It has already been many years since the use of paddlewheel flowmeters became a staple in many industries. The relatively convenient installation with both horizontal and vertical measuring options, relatively large range of flow speeds measuring ability, as well as having both the accuracy of electronic flowmeters but with an equally low price, all contributed to it being a favorite of such a broad user base.

However, after having nearly 30 years of experience dealing with fluid-related technology and having collected over a thousand customer suggestions and learned from their onsite experience, we at LORRIC discovered that the all common paddlewheel flowmeters still have many ways in which to improve, with room to ponder user experience enhancement.

From the insights we gained from our research of longtime users, we found out that the paddlewheel flowmeter has several shortcomings:

◉ Signal sensitivity is low:

The most commonly seen paddlewheel flowmeter has 4 blades, each blade has a magnet, and between each blade there’s a space of 90 degrees. Therefore, there can only be a signal once with every movement of 90 degrees, which means that the signal is not responsive enough. During the rotation time of the paddlewheel between two blades, as there is no magnetic field to be sensed, the device is unable to distinguish if there is a no response measurement or detect situations when the paddlewheel is absent.

◉ Inability to know the direction of flow:

One of the characteristics of the paddlewheel flowmeter is that it can sense flow speeds at both positive and negative flow directions. However, in order to know the flow direction, certain methods need to be undertaken, such as the installation of see-through flow-showing pipes. For the onsite manager, this is a big cause for inconvenience to say the least, and may also increase on-site management costs.

◉ When the paddlewheel flowmeter gets damaged, the signal will only display “zero”:

Except for situations in which the flow is really miniscule or there really is no flow, there is also a chance that because of problems in the pump, pipes, equipment itself, or because of crystallization or wear and tear, the paddle will fall off or become damaged. Generally speaking, paddlewheel flowmeters are unable to tell you if or when flow is displayed as zero, is it because of the latter or the former? That drawback is a big factor when it comes to troubleshooting a failed system.

Except for the above points, for the sake of lowering manufacturing costs, some paddlewheel flowmeter manufacturers will reduce the amount of rare earth magnets used. That in turn will reduce the amount of signals received to only once or twice per rotation, which will reduce the signal sensitivity even further. On top of that, because of uneven weight distribution, the rotation turning speed will be uneven, which will impact both accuracy and lifespan.

LORRIC emphasizes customer feedback, and has an intimate persistence towards product quality. Thus in order to improve customer user experience, LORRIC’s R&D team made a new innovative design(patent pending) which ameliorates regular paddlewheel flowmeter shortcomings, making the paddlewheel flowmeter capable of more precise flow speed and flow rate measurements.

