There are various types of nozzles with distinct functions, ranging from fan-shaped nozzles and solid cone nozzles to hollow cone nozzles and spiral nozzles. Different spray patterns not only affect the coverage area but also influence the intensity and effectiveness of the spray. Choosing the right nozzle is, therefore, a nuanced task. This article will guide readers through the characteristics of different nozzle spray patterns, flow field distributions, and more.

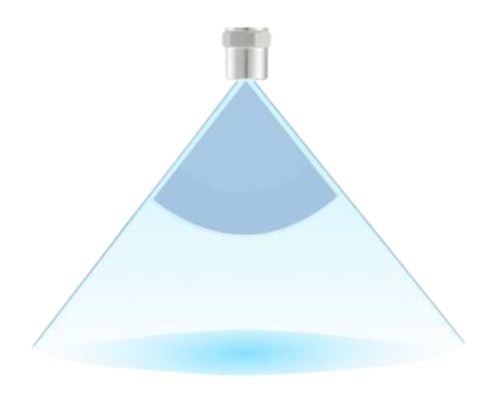

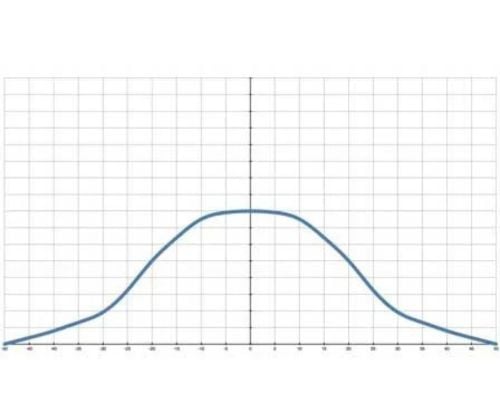

1 ) Flat Fan Spray Nozzles

Flat Fan Nozzles Spray Patterns: Single-fluid fan-shaped nozzles are named for their spray pattern, which resembles a fan as water exits the nozzle.

Fan-shaped nozzle coverage pattern: When sprayed onto a target, the coverage shape is a single line with tapered edges on both sides.

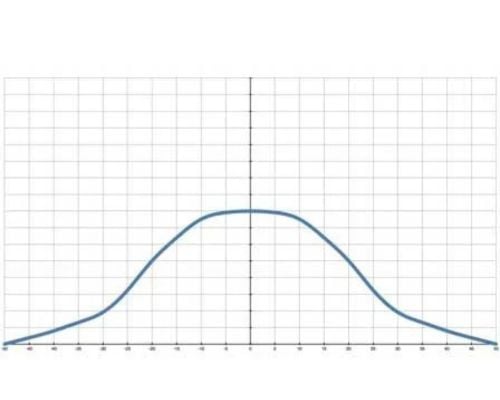

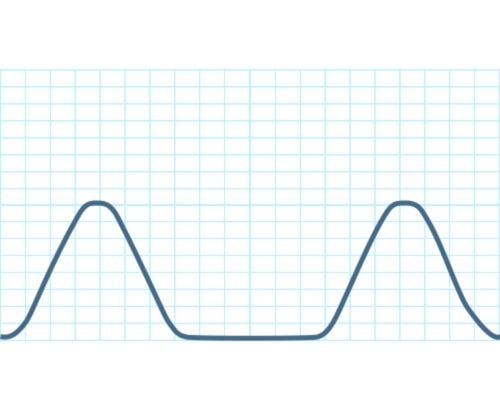

Flat fan spray nozzle flow distribution: Displays a bell-shaped flow pattern, with stronger intensity in the center and gradually weaker edges.

Flat fan spray nozzles are ideal for applications requiring uniform linear coverage, such as conveyor belt cleaning, surface treatment, distribution, coating, and dust suppression.

