Abstract

- Ultrasonic flow meters integrate with automation systems for real-time monitoring and data recording, suitable for various industrial applications.

- Dosing Principle: These systems precisely control the volume of each liquid dose, ensuring stable and accurate chemical dosing in industrial processes, typically using pumps or precision control devices.

- Accuracy Calibration: Regular calibration of flow meters and related equipment ensures dosing accuracy, involving comparisons between actual and target volumes, with adjustments made as needed to maintain precision.

In many industrial and scientific fields, accurate liquid input is crucial. Quantitative injection, a technique used to control the precise amount of liquid input, is widely applied in manufacturing, the chemical industry, medical fields, and other areas requiring controlled liquid input. This article introduces the basic concept and application of quantitative injection and discusses the importance of flow meters in this context.

1. Quantitative Injection and Its Industrial Applications

Quantitative injection, a technique used in labs and industrial settings, controls the flow and timing of liquids to precisely input required amounts. This ensures a specific amount of liquid is injected into a particular location within a set time. It's extensively used in the medical industry for precise drug component injection and direct body injection, in chemical engineering for accurate reactant ratios for stable and efficient reactions, and in food processing for exact additive and flavor injection to maintain product quality and consistency.

2. Advantages and Disadvantages of Quantitative Injection

The main advantage of using quantitative injection technology is its precision and efficiency, ensuring exact liquid input and faster operation. It also reduces costs since only the required amount is used. However, compared to traditional automatic control, quantitative injection equipment requires higher initial costs, so cost savings over setup costs need to be analyzed.

3. The Importance of Flow Meters in Quantitative Injection

Flow meters, instruments that precisely measure liquid or gas flow and convert it to electronic signals, are crucial in quantitative injection for measuring accurate solvent and drug component ratios. Integrated with other process control equipment, flow meters enable automated and precise control, improving production efficiency and product quality.

1 ) Principles of Quantitative Injection

Quantitative injection is achieved through controlling valve operations and precise flow meter measurements. The pump type is relatively unrestricted in actual applications, with common use of centrifugal, piston, and peristaltic pumps to provide fluid pressure, allowing fluid through valves into flow meters, then transported to the required location.

Quantitative injection primarily consists of three components: the control system, the actuating mechanism, and the detection elements.

- Control System: Comprised mainly of a computer control system and associated software, it can monitor and control parameters such as the flow, pressure, and temperature of the injected fluid in real time. The function of the control system is to receive signals from the actuating mechanism and detection elements and adjust the actuating mechanism according to predetermined control algorithms, achieving precise control over the amount of fluid injected.

- Actuating Mechanism: Converts commands from the control system into actual movement, primarily consisting of the actuating mechanism and valves. The actuating mechanism controls the opening and movement of valves to precisely regulate the injection speed and flow of the fluid.

- Detection Elements: Mainly include flow meters and pressure sensors among other components. The flow meter, one of the system's most crucial components, measures the fluid's flow rate in real time and transmits the measurement results to the control system, allowing for precise control of the injection amount. Flow meters are typically installed in pipelines to accurately measure the fluid's flow rate and transmit the data to the control system.

