1. What is "Spray Angle"?

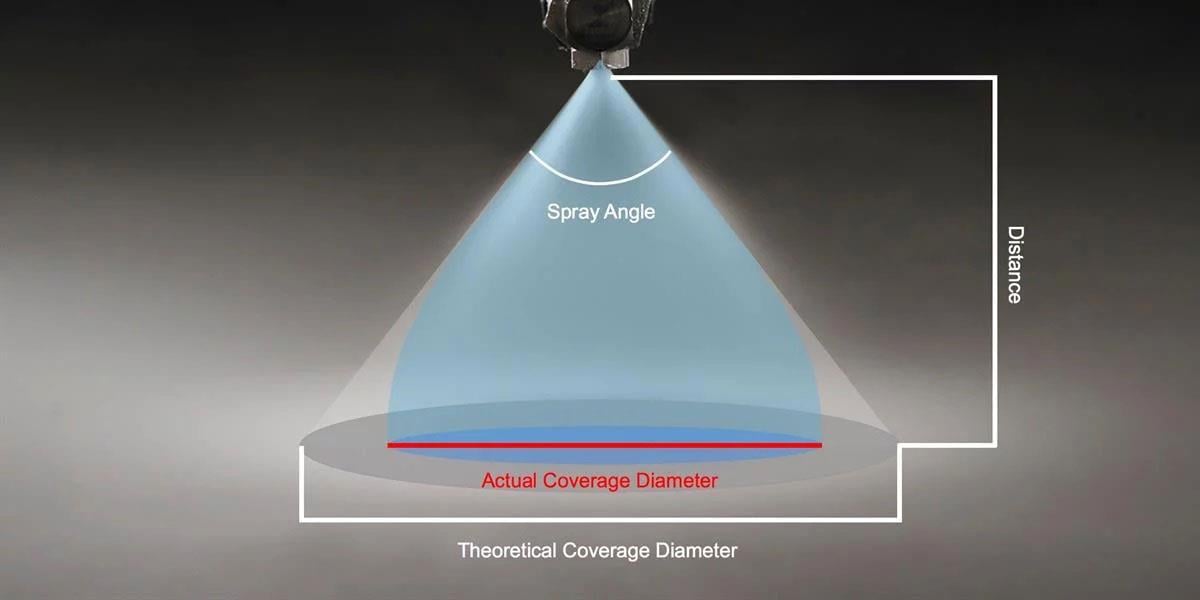

When we refer to the spray angle (spray cone angle), we are talking about the angle formed between the centerline of the nozzle outlet and the edges of the spray on both sides. After the liquid exits the nozzle, it cannot continue in a tangential direction due to the effects of gravitational acceleration and air resistance. As a result, the the "actual spray coverage" may be smaller than the "theoretical spray coverage"

2. How to Calculate the Spray Angle?

Currently, there is no internationally standardized method for measuring spray angles, but common measurement techniques include protractor-based measurement and optical measurement.

- Traditional Protractor Measurement Method:

The nozzle is fixed and kept in a horizontal position. A protractor is used to align with the edges of the spray emitted from the nozzle center, and the spray angle is read. This method is low-cost but may be affected by human error.

- Optical Measurement Method:

Using a stable light source, a high-resolution camera captures the shape of the spray. Specialized computer software, such as CAD or image processing software, is then used to calculate the spray angle. This method is highly accurate but requires expensive software and professional expertise. LORRIC employs the optical measurement method to ensure the quality of every nozzle before shipment.

