With a plethora of flow meter options available on the market, choosing the right one is crucial for ensuring measurement accuracy and reliability. An inappropriate flow meter selection can result in measurement errors or incorrect calibration, affecting data precision. Hence, understanding the interrelation between flow, velocity, and pipe diameter is essential before selecting a suitable flow meter. This article will delve into this topic, helping you choose the flow meter that best meets your needs.

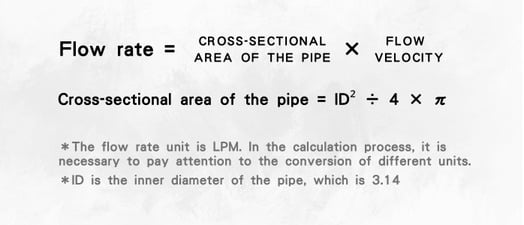

1. How to Calculate Flow Rate from Pipe Size?

The relationship between flow, velocity, and pipe diameter can be calculated with the following formula, keeping in mind the conversion between different units. Here's an example illustrating how to use the formula: For a 2-inch diameter pipe with a flow velocity of 1 m/s, the flow rate can be determined as follows: The internal diameter (ID) of a 2-inch pipe is 51mm. By applying the pipe cross-sectional area formula (area = ID² ÷ 4 × π), we find the area to be 0.002041785 m². Multiplying the pipe cross-sectional area by the flow velocity gives us a flow rate of 122.5071 L/min (LPM).

When calculating, it's important to convert between different units. Here's a simple example demonstrating how to use the flow rate calculation formula: Suppose there is a pipe with a 2-inch diameter and a flow velocity of 1 m/s. The question is, what is the flow rate?

For a 2-inch pipe with an internal diameter (ID) of 51mm, the cross-sectional area is calculated using the formula (Area = ID² ÷ 4 × π), resulting in an area of 0.002041785 m². Then, by multiplying the cross-sectional area by the flow velocity, according to the flow rate formula (Flow rate = Cross-sectional area × Flow velocity), the flow rate is determined to be 122.5071 liters per minute (LPM).

[1]

