Overview

- Diversity of Thread Standards: Highlights the variety and global adoption of certain thread standards due to globalization.

- Tapered vs. Parallel Threads: Discusses the unique features and applications of tapered and parallel threads, focusing on their sealing and tensile strengths.

- American vs. British Standards: Compares NPT/NPS and BSPT/BSPP standards to clarify differences and uses.

- American Tapered and Parallel Threads: Examines the importance of NPT and NPS standards for specific industrial needs.

- British Tapered and Parallel Threads: Explores BSPT and BSPP standards, emphasizing the importance of understanding their distinct characteristics for proper selection.

Around the world, a wide variety of thread standards exist due to different applications, industries, equipment, equipment suppliers, and component suppliers. However, globalization has led to the adoption of certain thread standards by most suppliers for equipment or components. This article primarily organizes and introduces several globally prevalent thread standards, allowing everyone to easily understand and identify these common thread standards.

1. Tapered vs. Parallel Threads

Thread appearance broadly categorizes into tapered and parallel threads, each with distinct characteristics and application differences.

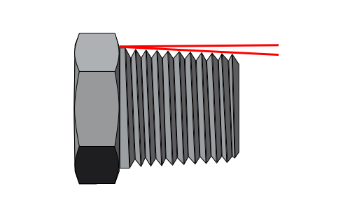

Tapered Threads

- Shape: Tapered threads have a conical profile, wider at the top and narrower at the bottom, with a slope on the sides.

- Size Variance: They can lock even if there is a size discrepancy between the male and female threads. A larger male thread results in a shallower lock, and vice versa, but it can still secure tightly. This allows for a greater tolerance in sizes while maintaining a degree of sealability.

- Pressure Resistance: Without sealants, tapered threads are more pressure-resistant and less prone to leaks compared to parallel threads, offering a level of leak prevention between two components.

- Applications: They are commonly used in restricted spaces, uneven or curved surfaces where sealants can't be used, such as nozzles installed on pipes, which typically employ tapered threads for their leak prevention capabilities.

[1]

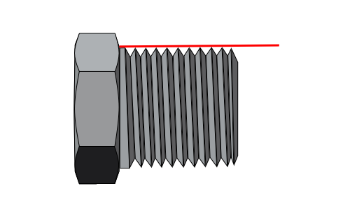

Parallel Threads

- Shape: Parallel threads have a rectangular profile, with sides that run parallel to each other.

- Size Matching: The size of the male and female threads must match exactly to lock.

- Locking Depth: If the sizes match, the thread can be fully engaged and locked very tightly. However, with greater tolerance in sizes, a male thread may not lock into a female thread.

- Tensile Strength: The characteristic of being able to lock fully provides tensile strength, pulling two surfaces together tightly, such as in flanged joints. However, without sealants, parallel threads lack sealing capabilities.

- Sealing Requirements: Typically, without sealants, parallel threads cannot achieve a seal. When a seal is needed, parallel threads must be used with sealing components like O-rings to tighten and seal effectively. Sometimes, parallel male threads are used with tapered female threads to achieve a low-pressure seal.

[2]

2. American vs. British Standards

The two predominant international thread standards are developed by the United States and the United Kingdom.

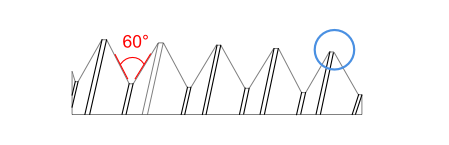

American Standards (NPT/NPS)

- American National Standard Pipe Thread Standards: The American National Standard Pipe Thread Standards, known as National Pipe Thread standards, include both tapered (NPT) and parallel (NPS) threads. They are used for rigidity, pressure sealing, or both in pipes and fittings, mainly in North America.

- Thread Angle: The angle between the thread's side and the perpendicular line to the bolt's axis is 60 degrees, indicating the angle at which the threads intersect.

Thread Peaks and Valleys: The highest point of the thread is known as the peak, and the lowest point is called the valley, which are designed to form sharp angles for effective engagement.

- American Tapered Thread (NPT): Officially named the American National Standard Taper Pipe Thread, NPT is a widely used standard for tapered threads in industrial components. It is often employed for sealing industrial parts where no sealant is necessary, offering a broad range of applications.

- American Parallel Thread (NPS): Referred to as the American National Standard Straight Pipe Thread, NPS is the standard for parallel threads in industrial components. It is used when rigidity is required and sometimes for low-pressure sealing by fitting a parallel male thread into a tapered female thread with a sealant.

[3][4]

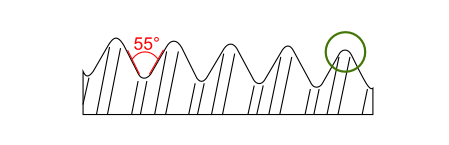

British Standards (BSPT, R/BSPP, G)

- British Standard Pipe (BSP): An internationally recognized thread standard, including both external and internal threads, used extensively for piping and pipe fittings. It is as prominent as the American NPT standard and frequently serves as the go-to specification for piping systems.

- Thread Angle: The angle of the threads is 55 degrees, which is a distinguishing feature compared to the 60 degrees of American standards.

Thread Peaks and Valleys: Unlike the sharp angles found in American standards, BSP threads have rounded peaks and valleys, contributing to different sealing and engagement characteristics.

- British Tapered Thread (BSPT): Also known as "R thread," BSPT (The British Standard Pipe Taper) remains a common term despite the adoption of the "R" designation. It's widely used for creating seals in piping without the need for additional sealing components.

- British Parallel Thread (BSPP/G): The British Parallel Thread, known as BSPP or "G thread," alongside variations like BSPM, is the standard for parallel threads in the UK. Initially introduced as BSPF to differentiate from BSPT and avoid confusion with similar American standards, it was later renamed BSPM. Despite these changes, BSPP remains the predominant term for British parallel threads, with "BSP" referring to both BSPP and BSPT types.

[5]