3. How to Calculate the Theoretical Spray Coverage Area?

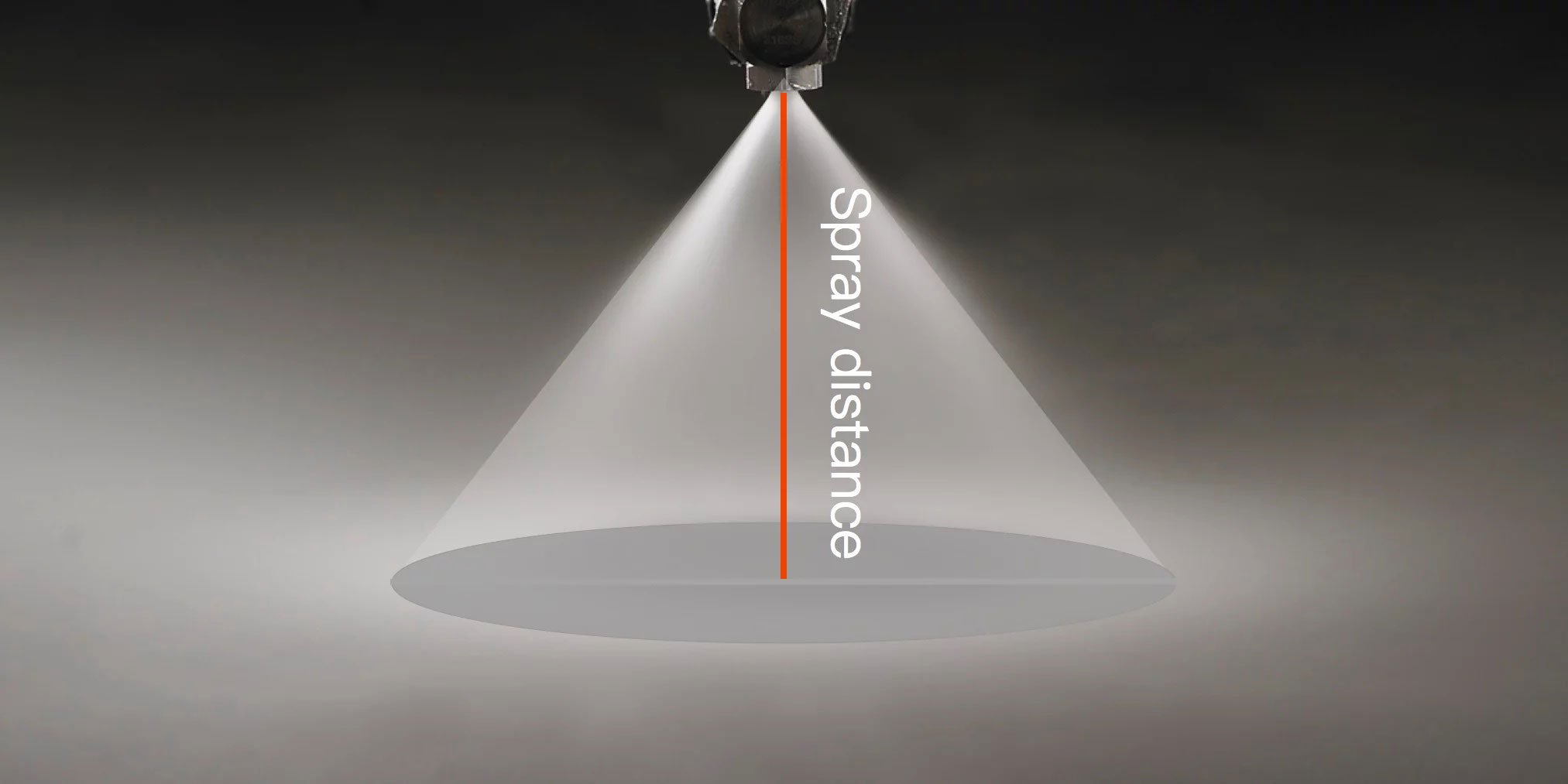

The spray angle is influenced by both the size of the nozzle’s spray orifice and the distance between the nozzle and the target surface. This relationship also determines the spray coverage area and the density of the liquid relative to the covered area.

