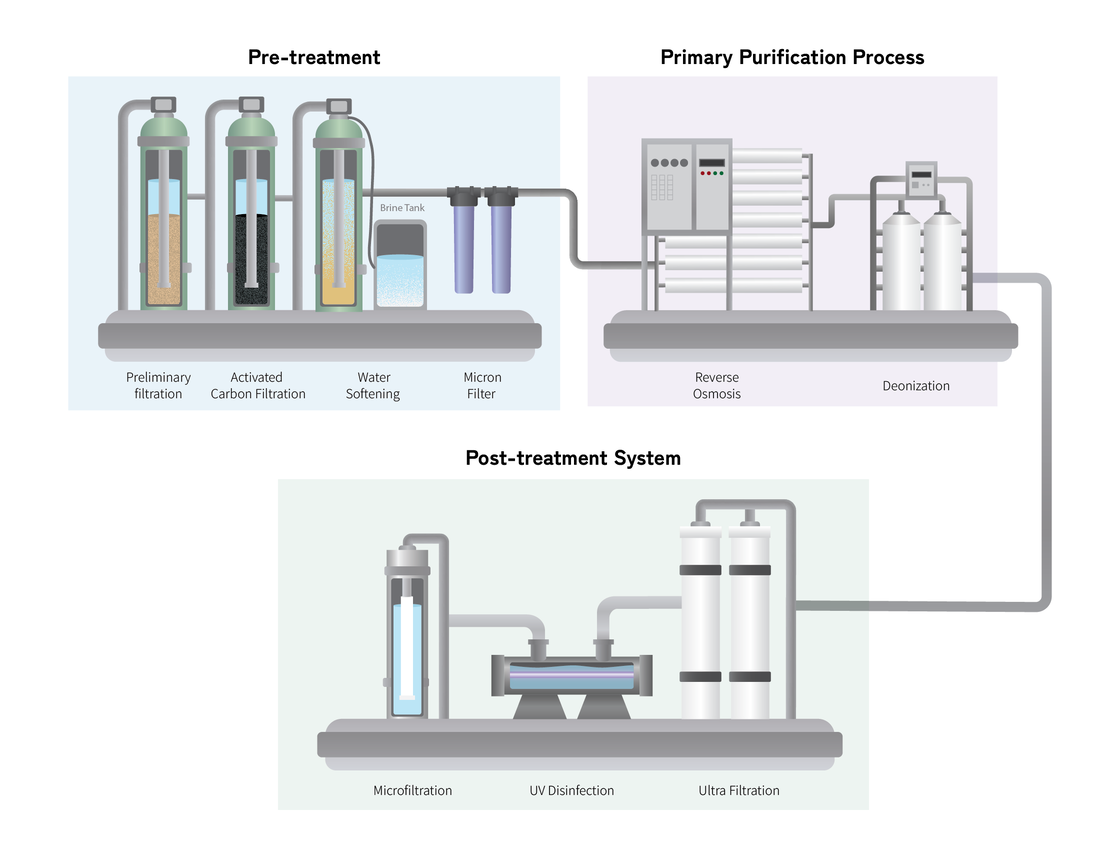

1) Pre-treatment

The primary goal of pre-treatment is to filter impurities and protect the main treatment system.

1. Preliminary filtration - Removes large particles, sediments, and suspended solids.

2. Activated Carbon Filtration - Water passes through a filter containing granular activated carbon (GAC), which adsorbs organic contaminants, residual chlorine, and chloramines.

3. Water Softening (Water Softening) - Uses ion exchange resins to soften water by exchanging sodium ions for calcium and magnesium ions, preventing scale formation.

4. Micron Filters - Filters out impurities down to 1 micron.

2) Primary purification process

This stage focuses on purifying the water to a high degree.

5. Reverse Osmosis, RO - Uses osmotic pressure to drive water through a semipermeable membrane, removing over 90% of contaminants, including dissolved salts, metal ions, bacteria, and endotoxins.

6. Deionization, DI - Employs mixed-bed ion exchange resins to remove remaining cations and anions, further eliminating ionic contaminants.

3) Post-treatment System

This stage emphasizes sterilization and filtration to ensure water purity.

7. Ultrafiltration, UF - Removes bacteria that may grow in the DI process due to its moist environment.

8. Ultraviolet Disinfection, UV - Uses UV-C light to disrupt the DNA and RNA of microorganisms, effectively sterilizing the water.

9. Microfiltration - The final stage employs a 0.2-micron filter to ensure the highest water purity, suitable for dialysis use.

[4][5][6]

5. Ultrasonic Flow Meters and Automated Data Collection

During our visit to Lee Med Tech Co., Ltd. in Nam Phong, Thailand, we explored how ultrasonic flow meters and other sensors automate data collection and transmission in water treatment systems. Lee Med Tech Co., Ltd. provides water treatment equipment and cloud data services to Fort Kawila Hospital's hemodialysis center.

The collected data is transmitted to a cloud platform for real-time analysis and maintenance, enhancing the reliability and safety of the water treatment processes. For more details on the role of sensors in medical technology and ultra-pure water systems, read the article "

Sensors in Medical Technology and Ultra-Pure Water Systems."

At the site, we installed LORRIC FU-ES ultrasonic flow meters on the piping of the reverse osmosis (RO) equipment. These flow meters are equipped with RS485 communication protocol, which allows them to transmit detected flow information to a Programmable Logic Controller (PLC). The PLC processes the input signals based on pre-programmed control instructions, overseeing and automating mechanical and electrical systems.

The data collected by the PLC is transmitted via MQTT protocol using TCP/IP to a designated cloud network. This setup enables the hospital to collect and organize data on water usage for dialysis. By logging into the cloud database, staff can access real-time water consumption and related data from any computer or mobile device, facilitating efficient monitoring and management.

[7][8]

Why Choose "LORRIC FU-ES Ultrasonic Flow Meter"?

Non-Intrusive Installation: The FU-ES ultrasonic flow meter features a clamp-on design, which allows for installation without cutting pipes or shutting down the system. This ensures that the equipment can be installed without interrupting operations.

Multiple Communication Protocols: The FU-ES supports a range of communication protocols, offering flexibility based on specific needs. Options include 16-bit 4-20mA analog output, Modbus RTU RS485, and two-wire optical coupler switch signals (compatible with NPN/PNP).

EchoSense Technology: This advanced software technology automatically detects data such as pipe diameter, pipe specifications, and the detection environment. The meter can be operational right after installation without requiring complex parameter settings. During our visit to Lee Med Tech, the FU-ES was successfully installed on PVC, stainless steel 316, and PVDF pipes, demonstrating reliable performance across different materials.

With the FU-ES's diverse communication support and easy installation design, LORRIC has enabled equipment manufacturers to achieve automated flow data collection, providing dialysis centers with a cloud database. We look forward to the brand's continued support in advancing applications in the equipment and medical industries.

Learn more about :

LORRIC FU-ES Ultrasonic Flow Meter