What is O-Ring?

O-Rings, known for their sealing capabilities, are used extensively in industrial applications like pipelines, pneumatic and hydraulic systems, and mechanical seals. They are made from highly elastic rubber materials and come in various sizes and shapes, including the most common round form, as well as square, flat, and rectangular.

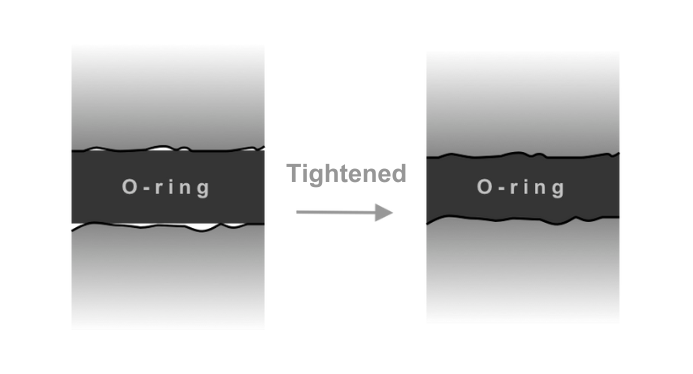

How O-Ring Works?

Despite being solid, O-Rings act like a high-viscosity, incompressible liquid that stretches and expands to fill gaps between sealing grooves and surfaces, creating a tight seal against gas or liquid leaks. Their simplicity and reliability make them a common choice in mechanical design for sealing.

[1]

Advantages and Characteristics of O-Rings

- Low cost, small size, lightweight, infrequent replacement.

- Good wear resistance and chemical corrosion resistance.

- Simple installation, effective sealing.

- Seals across broad pressure, temperature, and tolerance ranges.

- No critical torque, reducing structural damage risk.

- Durable in high-density component connections.

- Easy to identify functional failures.

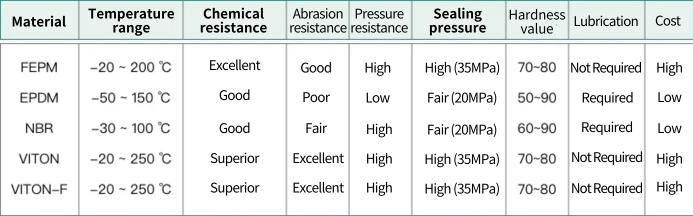

Choosing the Right O-Ring Material

Selecting the right O-Ring involves considering factors like chemical compatibility, operating temperature, sealing pressure, lubrication requirements, hardness, size, and cost. Materials like FEPM, EPDM, NBR, VITON, and VITON-F offer various properties, with the choice significantly impacting the O-Ring's lifespan and performance.

*

Pressure Resistance: Refers to its ability to resist deformation or breakage under pressure. "Sealing pressure" is the maximum pressure it can withstand in actual use for effective sealing.

*

Sealing Pressure: The maximum pressure an O-ring must endure during use. Selection should consider the maximum pressure needed for sealing to prevent leaks or breakage.

*

Hardness Value: Measured in Shore A units (e.g., 70 Shore A). Higher values indicate harder materials, affecting sealing performance and elasticity.

*

Note: Consult with manufacturers before purchasing due to variations in O-ring compositions across different producers to ensure optimal performance.

Maintenance and Care of O-Rings

To ensure proper O-ring function, consider these maintenance tips:

- Choose the right material based on the fluid or gas to be sealed, and environmental factors like temperature and pressure.

- Clean surfaces before installing O-rings to ensure a smooth seal without dust or debris interference.

- Avoid over-compressing or stretching during installation to maintain elasticity and sealing effectiveness.

- Regularly replace O-rings as they wear out to maintain a good seal.

- Store O-rings in cool, dry places away from sunlight and chemicals to prevent damage.