What is two-fluid nozzle

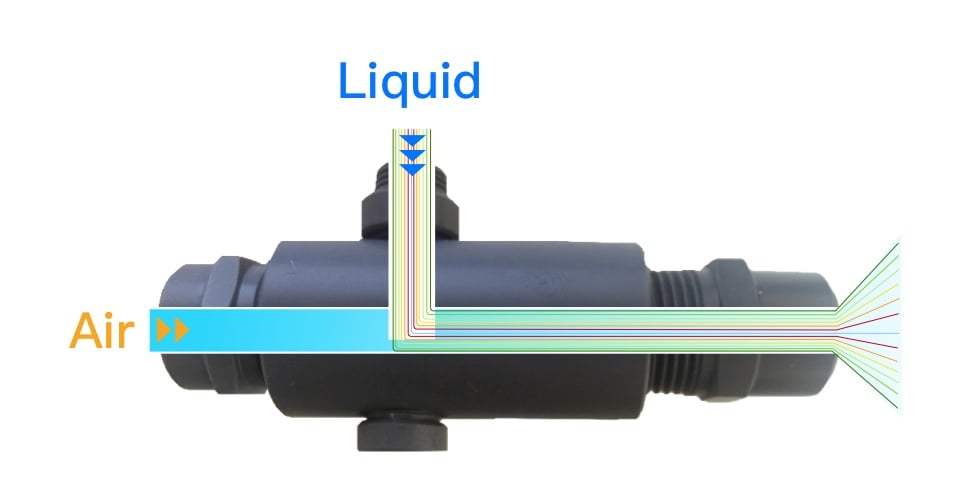

-Schematic diagram of the operation mode of the two-fluid nozzle-

The two-fluid nozzle functions by utilizing high-speed air to crush the liquid, thereby reducing the particle size of the liquid. This process enables the ejection of liquid with smaller particle sizes and higher flow rates.

▲Go back to the Outline of this Article

Features of two-fluid nozzles

1.Enhance liquid atomization by reducing particle size effectively.

2.Expand the adjustable range of liquid flow by controlling gas pressure.

3.Achieve high flow rate spraying and increase impact force significantly.

▲Go back to the Outline of this Article

The principle of the two-fluid nozzle

- Principle overview of two-fluid nozzle

The two-fluid nozzle operates on the basic principle of utilizing high-speed air to crush the liquid, resulting in smaller liquid particles and higher flow rates. This nozzle design not only enhances the cleaning effectiveness but also proves essential in processes where chemical reactions occur on product surfaces. The smaller particle size achieved by the two-fluid spray significantly improves the reaction efficiency of the liquid solution.

For instance, in the PCB etching process, the chemical solution sprayed by the two-fluid nozzle exhibits smaller particle sizes and a larger contact surface area. This characteristic leads to faster and more efficient reactions of the sprayed chemical solution. In contrast, when using other types of nozzles to spray the liquid medicine on the same surface, larger particle sizes may cause certain portions of the liquid medicine to float above others, preventing them from making direct contact with the surface. As a result, some liquid medicine remains unreacted. Consequently, employing a two-fluid nozzle for spraying the chemical solution may require only half or one-third of the amount needed by other nozzle types to achieve similar outcomes.

However, it is important to consider that in the complete mixing of gas and liquid, if the sprayed liquid contains chemical substances, it will undergo oxidation when exposed to air. This oxidation reaction leads to a steeper decline curve in the effectiveness of the liquid medicine, accelerating its decay rate and reducing its available lifespan. As a result, the actual dosage of liquid medicine required may be higher than initially anticipated, necessitating careful consideration when using liquid medicine with two-fluid nozzles.

Furthermore, when the liquid is crushed into fine particles, the flow of gas carries away these smaller particles. Consequently, a portion of the liquid medicine is lost along with the exhaust gas, resulting in increased liquid consumption. Additionally, since the gas carries chemical substances from the liquid, proper treatment of the exhaust gas becomes necessary to ensure environmental safety. [1] [2] [3] [4] [5] [6] [7]

