Overview

- Hysteresis is defined as the dependency of a system's state on its historical changes, impacting various materials and technologies such as hard disk drives and magnetic fields.

- Hysteresis is integral for accurate measurements and system reliability in sensor alarms and flow meters.

- Implementing hysteresis improves system stability and reduces false alarms.

Hysteresis is a pivotal feature in the realm of flow meters and sensor alarms, where precise control and measurement are paramount. It embodies the system's inherent delay or the lag in response when experiencing changes in input or environmental conditions

1. What is Hysteresis?

Hysteresis is a phenomenon in which the relationship between the input and output of a system depends on the history of the system. In other words, the output of the system depends not only on the current input, but also on the previous inputs.

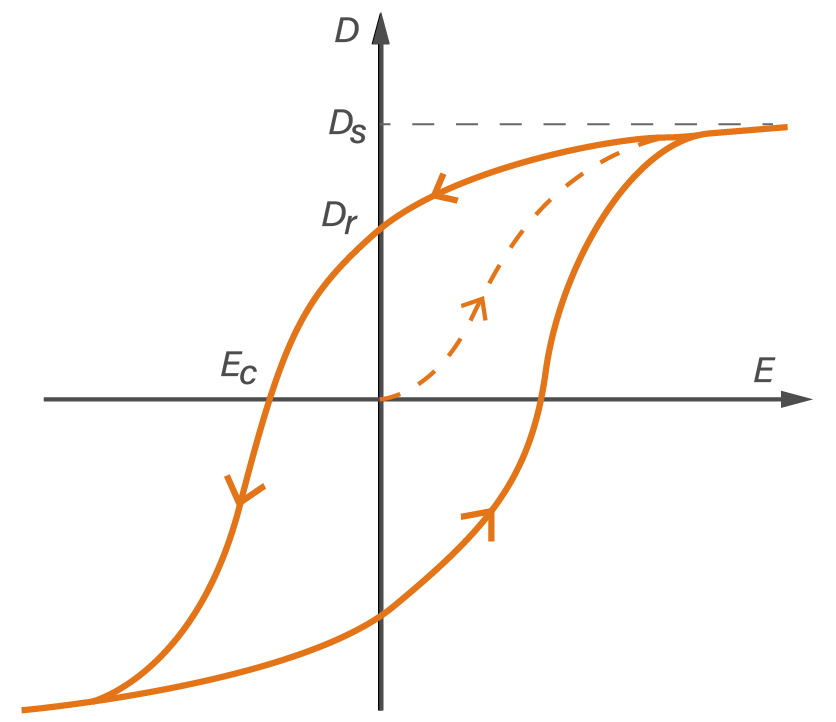

One example of hysteresis is the behavior of a magnetic material. When a magnetic field is applied to a magnetic material, the material becomes magnetized. However, when the magnetic field is removed, the material does not completely demagnetize. Instead, it retains some of its magnetism. This is because the magnetic domains in the material have been aligned by the magnetic field, and they do not return to their original state when the field is removed.

Hysteresis is also observed in other systems, such as ferroelectric materials, shape memory alloys, and biological systems.

2. Hysteresis Accurate Flow Measurement

Flow meters sensors with hysteresis can provide more accurate and reliable flow measurements than those without hysteresis. Hysteresis is the dependence of the output of a sensor on its history. In the case of flow meters, hysteresis can cause the output to lag behind the actual flow rate. This can lead to inaccurate readings, especially when the flow rate is changing rapidly.

[3]

3. Hysteresis Range Settings: Selecting the Optimal Range

Hysteresis is the non-linear relationship between a sensor's input and output. In flow meters, hysteresis can cause the output to lag behind the actual flow rate. This can lead to inaccurate readings, especially when the flow rate is changing rapidly.

The hysteresis range is the range of input values over which the output of a sensor exhibits hysteresis. The optimal hysteresis range is the range that minimizes the error in the output of the sensor.

The optimal hysteresis range can be selected by considering the following factors:

- The accuracy requirements of the application

- The range of input values that the sensor will be exposed to

- The cost of the sensor

Example: Application-Flow Meter

- Accuracy Requirement: Flow must be accurately measured to ±5%.