▲Go back to the Outline of this Article

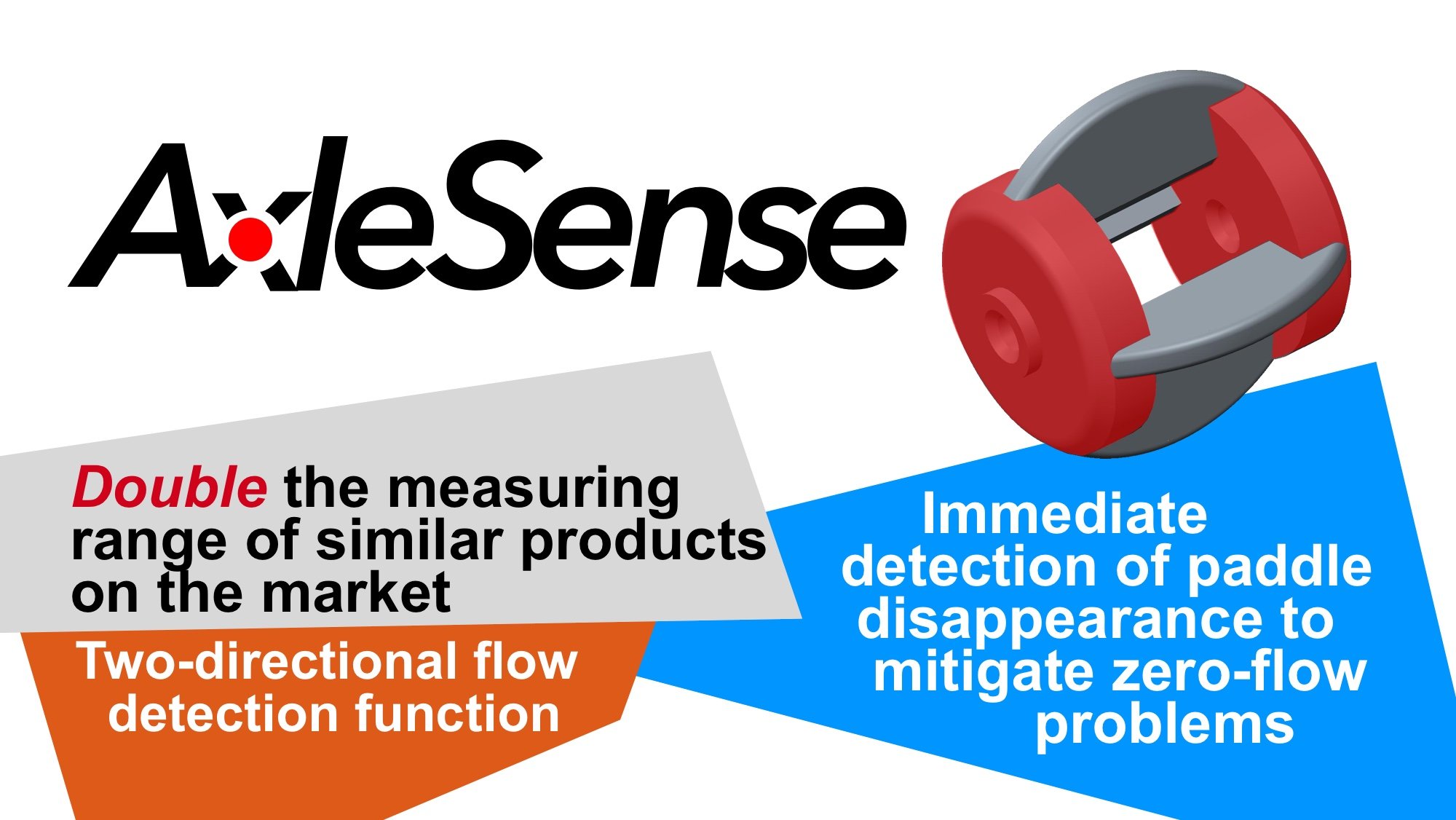

The Patented AxleSense Technology

LORRIC improved upon the conventional design of placing the magnet on top of the paddle, changing the measuring principle from sensing the time difference between the magnet on top of the paddle passing the inductor, to the paddle’s rotation direction itself, thus creating a unique patented “AxleSense paddle”. On top of that, LORRIC redesigned the flow measurement algorithm, thus introducing the new patented “AxleSense” technology, which allows for a substantial upgrade in the sensing capabilities of extremely small flow rates, as well as the immediate monitoring of any paddle abnormalities.

The Patented AxleSense Technology Features

A wider flowrate detection range (0.15m/s~10m/s)

In traditional paddlewheel flowmeters, the sensing magnet is placed on top of the paddle, which means that during low liquid flow speed phases, flowrate detection has a large margin of error, even to a level of not being able to detect any flow at all. As seen in the diagram to the left, when flow speed is below 0.3 m/s, it becomes relatively harder to detect flow speed, with an error 36.33% of reading. Flow speeds of under 0.3 m/s will see a margin of error reaching 50% with substantially large fluctuations, which means that the actual flowrate can be multiple times over the received data, which makes the data unusable as a reference.

LORRIC’s paddlewheel flowmeter however, thanks to its patented AxleSense technology, utilizes directional change to detect flow, and a signal can be sent within 3 degrees of the paddle’s rotation, making for denser signals and thus a higher resolution. That means that even under slow flow speeds, a steady stream of measured signals persist, with a broader flow measurement range and a full scale error rate of 0.5% . Under low flow speeds of 0.3 m/s, thanks to the sensitivity of the paddle, its rotation allows the full scale error to be controlled at 9%, and maintain that up to an even lower 0.15m/s flow speed. LORRIC’s paddlewheel flowmeter can maintain a low margin of error when monitoring flow, and provide users with a more extensive application range.