▲Go back to the Outline of this Article

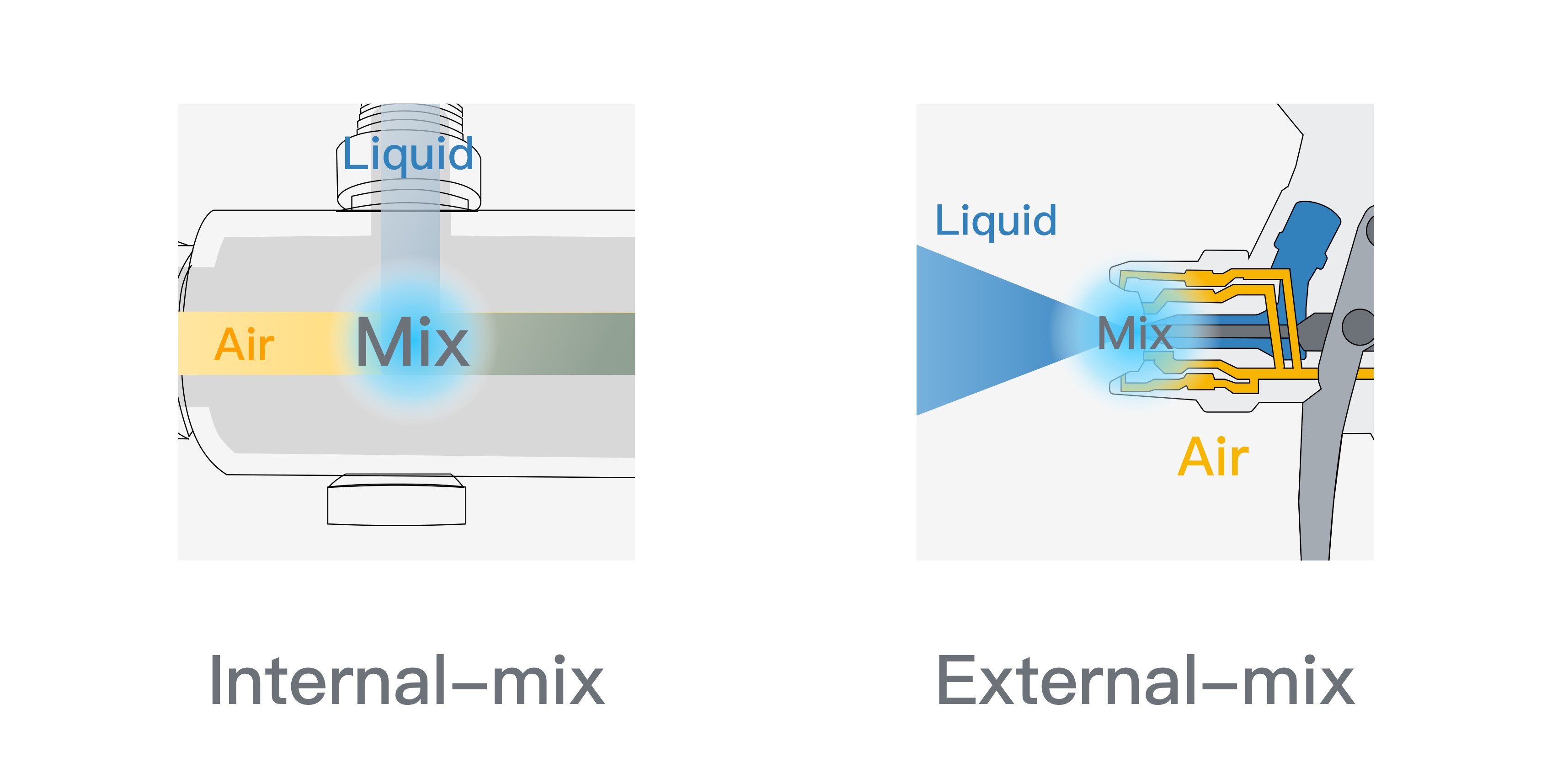

- Mixing method of gas and liquid in two-fluid nozzle

Internal-mix two-fluid nozzles

The internal mixing two-fluid nozzle is a nozzle that enables the mixing of liquid and gas inside the nozzle. It is capable of producing extremely fine liquid particle sizes (with an average particle size below 50µm) and allows for control over the size and distribution of the liquid particles. This type of nozzle is commonly used in industries such as chemical, food, pharmaceutical, and printing, where high precision and efficiency are required. [8]