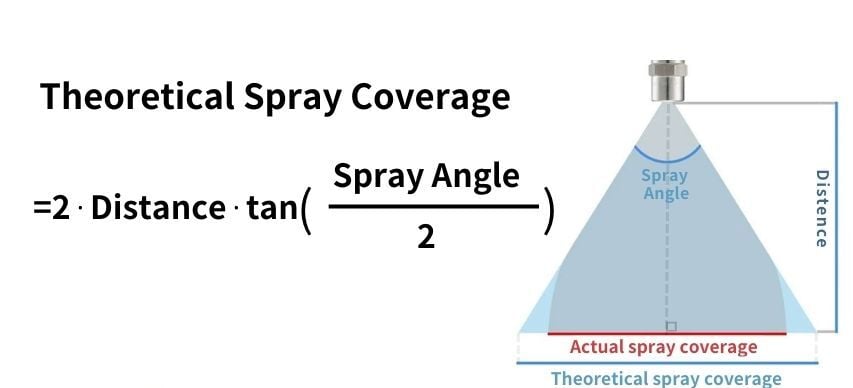

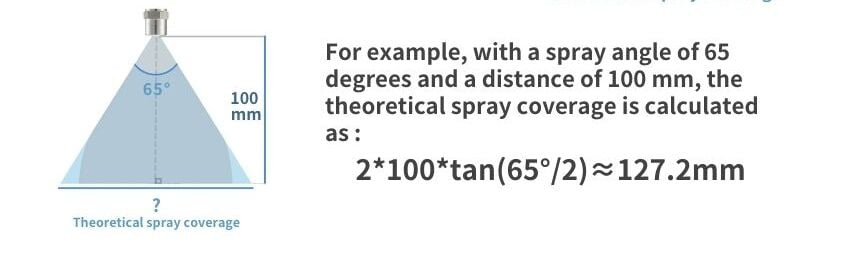

To calculate the theoretical spray coverage area, we need to know both the spray angle and the distance between the nozzle outlet and the object. The formula for calculating the spray coverage area is as follows:

Theoretical Spray Coverage =2⋅Distance⋅tan(Spray Angle/2)

In summary, the relationship between angle, coverage area, and distance is: generally, the larger the spray angle, the wider the coverage area, but the spray distance will be relatively shorter. Conversely, a smaller spray angle results in a narrower coverage area but allows the spray to reach farther distances.

4. Spray Angle and Coverage Area Reference Table

LORRIC provides a reference table showing the calculated spray angles and corresponding coverage areas based on the formula. It is important to note that due to factors like gravity and aerodynamic drift, the spray angle can only be maintained over a limited distance—typically up to 300 mm from the nozzle outlet.

Unit: inch

Spray Angle (°)

|

Theoretical Spray Coverage (Unit:inch) |

| 40 |

55 |

60 |

65 |

70 |

75 |

80 |

90 |

100 |

120 |

170 |

|

Distance

(inch)