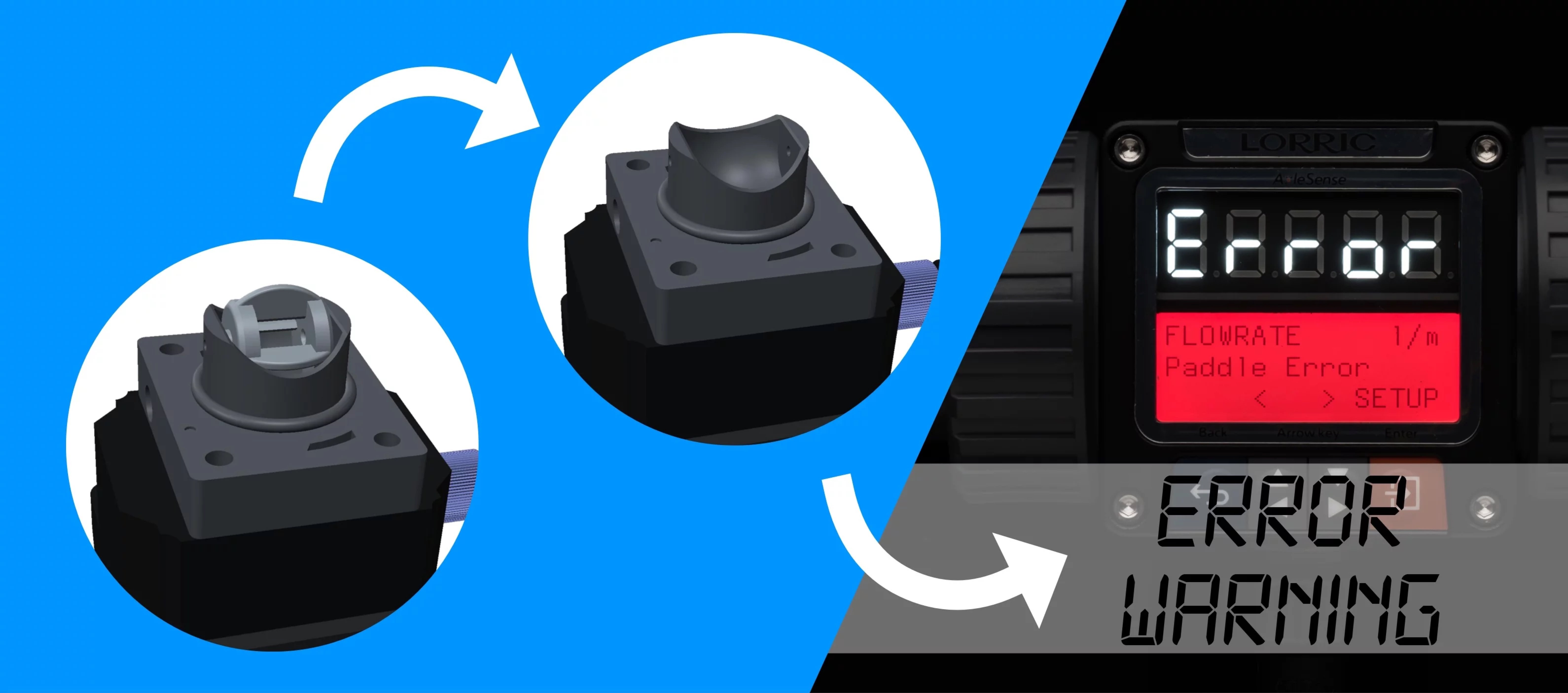

An active smart mechanism for the detection of flow problems that arise from paddle disappearance

A flowmeter’s inability to detect flow may originate from problems in the pump, pipes, the equipment itself, or because of problems of crystallization, wear and tear or fracturing of the paddlewheel flowmeter that may cause the paddle to be damaged or fall off. LORRIC’s patented AxleSense technology allows for even weight distribution and for balanced rotation. In addition, through the sensor’s algorithm technology, the paddle’s status can be detected, and any abnormalities are actively detected straight away. Therefore, clear information is offered for the on-site manager to see, and not just a simple, passive “zero-flow” notice. Regarding industry 4.0 users, LORRIC’s paddlewheel flowmeter’s detailed information can be integrated with the factory’s management system, which helps on-site workers to solve any flow problems even faster.

*DISCLAIMER: Please be aware that magnetic fields or residual magnetism may cause interference to the flowmeter which may result in damage if they are used near the installation site. The purchaser must determine the applicability of the product for its desired use and assumes all risks in connection therewith. LORRIC assumes no responsibility or liability for any omissions or errors in connection with the use of its products. The alarm used to detect paddle damage or loss is intended to assist on-site operators to find out what is causing equipment abnormalities. Because there are a myriad of variables involved with on-site operation and magnetic fields that come from other equipment, the alarm function is liable to fail. Please do not take the alarm function as a single source for monitoring your flow system. Please contact LORRIC for advanced help.

Two-directional flow detection

LORRIC’s patented AxleSense technology uses the paddle’s direction to detect the flow’s fundamentals, while at the same time supplying direct information about the flow direction inside the pipelines. This in conjunction with integration with the factory’s management system, which makes on-site management more convenient.

▲Go back to the Outline of this Article

LORRIC’s featured patented AxleSense Vs. traditional paddlewheel flowmeters comparison table

|

LORRIC patented AxleSense

|

Regular paddlewheel flowmeter |

| Two-directional flow detection |

Yes |

No |

| Response signal |

Dense |

Large intervals |

| Paddlewheel weight |

Even |

Uneven |

| Screen indicator lights |

A colored trio of alarm indicator lights: green, orange, red |

No specialized colors |

| Screen display |

LED-5 digits LED/LCD- 16x3 LCD backlight display |

LCD Only |

| Measuring range |

Low speeds measurable, wider range |

Low speeds are hard to measure, narrower range |

| Measuring margin of error |

High speed margin of error is low, low speed margin of error is small |

High speed margin of error is low, low speed margin of error is large |

▲Go back to the Outline of this Article

➔ Understand the LORRIC patented AxleSense paddlewheel flowmeter further

Contact Us

Products you may also like