▲Go back to the Outline of this Article

External -mix two-fluid nozzles

The external mixing type two-fluid nozzle is a nozzle with non-clogging characteristics that allows the external mixing of liquid and gas. A common application of this type is the spray gun, which is a painting tool used to spray paint onto surfaces. The spray gun consists of a nozzle, paint cup, and compressed air machine. When the trigger is pressed, the paint mixes with the compressed air flow and is released in the form of fine spray mist. [8]

▲Go back to the Outline of this Article

- The difference between Internal and external -mix two-fluid nozzles

- Schematic diagram of the division of internal and external mix two fluid nozzles -

Internal mixing and external mixing two-fluid nozzles are commonly used in various industries. These nozzles differ in how they mix gas and liquid. Internal-mixing nozzles blend the gas and liquid inside the nozzle and expel them through a single outlet. They offer easy operation, control, and the ability to achieve high spraying accuracy and uniformity. However, it's important to be mindful of potential clogging and cleaning issues since the mixing occurs within the nozzle.

On the other hand, external mixing nozzles mix the gas and liquid outside the nozzle and then spray them separately through different outlets. These nozzles are capable of delivering higher flow rates and covering a larger spray area, making them suitable for applications that involve coating with larger particles. However, one should be cautious about preventing air bubbles and ensuring spray uniformity when using external mixing nozzles.

Choosing the appropriate two-fluid nozzle type depends on the specific requirements of the application. Internal mixing nozzles are ideal when precision and uniformity are crucial, while external mixing nozzles are more suitable for applications that demand a larger coverage area and higher flow rates. It is essential to perform regular cleaning and maintenance of the nozzles to ensure optimal performance and prolong their lifespan. [8]