- Sensor's Exposed Input Range: 0 LPM to 1000 LPM.

- Sensor's Cost: Medium cost.

- Optimal Hysteresis Range: ±25 LPM.

In flow meter applications, the accuracy requirement is ±5%, meaning the deviation between the flow meter's output value and the actual flow cannot exceed ±5%; the sensor's exposed input range indicates that the flow meter needs to be able to measure flows between 0 to 1000 LPM; the sensor's cost being medium implies that manufacturers of flow meters need to balance between cost and performance, and setting the optimal hysteresis range at ±25 LPM indicates that the flow meter's output value will not change within a ±25 LPM range.

The reasons for choosing ±25 LPM

1. The flow meter requires high accuracy, so the hysteresis range cannot be too large.

2. The sensor has a medium cost, thus the hysteresis range cannot be too small.

If the hysteresis range is too small, the flow meter's output value will change with minor variations in flow, which would decrease the flow meter's accuracy. If the hysteresis range is too large, the flow meter's output value might lag behind the actual flow, which would also reduce accuracy.

A hysteresis range of ±25 LPM balances the flow meter's accuracy and cost. It ensures the flow meter's output value is within the accuracy range of ±5%, while also reducing the cost of the flow meter.

In specific applications, the hysteresis range can be adjusted based on the requirements for accuracy, cost, and response time. For example, if higher accuracy is required, the hysteresis range can be reduced to ±10 LPM. If a higher emphasis is placed on cost, the hysteresis range can be increased to ±50 LPM.

Other examples

Here are some specific examples:

- Chemical Plant: Flow meters used in chemical plants often require higher accuracy to ensure the safety and stability of the production process. Therefore, the hysteresis range can be set to ±10 LPM.

- Water Treatment Plant: Flow meters used in water treatment plants often prioritize lower costs to reduce operational expenses. Therefore, the hysteresis range can be set to ±50 LPM.

- Power Plant: Flow meters used in power plants often need quicker response times to ensure the safety and stability of power generation. Therefore, the hysteresis range can be set to ±25 LPM.

4. LORRIC Flowmeter Alarm Stability via Hysteresis

The relationship between output and flow rate:

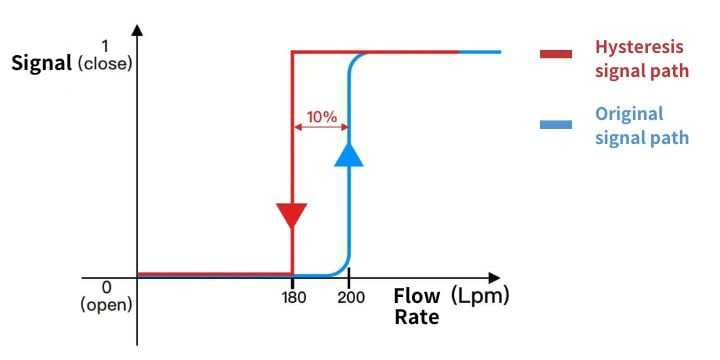

Under the original signal route (blue line in image below), assume 200 LPM as the trigger value for the red light alarm, 0 (open) makes the red light turn off and 1 (close) turns the red light on.

If the flow data swings between 199 and 201 LPM with no hysteresis, the red light will turn off when the value is 199 Lpm; the red light will blink at 201 LPM, and the light will continue to change, blinking, turning off, blinking, turning off, and so on, which is likely to interfere with field operations. If a hysteresis percentage is set to 10%, the signal must be lower than 10% of 200 LPM, that is, 180 LPM (red line in image below) to turn off red light.

FP-AS510 Patent AxleSense Paddlewheel Flowmeter

Made in Taiwan and featuring the patented AxleSense technology, Inspected and proofed by SGS, RoHS compliant, the FP-AS510 has a measuring range that doubles that of other brands, which allows for the detection of any disappearance of the paddle which tends to cause zero-flow problems, on top of large indicator lights and a large screen that allows for more convenient on-site supervision.