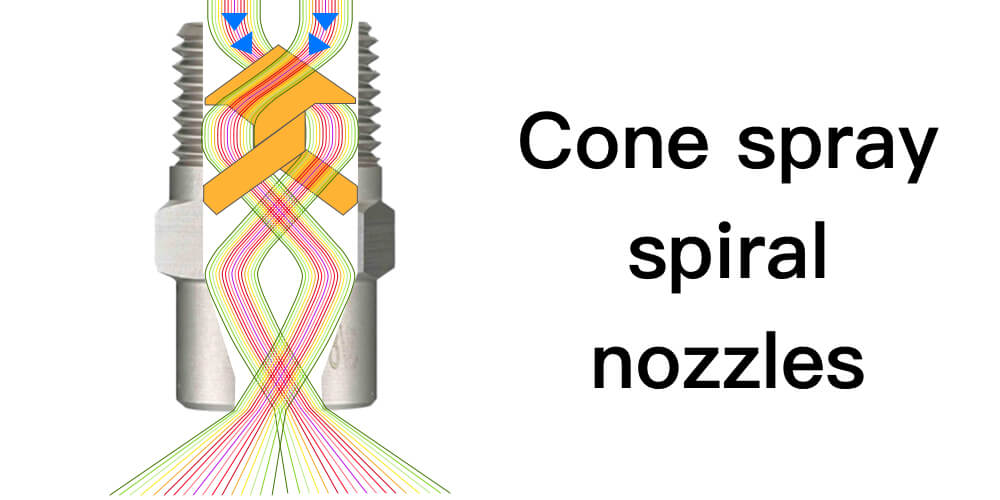

For perfect cone shape spraying, the structure inside the cone spray nozzle must include 2 features, a chamber with a machined curved structure and a multi-slotted core or an X core set in the chamber. After the liquid flows to the nozzle from the pipe forced by pressure, it will flow through the multi-slotted or X core (aka spoiler.)

It will be separated into 2 or more streams. These separated streams will be sprayed out (thrown out) by the centrifugal force. When they pass by the spout. The sprayed-out liquid will eventually become a cone-shaped spray.

Through adjusting the fluid-structure and size of the inner core and the curved structure of the spout, the flow rate, angle, and distribution could be possibly adjusted. After the liquid flow will be separated by the spoiler of the inner core and whirl inside the nozzle, it will spray out at a certain angle. The liquid will be atomized after being sprayed out from the cone spray nozzle. Because of the difference in structure and principle, the particle size of the sprayed liquid from the cone spray nozzle will be larger than the fan spray nozzle, and its distribution could be formed as a circle surface.

* Multi-slotted core: It guides the liquid flowed into the nozzle with multipath and makes more even spray distribution. Commonly, multi-slotted cores are more difficult to be made by machining which make it more expensive. (as the main image of the article)

* X core: it makes double path flow and leads that there is larger flow on certain both sides than others. (as below image)

Contact Us

Products you may also like