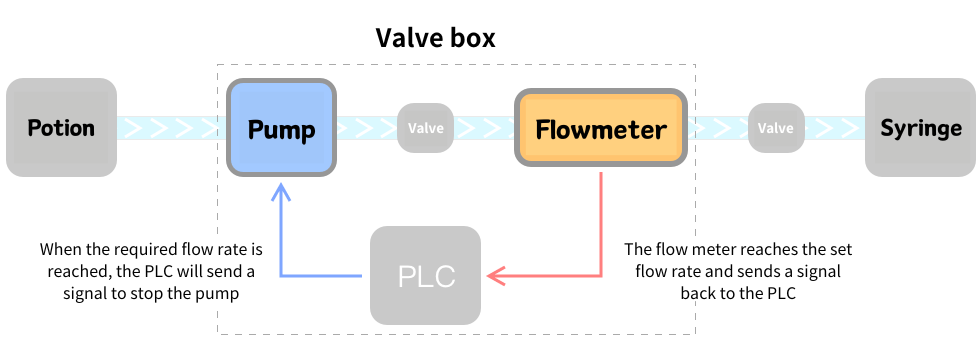

For example, suppose you need to inject 100L of liquid into the syringe. The first step is to set the PLC to execute the automatic control program for injecting 100L of liquid. When the PLC starts to execute the program, the pump and valve will open and inject the liquid. During the process, the flow meter will send the flow signal back to the PLC. When the cumulative flow reaches the set target of 100L, the PLC will stop the program execution. Therefore, the accuracy of the flow meter will be an important key factor in the dosing system.

2 ) Quantitative Injection's Accuracy Issues

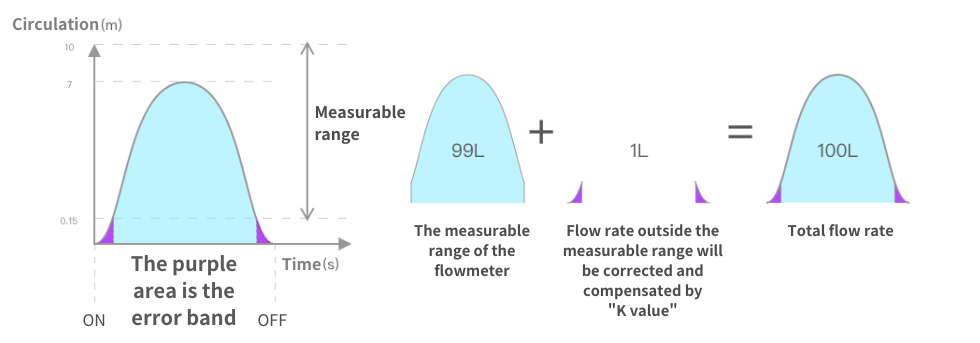

For example, using LORRIC's paddlewheel flow meter in a quantitative addition program, errors occur when liquid flow rates are outside the meter's measurement range (0m/s to 0.15m/s), requiring "K value" adjustments to correct inaccuracies.

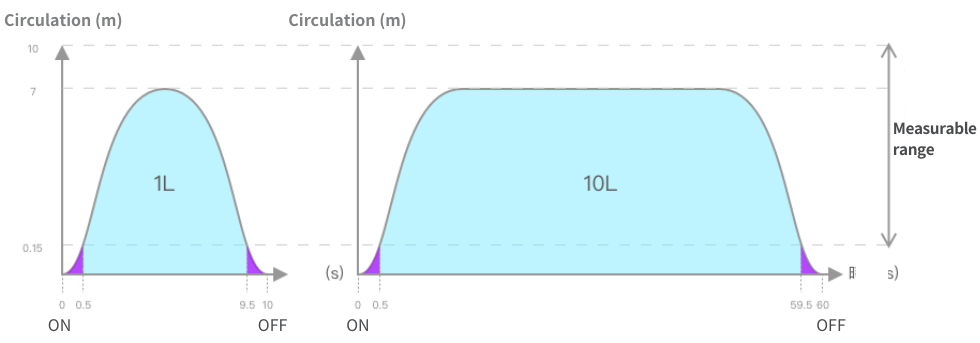

When setting different "quantitative" requirements, different K value corrections are needed: In a quantitative addition control system using a velocity-type flow meter, measurement errors occur because this type of flow meter cannot measure within the speed range of 0ms to its minimum measurable flow speed. When the control system has different "quantitative" needs, the variation in measurement duration leads to different error proportions in the overall flow calculation, necessitating different K values for correction. For example, injecting 1L of solution takes 10 seconds, and injecting 10L takes 60 seconds. Considering a combined error of 1 second before and after injection, the error for injecting 1L accounts for 1/10 of the total flow, while for 10L, it's 1/60, thus requiring different K values.