|

1.0

|

0.7 |

1.0 |

1.2 |

1.3 |

1.4 |

1.5 |

1.7 |

2.0 |

2.4 |

3.5 |

23 |

|

1.5

|

1.1 |

1.6 |

1.7 |

1.9 |

2.1 |

2.3 |

2.5 |

3.0 |

3.6 |

5.2 |

34 |

|

2.0

|

1.5 |

2.1 |

2.3 |

2.5 |

2.5 |

2.8 |

4.2 |

4.0 |

6.0 |

8.7 |

57 |

|

2.5

|

1.8 |

2.6 |

2.9 |

3.2 |

3.5 |

3.8 |

5.0 |

5.0 |

7.2 |

10 |

69 |

|

3.0

|

2.2 |

3.1 |

3.5 |

3.8 |

4.2 |

4.6 |

5.0 |

6.0 |

7.2 |

10 |

69 |

|

3.5

|

2.5 |

3.6 |

4.0 |

4.5 |

4.9 |

5.4 |

5.9 |

7.0 |

8.3 |

12 |

80 |

|

4.0

|

2.9 |

4.2 |

4.6 |

5.1 |

5.6 |

6 |

6.7 |

8.0 |

10 |

14 |

91 |

|

4.5

|

3.3 |

4.7 |

5.2 |

5.7 |

6.3 |

7 |

7.6 |

9.0 |

11 |

16 |

103 |

|

5

|

3.6 |

5.2 |

5.8 |

6.4 |

7 |

8 |

8.4 |

10 |

12 |

17 |

114 |

|

6

|

4.4 |

6.2 |

6.9 |

7.6 |

8 |

9 |

10 |

12 |

14 |

21 |

137 |

|

7

|

5.1 |

7.3 |

8.1 |

8.9 |

10 |

11 |

12 |

14 |

17 |

24 |

160 |

|

8

|

5.8 |

8.3 |

9 |

10 |

11 |

12 |

13 |

16 |

19 |

28 |

183 |

|

9

|

6.6 |

9.4 |

10 |

11 |

13 |

14 |

15 |

18 |

21 |

31 |

206 |

|

10

|

7.3 |

10.4 |

12 |

13 |

14 |

15 |

17 |

20 |

24 |

35 |

229 |

|

11

|

8.0 |

11.5 |

13 |

14 |

15 |

17 |

18 |

22 |

26 |

38 |

251 |

|

12

|

8.7 |

12.5 |

14 |

15 |

17 |

18 |

20 |

24 |

29 |

42 |

274 |

|

13

|

9.5 |

12 |

15 |

18 |

20 |

22 |

23 |

26 |

31 |

45 |

297 |

|

14

|

10 |

13 |

16 |

17.8 |

19.7 |

21.8 |

24 |

28 |

33 |

48 |

320 |

|

18

|

13 |

19 |

21 |

23 |

25 |

28 |

30 |

32 |

43 |

62 |

411 |

|

20

|

15 |

21 |

23 |

25 |

28 |

31 |

34 |

36 |

48 |

69 |

457 |

|

22

|

16 |

23 |

25 |

28 |

31 |

34 |

37 |

40 |

52 |

76 |

503 |

|

24

|

17 |

25 |

28 |

31 |

34 |

37 |

40 |

44 |

57 |

83 |

549 |

|

26

|

19 |

27 |

30 |

33 |

36 |

40 |

44 |

48 |

62 |

90 |

594 |

|

28

|

20 |

29 |

32 |

36 |

39 |

43 |

47 |

52 |

67 |

97 |

640 |

|

30

|

22 |

31 |

35 |

38 |

42 |

46 |

50 |

56 |

72 |

104 |

686 |

|

32

|

23 |

33 |

37 |

41 |

45 |

49 |

54 |

60 |

76 |

111 |

732 |

|

34

|

25 |

35 |

39 |

43 |

48 |

52 |

57 |

64 |

81 |

118 |

777 |

|

36

|

26 |

37 |

42 |

46 |

50 |

55 |

60 |

60 |

86 |

125 |

823 |

Unit: mm

Spray Angle (°)

|

Theoretical Spray Coverage (Unit:mm) |

| 55 |

60 |

65 |

70 |

80 |

75 |

90 |

100 |

120 |

|

Distance

(mm)