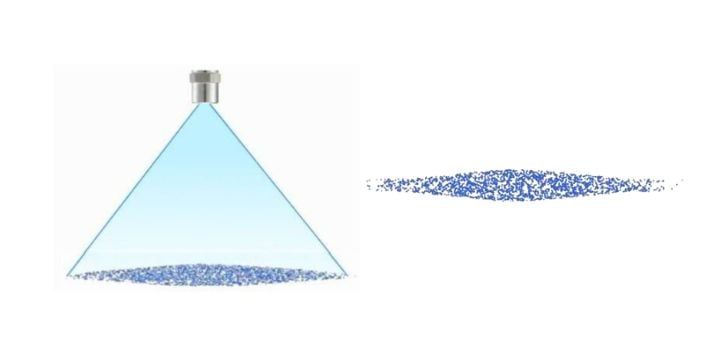

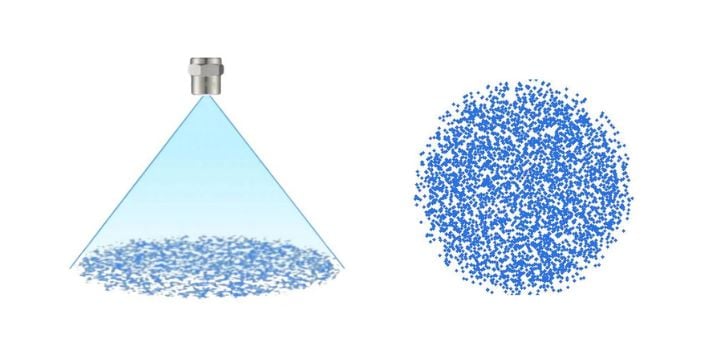

2 ) Solid Cone Spray Nozzles

Solid cone nozzles produces a fully filled cone-shaped spray pattern as it discharges liquid or gas. The spray expands outward from the center of the nozzle, with a uniform droplet density throughout the coverage area and no gaps.

Solid cone nozzle coverage pattern: When the spray lands on a surface, it forms a solid circular coverage area.

Solid cone nozzle flow distribution: Similar to fan-shaped nozzles, it exhibits a bell-shaped flow pattern with stronger intensity in the center and gradually weaker edges.

Solid cone sprays are used for applications requiring dense liquid coverage over large areas, such as cooling systems, water mist fire suppression, and chemical equipment cleaning.

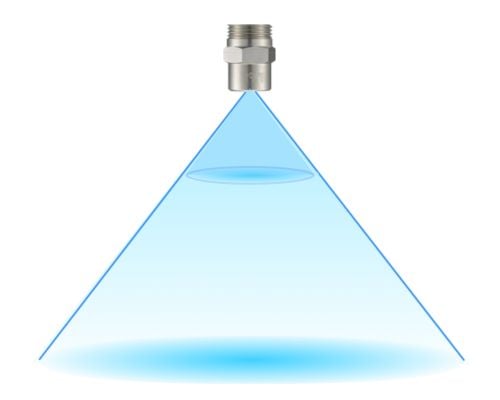

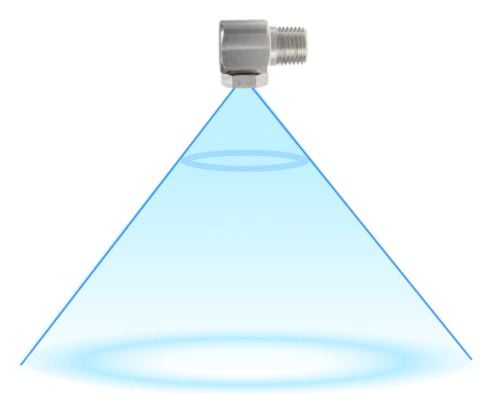

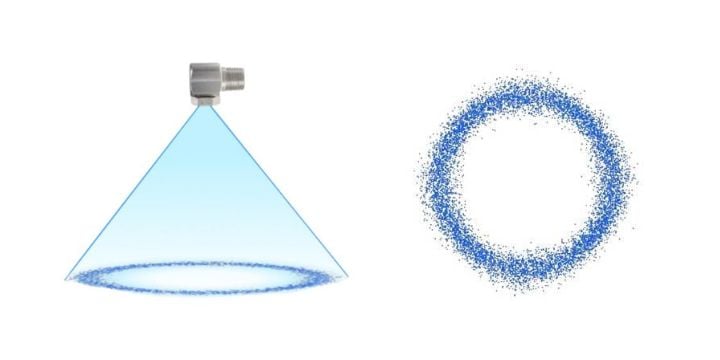

3 ) Hollow Cone Spray Nozzles

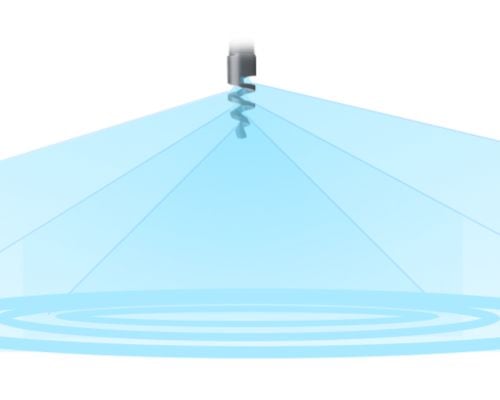

Hollow cone nozzle spray pattern: The spray forms a hollow cone shape, where the mist is concentrated along the outer edges of the cone, leaving the center area empty.

