LORRIC provides several different kinds of nozzles, for the usage of different industries, and to accommodate different manufacturing processes and the problems they face. The following seven points serve as a reference guide in choosing the correct nozzle for your needs.

1. Spray Pattern

∙ The spray pattern, the most important distinguishing characteristic of any nozzle, indicates in what shape liquid or gas is being transmitted through the nozzle and onto a target vertical surface or object. Although the spray shape is being dictated and thus changed according to spray pressure, what actually changes is the size and proportion of the shape, while the shape itself persists.

∙ Since various industries and manufacturing processes have different requirements, LORRIC provides several different nozzle spray shapes for our clients to choose from. While clients often choose themselves which nozzles would fit their needs, you are more than welcome to contact us directly regarding any hesitation or question – our advisors would inquire about your needs and provide suggestions.

∙ Nozzle manufacturers name and classify their products differently. While being generally similar, these nozzles still have minute details that differ. For that you are welcome to contact our advisors with a specific nozzle manufacturer’s name and product number, and we would happily offer an equally fitting suggestion from our range of products.

∙ The following is an introduction to our nozzle spray shapes, hover over the links for more details.

- Flat fan type

- Cone type (aka umbrella shape and full cone shape)

- Hollow cone type (aka ring shape and donuts shape)

- Spiral type (aka mosquito coils shape, concentric circles shape, semisolid shape)

- Columnar type (aka straight line shape, point shape, and straight shape)

- Liquid mixing spray, which is a specific spray type as there is not a spray shape when mixing liquid.

2. Fluid Type

The three most commonly used fluids are:

- Unmixed liquid

- Unmixed gas

- A combination of liquid and gas

3. Material

In order to accommodate to various needs and uses, LORRIC offers several types of nozzles, made from different materials under different machining processes, and with different elasticity and other properties. When choosing which materials your wanted nozzle should be made of, refer to the following guiding points:

- The temperature of the fluids and the environment

- Whether fluid contains solid bodies or not

- Whether chemical reagents are present or not

- If the nozzles’ purpose is cleaning, do not choose ones with rubber seals

- Whether mechanical strength is needed or not

- Whether industry regulations demand specific materials to be used: for example the food industry often demands stainless steel products etc

| Materials |

Introduction |

| BRASS |

Brass is the basic material for metal nozzles, it generally is lacking in wear-resistance and in chemical tolerance. |

| AISI303 |

AISI 303 is a basic form of stainless steel, with better wear-resistance and chemical tolerance than brass. |

| AISI316 |

AISI 316 is considered a better form of stainless steel, with even better wear-resistance and chemical tolerance than ASIS 303, and also has a bright metallic gloss appearance to it. |

| Hastelloy C22 |

Hastelloy C22 is an Inconel alloy with great chemical tolerance that fits high temperature environments with a high concentration of chemicals. |

| PVC |

PVC’s properties are high mechanical strength, while temperature resistance is lacking. |

| UHMWPE |

While having average temperature and chemical resistance. UPE has outstanding wear resistance capabilities, making it applicable for long time usage with emery sandblasting machines. |

| PP |

With average temperature and chemical tolerance, PP is an entry level plastic material for nozzles. |

| PVDF |

With relatively better temperature and chemical tolerance. PVDFI’s mechanical strength is also better than PP’s. |

| Nylon |

Nylon’s distinguishing property is high wear-resistance. |

| PEEK |

Peek’s chemical tolerance properties are fantastic, while also being able to endure temperatures reaching above 200°C. With high such high rigidity and durability, it is best used in environments that require high chemical tolerance, high temperature tolerance.

|

| PTFE |

PTFE’s has the highest chemical-tolerance, as well as high temperature endurance of above 200°C. Its rigidity however is mediocre. |

4. Adaptor

∙ LORRIC provides several different adaptor types. While the most commonly used one is the male adaptor, also offered are female adaptors, flange adaptors and weld adaptors. Weld adaptors can be used regardless of whether there is a fixed segmentation or not.