|

30 |

31 |

35 |

38 |

42 |

50 |

46 |

60 |

72 |

104 |

| 40 |

42 |

46 |

51 |

56 |

67 |

61 |

80 |

95 |

139 |

| 50 |

52 |

58 |

64 |

70 |

84 |

77 |

100 |

119 |

173 |

| 60 |

62 |

69 |

76 |

84 |

101 |

92 |

120 |

143 |

208 |

| 70 |

73 |

81 |

89 |

98 |

117 |

107 |

140 |

167 |

242 |

| 80 |

83 |

92 |

102 |

112 |

160 |

123 |

160 |

191 |

277 |

| 90 |

94 |

104 |

115 |

126 |

180 |

138 |

180 |

215 |

312 |

| 100 |

104 |

115 |

127 |

140 |

200 |

153 |

200 |

238 |

346 |

| 110 |

115 |

127 |

140 |

154 |

220 |

169 |

220 |

262 |

381 |

| 120 |

125 |

139 |

153 |

168 |

240 |

184 |

240 |

286 |

416 |

| 130 |

135 |

150 |

166 |

182 |

260 |

200 |

260 |

310 |

450 |

| 140 |

146 |

162 |

178 |

196 |

280 |

215 |

280 |

334 |

485 |

| 150 |

156 |

173 |

191 |

210 |

300 |

230 |

300 |

358 |

520 |

| 200 |

208 |

231 |

255 |

280 |

400 |

307 |

400 |

477 |

693 |

| 250 |

260 |

289 |

319 |

350 |

500 |

384 |

500 |

596 |

866 |

| 300 |

312 |

346 |

382 |

420 |

600 |

460 |

600 |

715 |

1039 |

| 350 |

364 |

404 |

446 |

490 |

700 |

537 |

700 |

834 |

1212 |

| 400 |

416 |

462 |

510 |

560 |

800 |

614 |

800 |

953 |

1386 |

| 450 |

469 |

520 |

573 |

630 |

900 |

691 |

900 |

1073 |

1559 |

| 500 |

521 |

577 |

637 |

700 |

1000 |

767 |

1000 |

1192 |

1732 |