▲Go back to the Outline of this Article

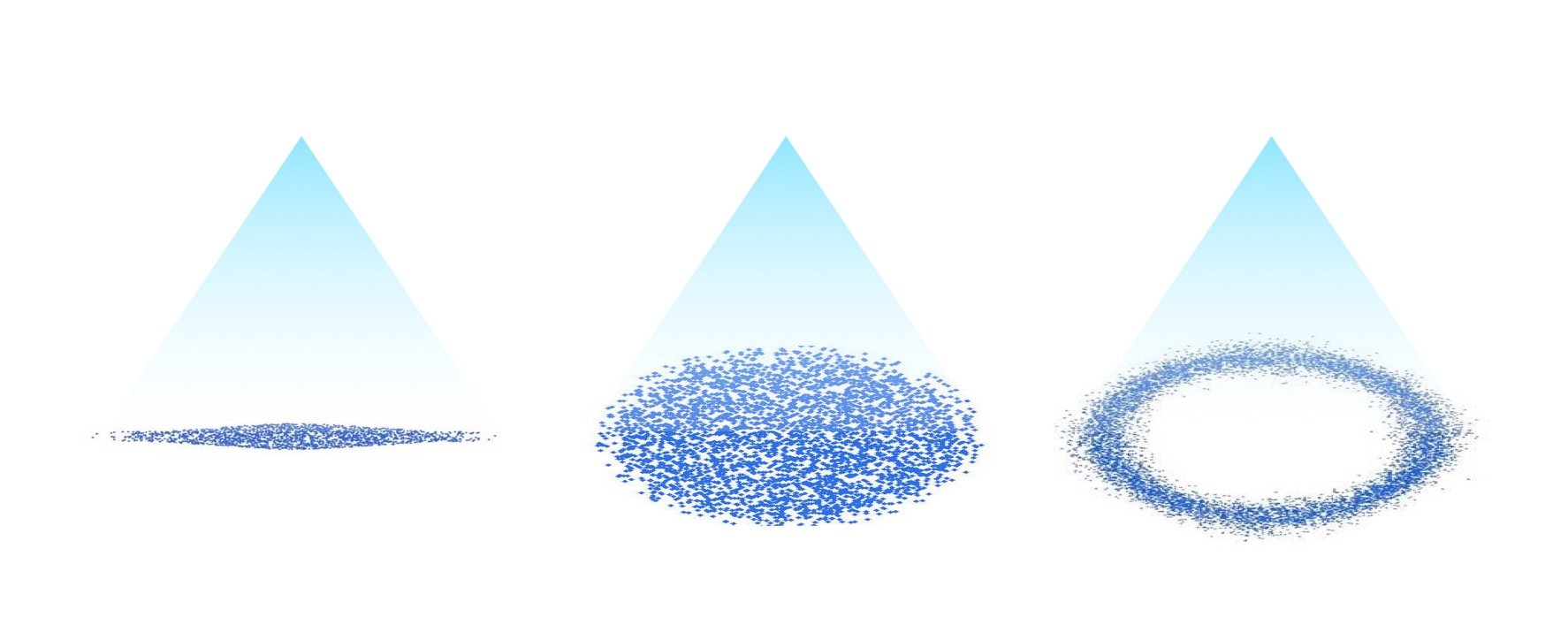

The spray pattern of two-fluid nozzles

-Schematic diagram of the spray shape of the two-fluid nozzle-

Two-fluid nozzles offer different spray shapes, including fan-shaped, solid cone, and hollow cone patterns. Typically, these nozzles are designed to produce a solid cone spray with uniform distribution and fine atomization. However, with the appropriate nozzle structure design, they can also generate fan-shaped and hollow-conical sprays.

It is important to note that two-fluid spraying is influenced by the surrounding environment, particularly due to the small size of the spray particles. As a result, the spray shape may not be maintained when spraying at certain distances. Factors such as air movement, humidity, and other environmental conditions can impact the trajectory and dispersion of the spray. Therefore, it is crucial to consider the specific environmental factors when utilizing two-fluid nozzles and adjust the spraying parameters accordingly to achieve the desired spray shape and coverage.