Hollow cone nozzle coverage pattern: When the spray lands on a surface, it creates a ring-shaped coverage area around the perimeter, with the center remaining empty.

Hollow cone nozzle flow distribution: It exhibits a valley-shaped flow pattern, with stronger intensity at the edges and weaker intensity in the middle.

Hollow cone nozzles produce fine droplets, making them ideal for applications requiring uniform atomization and liquid conservation, such as air humidification, dust suppression, and environmental cooling in outdoor or industrial facilities.

4 ) Other Nozzles

Spiral Spray Nozzles

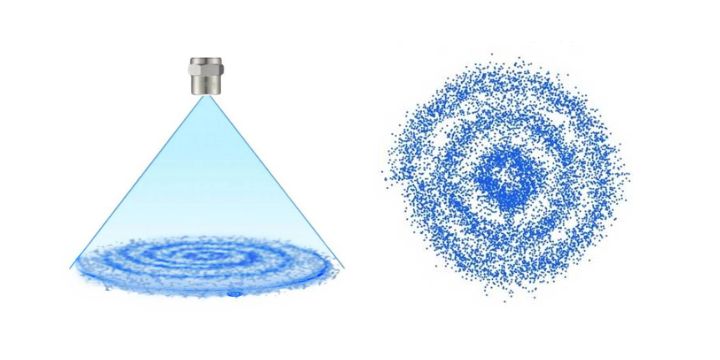

Spiral nozzle spray pattern:

Designed with a spiral structure, also known as a pig-tail or mosquito-coil nozzle, it produces a solid circular spray pattern.

Spiral nozzle coverage pattern: The spray coverage pattern of a spiral nozzle consists of multiple concentric circles.

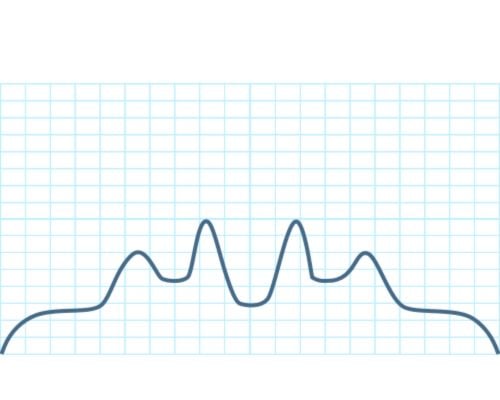

Spiral nozzle flow distribution: The flow distribution of a spiral nozzle exhibits multiple valley-shaped patterns. The peaks of the valleys decrease progressively from the center outward, with the edges gradually weakening.

Spiral sprays are designed to resist clogging and provide rapid coverage over large areas. They are ideal for use in gas scrubbers, desulfurization systems, industrial fire suppression, disinfection, and dust control.

Linear Jet Nozzles

Nozzle Type: Needle nozzle, flat jet nozzle.

Shape Description: A linear spray pattern with a thin, concentrated water stream.

Features: High pressure and high velocity, delivering strong impact force.

Ideal for removing stubborn stains or deposits.

Can be paired with high-pressure pumps for long-distance cleaning.

Curtain Spray Nozzles

Nozzle Type: Water curtain nozzle.

Shape Description: A wide, uniform thin layer of water, creating a "water wall" or "barrier" effect.

Features: In fire scenarios, the water curtain acts as a barrier to prevent the spread of flames and heat, block smoke, toxic gases, or fire, and rapidly absorb heat to lower ambient temperatures.

Curtain sprays can also serve decorative purposes, such as in water shows or fountain displays.

Dual Fluid Spray

Nozzle Type: Air atomizing nozzle.

Shape Description: Produces extremely fine mist, resembling fog or smoke, and can be designed as a cone (solid or hollow) or fan shape depending on the application.

Features: High-precision atomization, suitable for applications like painting automobiles and furniture or humidification.

Also effective for dust suppression and cooling purposes.

[1]