| 550 |

573 |

635 |

701 |

770 |

1100 |

844 |

1100 |

1311 |

1905 |

| 600 |

625 |

693 |

764 |

840 |

1200 |

921 |

1200 |

1430 |

2078 |

| 650 |

677 |

751 |

828 |

910 |

1300 |

998 |

1300 |

1549 |

2252 |

| 700 |

729 |

808 |

892 |

980 |

1400 |

1074 |

1400 |

1668 |

2425 |

| 750 |

781 |

866 |

956 |

1050 |

1500 |

1151 |

1500 |

1788 |

2598 |

| 800 |

833 |

924 |

1019 |

1120 |

1600 |

1228 |

1600 |

1907 |

2771 |

| 850 |

885 |

981 |

1083 |

1190 |

1700 |

1304 |

1700 |

2026 |

2944 |

| 900 |

937 |

1039 |

1147 |

1260 |

1800 |

1381 |

1800 |

2145 |

3118 |

| 950 |

989 |

1097 |

1210 |

1330 |

1900 |

1458 |

1900 |

2264 |

3291 |

| 1000 |

1041 |

1155 |

1274 |

1400 |

2000 |

1535 |

2000 |

2384 |

3464 |

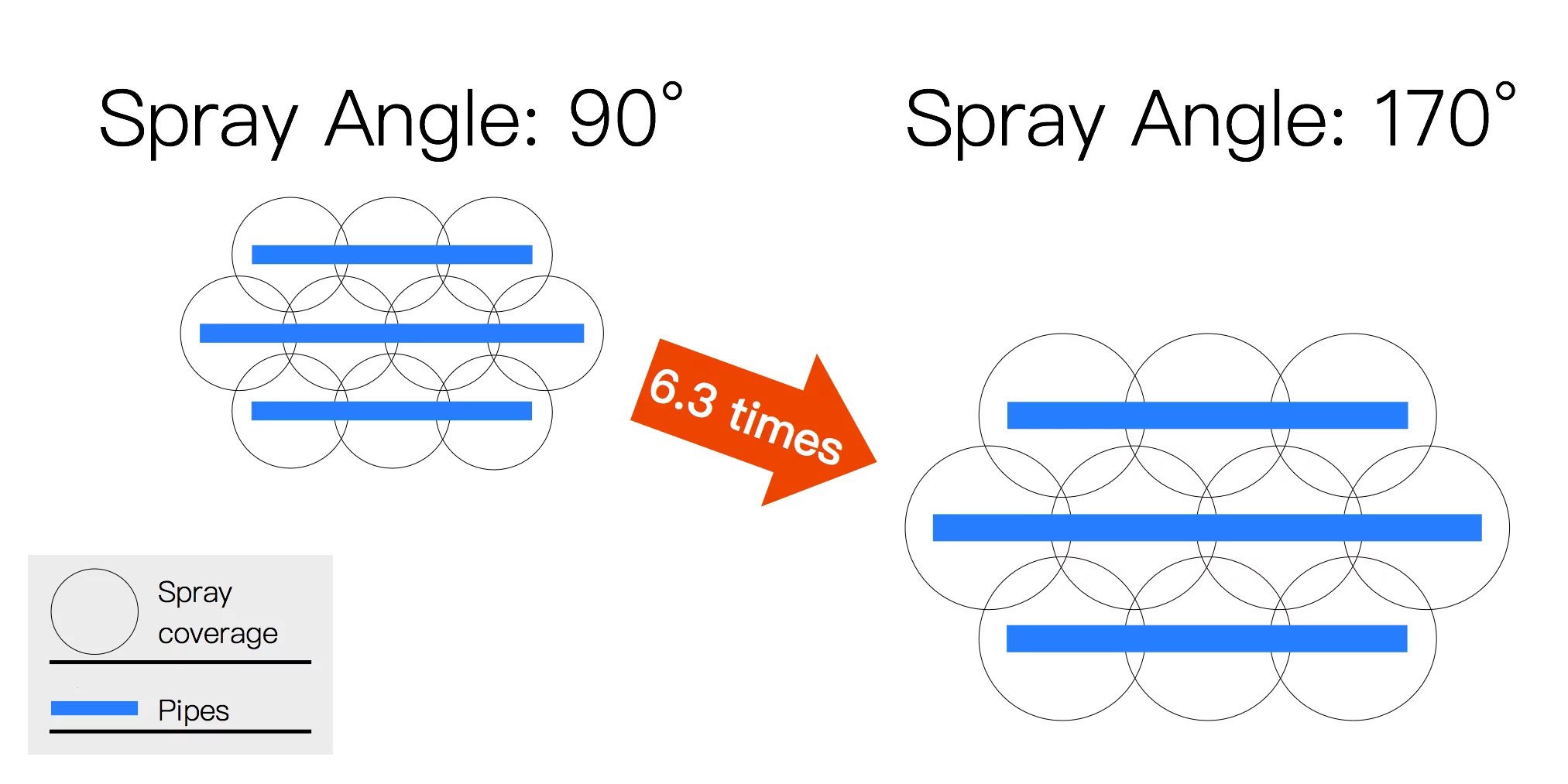

5. About Angles and Coverage Areas

At a distance of 300 mm, theoretical spray area:

- 90° angle: 60cm, 0.28㎡ per unit

- 170° angle: 150cm, 1.76㎡ per unit (approximately 6.3 times)

4. 3 Key Distance Decisions for Choosing Nozzle Angles

1 ) Distance to Target

The distance between the nozzles and the target area, such as a plant canopy, significantly affects spray deposition. Optimal distance settings ensure efficient coverage while minimizing drift and wastage. Adjustments should consider the type of spray and the specific application requirements to maximize efficacy.

