Fluid experts at LORRIC are dedicated to product R&D, improvement, and customer service. They aim to contribute to the industry by sharing technological advancements and boosting competitiveness. Recently, LORRIC has been thinking about ways to grow together with Taiwan's industry beyond launching innovative electronic fluid sensing equipment. During routine industry research, they stumbled upon a thesis by Rui-Teng Lai, a master's degree holder from Da-Yeh University's Department of Industrial Engineering and Technology Management, titled "The Effect of Flat Plate Inclination Angle on Cleaning Effectiveness in a Two-Fluid Nozzle System". This discovery sparked the idea of turning LORRIC into a platform for sharing industrial technology information and academic exchanges. Besides showcasing LORRIC's products and technology, they aim to uncover more fluid experts within the industry, guiding further assistance to the industry through interviews with experts, hoping to one day elevate Taiwan's overall industry.

Rui-Teng Lai is currently the co-founder of DaoPin Co., Ltd., a company specializing in genetic engineering. However, transitioning from two-fluid nozzle systems to genetic engineering, what research experience did Mr. Lai have in fluid dynamics during his master's, and what can we learn from it?

Mr.Lai's Insight for Two-Fluid Nozzle Systems

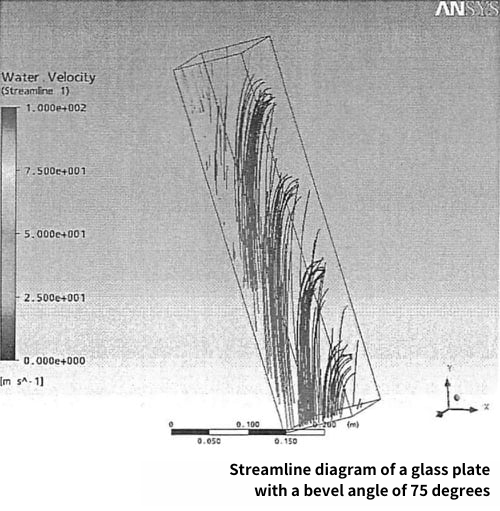

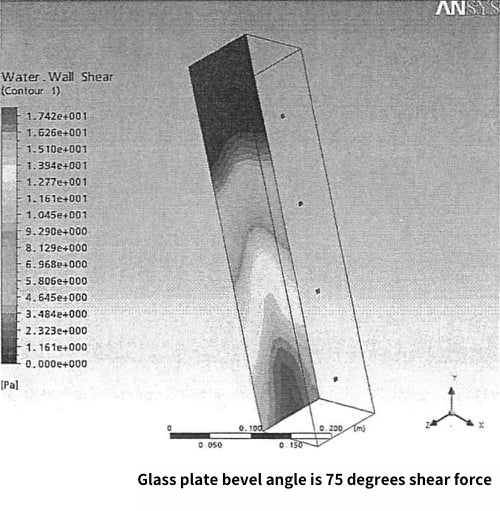

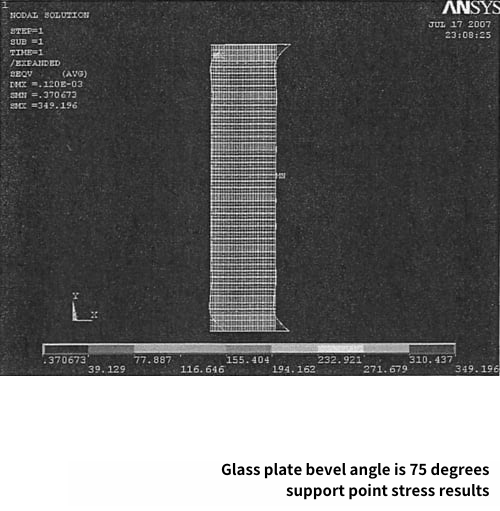

This study investigates the effect of the flat plate inclination angle in a two-fluid nozzle system on cleaning effectiveness, while also examining the impact of inclination angle on the stress generated at support points during transfer. The analysis integrates the results of stress and shear force generated by the glass plate's inclination angle with multi-objective decision-making methods to determine the desired objectives, analyzing the optimal flat plate inclination angle, shear force, and water flow speed for meeting particle cleaning requirements. An efficient analysis process and the finite element method software ANSYS CFX, a general-purpose computational fluid dynamics software, were used to model the design of the flat plate inclination angle in the two-fluid nozzle system, as well as to simulate results such as the inclination angle of the glass plate, shear force, water flow speed, edge displacement, and stress at support points.

.

The study sets shear force and speed as goals, utilizing multi-objective decision-making methods to determine the range of flat plate inclination angles. As the angle increases, both shear force and speed increase, but the relationship with support point stress must be considered. Therefore, the result cannot simply be the maximum inclination angle but must be an angle that complies with the maximum support stress.

LORRIC had the privilege to discuss with Mr. Lai about his research on "The Impact of Flat Plate Inclination Angle on Cleaning Effectiveness in a Two-Fluid Nozzle System," his research process, journey, outcomes, and achievements. Through Mr. Lai's past efforts, we can explore Taiwan's local research environment and capabilities.

The Case Study for the Perfect Inclination Angle in Glass Cleaning

In Taiwan's flat panel wet process industry, besides the well-known printed circuit board sector, the panel industry is another significant player. Manufacturers have been developing both hanging and inclined types. Mr. Rui-Teng Lai's research team from the Department of Industrial Engineering and Technology Management at Da-Yeh University utilized results simulated by ANSYS, and the collaborating manufacturers achieved better outcomes than their initial goals from the experiments.

