Flow meter installation methods vary based on site conditions, operating environment, fluid type, and pipeline material, including:

1、Inline

Cutting the piping to install the flow meter between cuts, a common and cost-effective method.

2、Insertion

Creating a hole in the pipeline wall and securely inserting the flow meter.

3、Clamp-on

For situations where cutting the pipe would be too costly, such as operational lines that cannot be shut down, large diameters, or where cutting expenses are prohibitive, a clamp-on flow meter is installed outside the pipe without needing to cut.

Following inline installation, which involves cutting the pipe and installing the flow meter in the gap, fittings are used to mount the flow meter onto the pipeline. Users can select suitable flow meter fittings based on pipeline diameter, material, and fluid characteristics. Common materials for plastic pipelines include PP, PVDF, SS (Stainless Steel), and UPVC, with only UPVC allowing for adhesive joint connections.

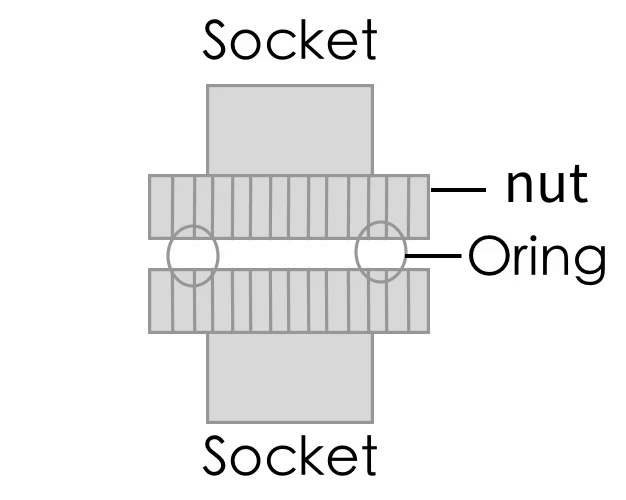

1、Union + Other Fittings

Common method using a fitting (threaded or other types), an O-ring, and a nut to secure and seal the connection between the pipeline and flow meter.

All other fittings mentioned in this article can also serve as union fittings, making the union the most versatile and flexible piping structure.

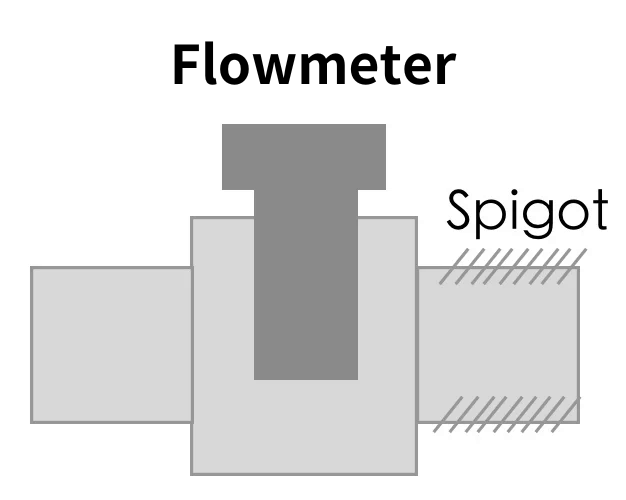

2、Spigot

Uniformly sized to match the outer diameter of the target pipeline, allowing the use of common pipeline components for installation. Suitable for large-sized flow meters.

3、Socket

Common for small pipelines, where the corresponding pipe fits inside the socket fitting. The fixing method depends on the material, with UPVC often glued and PP and PVDF using heat socket welding.

4、Heat Fusion

Suitable for PP and PVDF materials, involves heating the ends of pipes and fusing them together.

5、Threaded Connections:

Male Threaded and Female Thread utilizes standard NPT or PT threads for fittings.

6、Metal Welding

Joins pipes with similar outer diameters using welding methods for the highest structural strength.

7、Flanges and Flange Locking

Using several bolts to clamp two flange structures together, often with a sealing gasket for integrity. This method is strong and can handle high pressure, making it common for large-diameter pipelines. However, it's less common in smaller pipes due to the complexity of disassembly.

8、Sanitary Clamp Fittings:

Common in stainless steel pipelines, a simplified version of flanges with a clamp locking mechanism for quick assembly and disassembly.