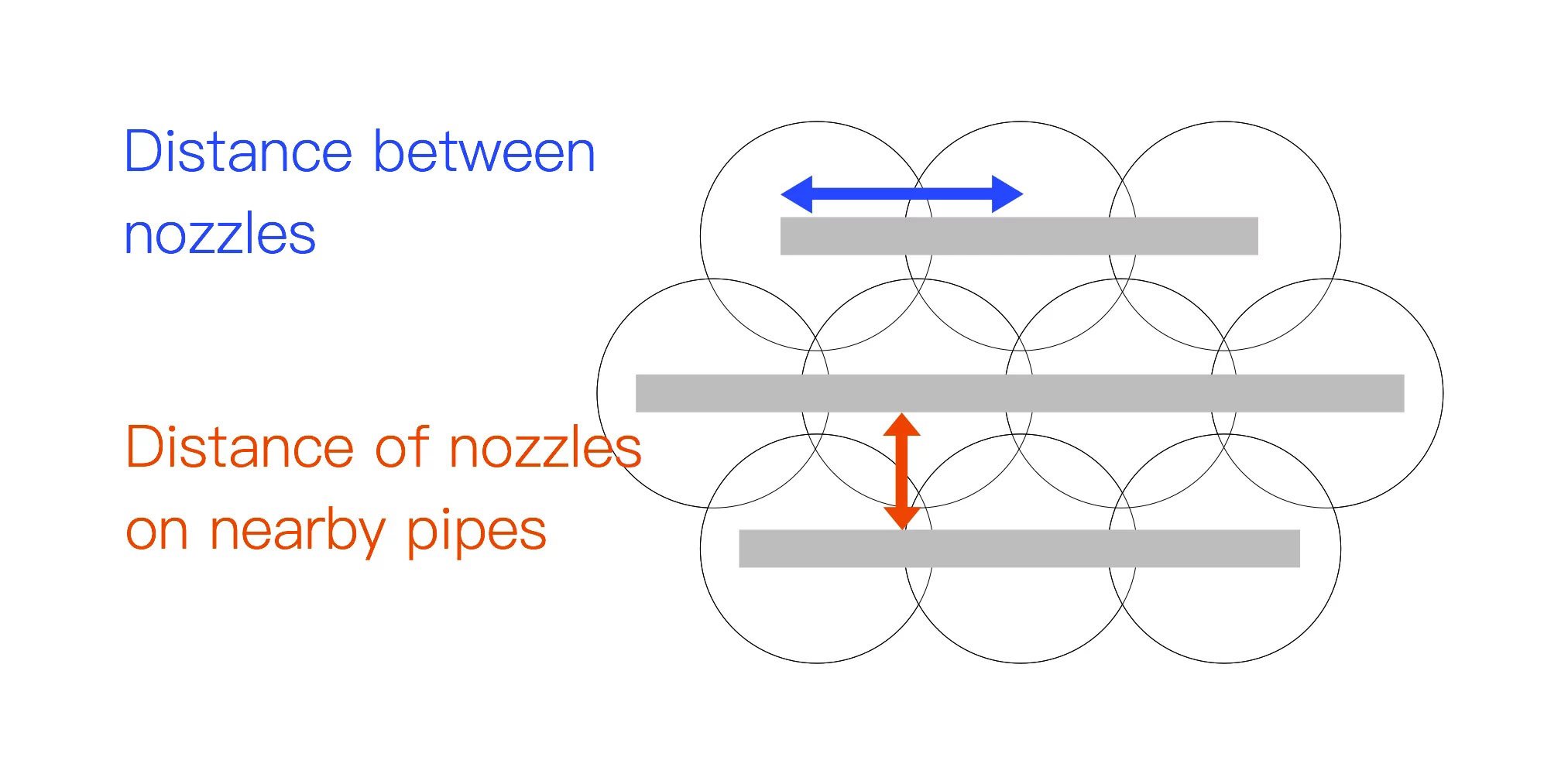

2 ) Distance Between Adjacent Nozzles

Maintaining the right distance between adjacent nozzles is crucial for achieving uniform coverage across the target area. Incorrect spacing can lead to overlapping spray zones or missed areas, affecting the overall effectiveness of the application. This distance varies depending on the nozzle type and the desired coverage pattern.

3 ) Distance Between Spray Bars

For non-fan nozzles, such as solid cone, hollow cone, and spiral nozzles, the distance between spray bars plays a critical role in angle selection and, consequently, in the coverage pattern and effectiveness of the spray. Proper adjustment ensures optimal spray overlap and uniform distribution across the target.