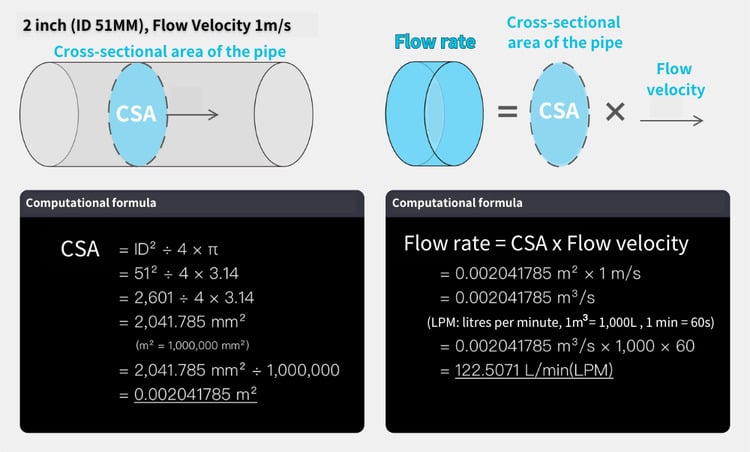

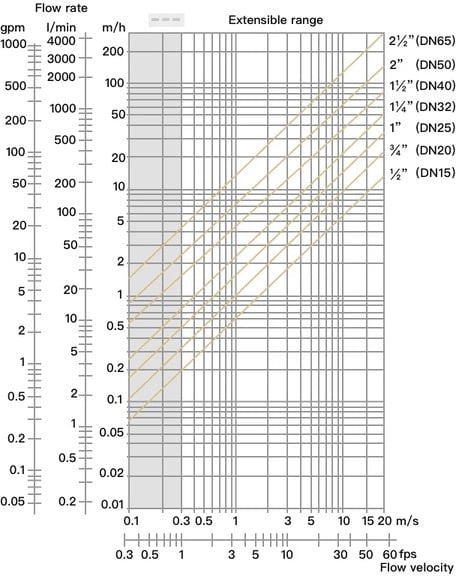

2. Choose the Most Suitable Flow Meter by Relating Flow, Velocity, and Pipe Diameter:

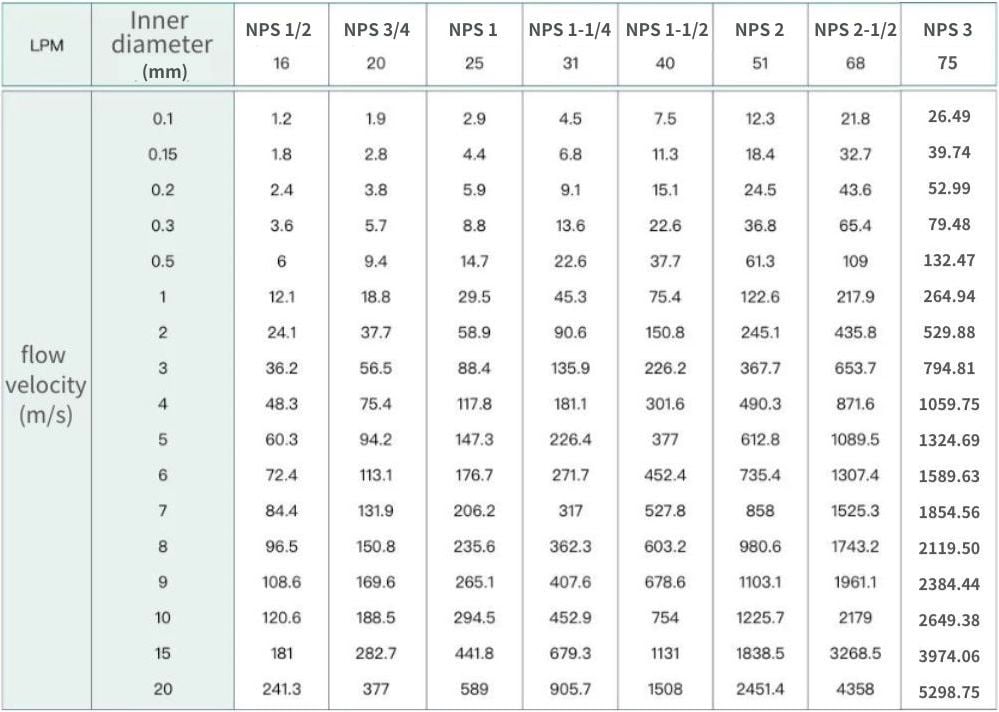

Using the formula above, LORRIC has compiled a chart to deduce the third variable when only two are known, such as flow rate and pipe diameter, to identify the suitable velocity. This data helps in selecting the right model of flow meter for your needs.

Flow Rate, Flow Velocity, and Pipe Diameter Table (Imperial)

Flow rate unit: GPM (US gallon/min), Flow velocity unit: ft/s, Pipe diameter unit: inch

Usage Examples:

Example 1: For a 0.622 inch pipe diameter, at a flow velocity of 0.3 ft/s, the flow rate is 0.28 GPM.

Example 2: For a 1 inch pipe diameter, at a flow velocity of 10 ft/s, the flow rate is 26.94 GPM.

Flow Rate, Flow Velocity, and Pipe Diameter Table (Metric)

Flow rate unit: LPM (L/min), Flow velocity unit: m/s, Pipe diameter unit: mm

Usage Examples:

Example 1: For a 16mm (1/2 inch) pipe diameter, at a flow velocity of 0.1 m/s, the flow rate is 1.2 LPM.

Example 2: For a 25mm (1 inch) pipe diameter, at a flow velocity of 1 m/s, the flow rate is 29.5 LPM..

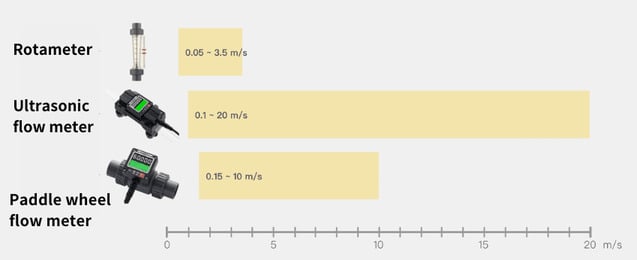

Here are the applicable flow velocity ranges for different types of LORRIC flow meters for your reference:

The applicable flow velocity ranges for LORRIC flow meters by type are as follows: Variable Area (Float Type) Flow Meters: 0.05 ~ 3.5 m/s; Ultrasonic Flow Meters: 0.1 ~ 10 m/s; and AxleSense Paddle Wheel Flow Meters: 0.15 ~ 10 m/s. Notably, AxleSense Paddle Wheel Meters incorporate patented axle sensing technology, offering a range that is twice as extensive as similar products from other brands.

3. Understanding Flow Velocity and Flow Rate

1 ) What is Flow Velocity?

Flow Velocity is the speed at which fluid moves, measured by the distance traveled per unit of time.

[2]

2 ) What is Flow Rate?

Flow rate refers to the amount of fluid (liquid or gas) or charge passing through a specific cross-section per unit of time (the corresponding SI base unit is seconds). The amount of fluid can be measured in terms of volume or mass, while the amount of charge is measured in coulombs.

The commonly heard LPM stands for liters per minute (liter/minute [L/min]), indicating the volume of liquid flowing per minute. It is often used to measure liquid flow rates, such as in water treatment equipment and the delivery rate of liquids in medical devices.

For quick flow unit conversions, visit

online flow converter.

3 ) Flow Meter Selecting Guide:

- Principle of flow conservation: Flow rate remains constant throughout a leak-free, branchless pipeline, so install the meter in a stable location for consistent measurements.

- Flow velocity inversely relates to pipe diameter at a constant flow rate, so avoid connecting large pipes to small meters to prevent energy loss and exceeding the meter's measurement range.

- Be aware of internal diameter differences in pipes of the same type but different standards, as this can significantly affect flow rate calculations.

- Pay attention to unit conversion during calculations, such as milliliters to liters and millimeters to meters, to ensure accuracy.