In summary, the principle of quantitative injection involves precise control of fluid injection amounts through the integration of the control system, actuating mechanism, and detection elements. Within this process, the flow meter, as one of the detection elements, plays a crucial role in the system's stability and accuracy. Since LORRIC's paddlewheel and ultrasonic flow meters calculate flow based on fluid velocity, adjustments using K values are necessary for each system to achieve the purpose of quantitative injection.

4. Quantitative Pumps: An Alternative Hardware for Quantitative Injection

Besides the quantitative injection systems composed of control boxes, valves, flow meters, and pressure gauges mentioned above, the market also offers equipment capable of executing quantitative control: quantitative pumps.

1 ) What Are Quantitative Pumps?

Quantitative pumps are devices used for accurately measuring and transporting liquids. They operate by using a specific mechanical structure to draw liquid into the pump body and transport a precise volume of liquid to a target location through controlled pressure and flow devices. Typically used in high-precision and stability-required flow transfer scenarios like chemical laboratories, pharmaceutical production, and food processing, quantitative pumps can precisely control the volume and flow rate of transported liquids, preventing inaccuracies. Common types include piston pumps, gear pumps, and peristaltic pumps, each with unique features and applications, requiring careful evaluation and selection based on specific needs and situations.

2 ) Principles of Quantitative Pumps

Quantitative pumps are designed to precisely control flow, based on the pump's operating mode and design. They function by maintaining a fixed volume chamber and appropriate inlets and outlets, ensuring a set amount of fluid is drawn and expelled each cycle. During a pump cycle, the chamber draws fluid from the inlet, then expels it to the outlet through the pump's mechanism (e.g., pistons, gears, screws).

This process repeats in subsequent cycles. The pump's flow and pressure depend on its design and chamber volume, which determines the fluid amount per cycle. Adjusting the chamber volume controls the fluid flow per cycle for precise fluid control. Additionally, adjusting the pump's speed and mechanism can control its output pressure and flow.

3 ) Industrial Applications of Quantitative Pumps

Quantitative pumps have widespread applications in industry and research, including:

- Pharmaceutical Production: For preparing medications, infusions, injections, sprays, etc.

- Chemical Sector: For accurately controlling liquid reagent volumes in chemical labs or industries, ensuring reaction stability and repeatability.

- Food Processing: For precisely adding additives to maintain product quality and safety.

Wastewater Treatment: For accurately adding chemical reagents or medicines to adjust water quality and enhance treatment effects.

- Laboratory Research: For preparing samples, standard solutions, calibration fluids, etc.

Quantitative pumps are essential fluid control devices known for their high precision and reliability, extensively used across various industries and fields.

5. Comparison Between Quantitative Pumps and Quantitative Control Systems

Quantitative pumps and quantitative control systems are both used for precise fluid transfer control but differ in their working principles and application scenarios. Quantitative pumps are mechanical devices that control the volume and flow rate of liquids through the pump's internal mechanical structure. They are suitable for situations requiring precise control of fluid volume and flow rate, such as preparing standard solutions and infusions. On the other hand, quantitative control systems utilize electronic controllers and sensors to control the volume and flow rate of fluid transport. These systems are appropriate for more complex fluid control tasks, such as continuous feeding, heating, and stirring of fluids. Additionally, quantitative pumps require pre-setting of flow and pressure parameters, whereas quantitative control systems can achieve automatic control through programmed settings. Therefore, the choice between quantitative pumps and quantitative control systems should be made based on the specific requirements and context of their application. Generally, quantitative pumps are chosen for precise control of fluid volume and flow rate, while quantitative control systems are selected for more complex fluid control operations.

Due to their principle of operation, quantitative pumps have a limited flow range and applicability. Furthermore, the output flow from quantitative pumps is pulsatile, leading to flow instability. This instability can indirectly affect the performance of downstream devices, thereby impacting the overall production process's efficiency and quality. Therefore, when planning an injection system, it is crucial to carefully consider the characteristics and suitability of these devices based on actual conditions.