Mr. Lai mentioned that during the initial collaboration with a Taiwanese panel manufacturer for industry-academia technical cooperation, the foreign technical consultant of the panel factory suggested an inclination angle for cleaning the machinery glass during the process. However, after taking on this collaboration, the leading professor of Mr. Lai's team, due to his profound familiarity with ANSYS and using his own researched equations, found the optimal glass cleaning inclination angle for the Taiwanese factory, which was beyond the foreign consultant's expectations and yielded excellent actual test results.

How Precise Angles Can Boost Manufacturing Yields

In the initial phase of collaboration, the foreign technical personnel involved in the research suggested that the inclination angle of the equipment didn't need to be large. However, research and simulations revealed that the angles proposed by the foreign consultants did not yield the ideal yield rates for the equipment. It was found that simply adjusting the inclination angle of the glass on the existing equipment and properly setting the rollers could achieve a better inclination effect, significantly improving the yield rate for the collaborating Taiwanese factory.

Mr. Lai mentioned that the thesis involved simulating flow lines, with the primary goal of determining the equipment's cleaning capability, such as how to remove the most particles. The inclination angle suggested by the foreign consultant could carry away only a few particles; some suggested trying a vertical angle, but simulations showed that vertical angles were impractical due to the bending caused by side spraying from the nozzles, leaving little fluid for effective glass cleaning, especially for the upper part of the glass. Thus, the inclination angle consideration was how to cover areas on the panel, primarily using rollers at the bottom rather than hanging methods. The final results of the study surprised the foreign consultants, as the initial ideas and actual outcomes differed significantly.

Mr. Lai explained that it was only after further communication with the client that he understood that the foreign consultants' recommendations were simply stating that certain angles were better without explaining the rationale behind their decisions. This approach worked for early products, but as the complexity increased with the 8.5 generation, Taiwanese manufacturers needed to further optimize their cleaning capabilities and try to find angles that resulted in better cleaning effects.

Ensuring Cleanliness to Avoid Contamination in Subsequent Processes

Mr. Lai highlighted that their simulations of particles sprinkled on the glass surface aimed to observe whether the flow field was sufficient and how quickly it could remove these particles. They discovered that the efficiency of the inclination angles suggested by foreign consultants was too low, leading to high water consumption costs. Moreover, if the cleaning process was too slow, it could affect other processes, or if not clean enough, it could contaminate the next process.

Considerations for Nozzle Selection

Mr. Lai mentioned in the experiments, due to the dual-fluid nozzles having more parameters, the effect under different conditions varied significantly, necessitating assistance from nozzle manufacturers. Based on LORRIC's experience in particle size testing, the distribution and speed of particles vary with different gas-liquid ratios. The industry often estimates about a threefold speed difference, but the actual complexity of the data far exceeds such a simple multiplier, requiring long-term cooperation with clients.

Professor's Proficiency with ANSYS Yields Optimal Results

During the interview, Mr. Lai emphasized that their laboratory's use of ANSYS differed from others in the industry because the professor had extensive experience with ANSYS. The entire experiment ran on equations (UDF) created by themselves, with at least 48 equations for a single element. This approach allowed them to obtain the needed results in the shortest time possible, and the professor's knowledge of various methods to narrow down the simulation scope led to ideal outcomes.

Bridging the Gap: LORRIC's Embrace of Academic Excellence to Elevate Industry Standards

LORRIC empathizes deeply with Mr. Lai's research experience, recognizing the years of accumulated know-how in nozzle design and manufacturing. However, they observe that some customers underestimate Taiwanese products, dismissing them as lacking sophistication and favoring foreign expertise due to a perception that "the grass is greener on the other side." This mindset leads to a preference for higher-priced foreign brands and forces Taiwanese products into a price-cutting competition, which hinders industry advancement. LORRIC believes this interview changes the perspective on Taiwan's academic and technical standards.

Moreover, as Mr. Lai's thesis on industry-academia collaboration demonstrates, the academic sector can offer the industry more research outcomes that blend theory with practical technology, potentially solving more problems at lower costs. This could widen the profit margins for the industry, while schools gain academic achievements and experience in industrial cooperation. Such a collaboration model is highly promotable and marks the beginning of LORRIC's anticipation for further exchanges with the academic world.

The Transition to Biomedical Research: Journey and Transformation

After graduating from Da-Yeh University with a master's in Industrial Engineering, Mr. Lai joined a biomedical research project at Academia Sinica, which later spun off to form DaoPin Co., Ltd., making him a co-founder of the startup.

Mr. Lai shared that DaoPin originated from genetic sequencing research at Academia Sinica, focusing on identifying mutant cells and finding accurate countermeasures. DaoPin's technology can deliver results within a day, compared to the two-week norm abroad, significantly benefiting emergency medical diagnostics and treatments.

Currently, Mr. Lai leads the development of high-computation technology at DaoPin. His expertise in ANSYS analysis during his master's studies, particularly in high-computational areas, plays a crucial role in processing the vast amount of genetic data, ensuring DaoPin's genetic sequencing services lead the industry in speed.

Discussing funding, Mr. Lai humorously noted that while they've had discussions about angel investment, DaoPin's current financial stability and profitability mean they're looking for investors who can contribute to the company's growth. DaoPin's potential in the medical field is promising, and LORRIC wishes Mr. Lai and DaoPin success, hoping Taiwan's biomedicine sector can shine globally thanks to talented individuals and companies.