▲Go back to the Outline of this Article

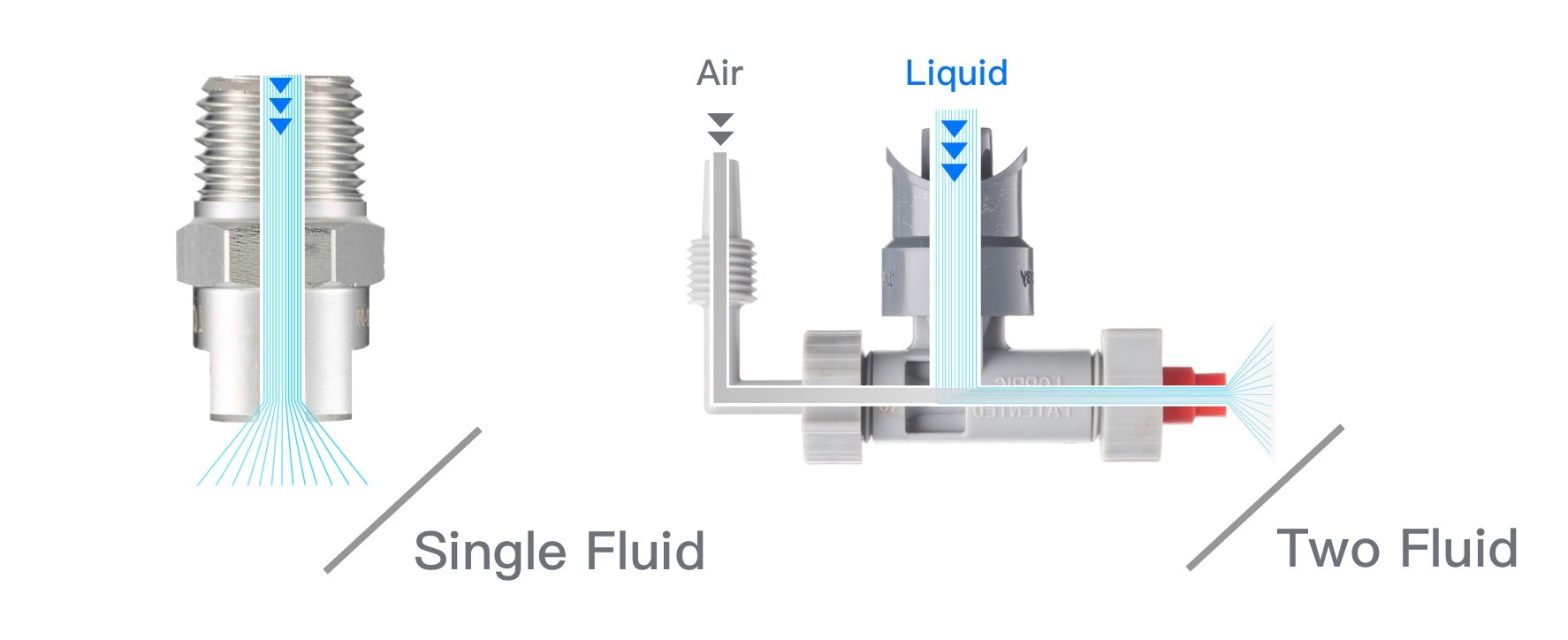

Identifying One-Fluid and Two-Fluid Nozzles

-Schematic diagram of the principle division of one-fluid and two-fluid nozzles-

The main difference between a single-fluid nozzle and a two-fluid nozzle lies in their internal structure. A single-fluid nozzle has only one passage, while a two-fluid nozzle has two separate passages for gas and liquid. This difference affects their functionality and applications. Due to the need for air and liquid sealing, two-fluid nozzles are often designed with multiple components, which results in higher costs compared to single-fluid nozzles. [8] [9]

▲Go back to the Outline of this Article

Advantages of two-fluid nozzles

1. It is capable of generating a fine spray with smaller particle sizes (average size below 50µm) compared to a single fluid nozzle, and can operate at low pressures (0.1~0.3MPa).

2. Ensures consistent and even distribution of the spray. [8] [10]

▲Go back to the Outline of this Article

Disadvantages of two-fluid nozzles

1.Intricate design

2.Demands high-pressure gas

3.Prone to clogging

4.Requires precise machining

5.Costly

6.Due to the fine particle size of the sprayed liquid, it can easily lead to vaporization, resulting in the surrounding air becoming saturated with particles. When spraying corrosive liquids, complete isolation of the space is necessary, and increased liquid consumption is inevitable due to the vaporization process.

▲Go back to the Outline of this Article

Applications of two-fluid nozzles

- Two fluid etching

In the wet PCB manufacturing process, when there is a need for etching narrow traces with line width and spacing less than 25μm, a two-fluid nozzle is often used to facilitate the entry of chemical solution into these extremely narrow gaps. By utilizing high-speed air to break the liquid, the two-fluid nozzle creates smaller liquid droplets with higher flow velocity. This characteristic enables the uniform and efficient spraying of the chemical solution, resulting in the desired reaction. As a result, the two-fluid nozzle becomes a preferred choice for specific processes in the PCB industry.

- Enhancing Exhaust Gas Treatment with Two-Fluid Nozzles

With the advantage of small droplet size, two-fluid nozzles are widely employed in the treatment of exhaust gases, particularly for addressing the issue of PM2.5 particles.

- Cleaning Applications of Two-Fluid Nozzles

In cleaning applications, the use of high-pressure equipment can be costly. To address this, two-fluid nozzles are often employed due to their ability to achieve high spray velocities without the need for high pressure. An example is the application of two-fluid nozzles in the printing industry for cleaning ink in screen cleaning machines.

- Other Applications of Two-Fluid Nozzles

These versatile nozzles find applications in smoke control, paint application, humidification, lubrication, gas cooling/conditioning, and atomization.

[11] [12] [13]

▲Go back to the Outline of this Article

Contact Us

Citations

1. ⌃ Thermopedia-ATOMIZATION (2011-02-22)

2. ⌃ Sciencedirect-Atomizer Nozzle

3. ⌃ Sciencedirect-Gas–liquid two-phase flow rate measurement with a multi-nozzle sampling method (2015-11)

4. ⌃ Researchgate-Figure 5 - available via license: Creative Commons Attribution 4.0 International

5. ⌃ Large eddy simulation of the two-phase flow pattern and bubble formation process of a flow mixing nozzle under a gas–liquid mode (2019-09-11)

7. ⌃ Wikipedia-Spray drying

8. ⌃ Wikipedia-Spray nozzle

9. ⌃ Two Fluid Atomization Fundamentals (2017-07-23)

10. ⌃ Sciencedirect-Two-fluid spray atomisation and pneumatic nozzles for fluid bed coating/agglomeration purposes: A review (2008-07-14)

11. ⌃ Time-resolved 3D imaging of two-phase fluid flow inside a steel fuel injector using synchrotron X-ray tomography (2020-05-26)

12. ⌃ Numerical simulation of the two-phase flow produced by spraying a liquid by a nozzle (2017-07-25)

13. ⌃ Sciencedirect-Internal two-phase flow and spray characteristics of outside-in-liquid twin-fluid atomizers (2021-03-25)