∙ The nozzle’s male adaptor is generally designed as a taper thread to prevent leakage. However, for complete sealing, tape seal will also have to be used. While in other industries a parallel thread is often used, in the nozzles industry a taper thread is more fitting. Normally there are two types of taper thread standards: one is the NPT, mostly common in North America, and the second is the BSPT (aka PT), mostly in usage in other parts of the world.

∙ Generally speaking, for nozzles designed for larger flow rates, a larger adaptor is also needed. Different adaptors will also provide different flow rates and spray angle choices. For further details, please refer to our product page for explanations.

5. Pressure

∙ Regarding nozzle performance, clearly the most important factor would be the spray pressure. Even when using the exact same nozzle, under different pressure levels performance would differ: spray shape, flowrate, spray angle, spray distribution, particle size etc. Therefore, any nozzle at the design level has a “standard operating pressure”, used to measure the nozzle’s performance. As an example, a nozzle that operates with a 110° spray angle while being under a 3kg/cm^2 pressure, will provide a spray angle of below 100° when operating under a 1kg/cm^2 pressure. Therefore when attempting to choose the correct nozzle, confirming the nozzle’s pressure beforehand would save precious operating time.

∙ The majority of nozzles do not have an automatic pressure function, and they rely on pressure provided by the installation’s pump, or the factory’s pipeline. When attempting to confirm the pressure to be provided for nozzles, it’s best to prioritize checking the pressure gauge nearest to the nozzle, as the further the distance is between the pressure gauge and the nozzle, the more other factors come into play in influencing the reading.

∙ Different countries and industries use different measuring units to measure pressure. The following table introduces the most commonly used measuring units.

| kg/cm² |

The most common unit for measuring pressure as well as being the legal standard for measurement in Taiwan.

|

| Bar |

1 Bar = 1.02 kg/cm² |

| MPa |

The most common unit for measuring pressure in Japan

MPa = 10.2 kg/cm² |

PSI

(Pound/inch²) |

The most common unit for measuring pressure in the USA

1 psi = 0.07 kg/cm² |

6. Flow Rate

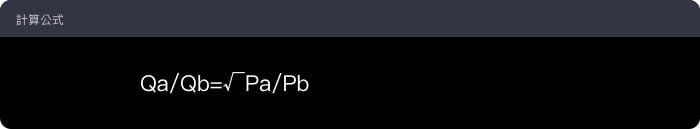

The definition of flow rate is the volume of liquid or gas sprayed by the nozzle during a certain period of time under stable pressure. Generally speaking, in regards to the exact same nozzle, the greater the pressure, the greater the flowrate. Flowrate and pressure though do not have linear relationship, but are approximately proportional to the square root of the given pressure.

Different countries and industries use different measuring units to measure flowrate. The following table introduces the most commonly used measuring units.

| LPM ( l/min ) |

The most commonly used flowrate measuring unit worldwide. |

| GPM ( gal/min) |

The most commonly used flowrate measuring unit in the USA. |

7. Spray Angle

∙ The definition of spray angle is the angle that emerges after having liquid or gas sprayed out of the nozzle. The further away the fluids are sprayed from the nozzle, the more they are influenced by earth’s gravitational force and other environmental factors, and thus the angle might increase or decrease in size. The spray angle is thus only an assessment tool, however an important one, which also demands to take into consideration the distance between the equipment used and the nozzle. Whether your spray system uses a range of meters or millimeters, you are welcome to contact us in order to ensure optimal nozzle performance according to your needs.

∙ Needed to be taken into consideration as well is the fact that in different spray directions, the variation of the spray angle according to distance will also change. Generally speaking, when spraying from top to bottom, the spray angle will become smaller, and when spraying from bottom to top, the spray angle will become larger, what will need to be taken into consideration when designing spray equipment.

∙ We at LORRIC guarantee a spray angle tolerance of ± 5° when operating under standard pressure, what also can be taken into consideration when designing your equipment’s spraying distance.

[1]